Results 1 to 10 of 26

-

07-14-2015, 11:21 PM #1

Dental Handpiece Motors (Marathon Micromotor)

Dental Handpiece Motors (Marathon Micromotor)

Hi Guys,

First time poster, long time reader.

I am wanting to take the plunge into razor restoration, however I am limited by a distinct lack of workspace at my house. Ideally, I would like to buy a bench grinder/buffer, however I only have a single garage with no room for a workbench or anything of the sort. This has caused me to consider smaller, portable options such as rotary tools (Dremels etc). Although I do like Dremels, I understand that they are not built as well as in years gone by, often burning out after 12 months of use.

I'm not wanting to spend a lot at this stage. I have been trialling sandpaper techniques with great success, however this process is painfully slow. I'm just after something that could help me save some time and produce a finish as good as sanding by hand.

Whilst researching rotary tools, my wife gave me the idea of using a dental hand-piece (she works at a dental practice). This led me to inexpensive dental micromotors such as the one below:

http://www.ebay.com/itm/35K-Dental-L...ee2&rmvSB=true

Does anyone have any experience with similar devices, or even this one in particular?

I feel that I should note that I am not currently looking to do any extensive structural restoration such as pitting removal etc.

Thanks so much guys.Last edited by Orange36; 07-15-2015 at 12:20 AM.

-

07-15-2015, 12:12 AM #2

Think this URL link works.

35K Dental Lab Motor Electric Micromotor Marathon Polishing Unit 35K Handpiece | eBayShave the Lather...

-

07-15-2015, 12:27 AM #3

For Several Years I only used hand sanding and the assistance of a hand held 'palm sander' plugged into a GFCI receptacle.

I got good results.See here:

http://straightrazorpalace.com/custo...n-cleanup.html

Even after building my buffer See Here:

http://straightrazorpalace.com/works...-part-one.html

I still do a lot of work by hand/even using the palm sander.

Some of the finest cleanups of straight razors have been done without power tools.

As with 'Everything' involving straight razors it comes down to 'Personal Choice'.

Have Fun and Enjoy the Ride! It's a long strange trip/but it's well worth the journey!

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

07-15-2015, 12:31 AM #4

I would say go with a Foredom. Cry once, as they say.

Foredom Jewelers Flex Shaft Kit 2230 SR 1 6hp 110V New | eBay

-

07-15-2015, 12:38 AM #5

It is only my opinion , but I feel such rotary tools,grinders and buffers have little to offer the "novice" in the restoration process .Hand sanding and hand tools are not only safer but the patience needed to use them efficiently will pay dividends down the road if and when you decide to upgrade.

"It is easier keeping a razor honed than honing a razor."

-

07-15-2015, 01:07 AM #6

I'm really appreciating the responses guys, highly informative!

-

07-15-2015, 01:16 AM #7

To ease the pain of hand sanding, make a sanding jig from a scrap of wood,a tongue depressor for a shallow ledge, counter sink and expxy rare earth magnets to hold the blade and duct tape to cover the magnets. Add a assortment of backers for your sand paper and you have made your life much easier.

"It is easier keeping a razor honed than honing a razor."

"It is easier keeping a razor honed than honing a razor."

-

The Following User Says Thank You to Wirm For This Useful Post:

MikeT (07-15-2015)

-

07-15-2015, 09:07 AM #8

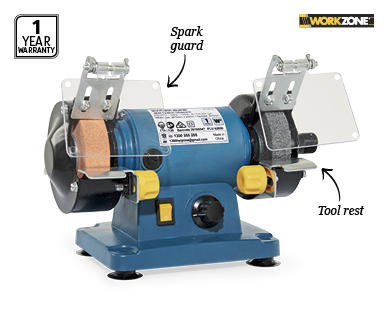

Just had a quick browse through an ALDI catalogue, it turns out that they will be stocking mini bench grinder/buffers this Saturday for $40. Forum reviews suggest that it's a great little machine. Might give this a go if they have any stock remaining. If they do, I'll be sure to follow up with some progress images to let you all know how it went.

Last edited by Orange36; 07-15-2015 at 09:08 AM. Reason: spelling fail

-

07-15-2015, 01:27 PM #9

And what I still use most of the time:

http://straightrazorpalace.com/works...storation.html

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

cudarunner (07-16-2015)

-

07-15-2015, 01:44 PM #10Senior Member

- Join Date

- Oct 2010

- Posts

- 26,211

Thanked: 8626

I dunno why some say the Dremels won't last. I have two, a variable speed with manual adjustment, not the one with the LCD screen!( Those don't last!) and a single speed one which is fixed, uses a cable, and is variable speed-controlled with a sewing machine pedal. 10 and 6 years later, they are both fine. I use them for many tasks in my automotive shop as well as some on razors, blades, scales, pins, etc. The Foredom is nice, but then, getting proper collets, etc. Seems a bit overkill and prestigious for the purpose. I try to stay away from microchip driven things as there is where the smoke usually comes from. Bearings, brushes, armatures cables are all replaceable on the Dremels as well, although I have not needed any yet.

This is from my experience. YMMVLast edited by sharptonn; 07-16-2015 at 01:11 AM.

Nothing more to say........

38Likes

38Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote