Results 1 to 9 of 9

Thread: Experimenting

Threaded View

-

07-25-2015, 08:34 PM #1

Experimenting

Experimenting

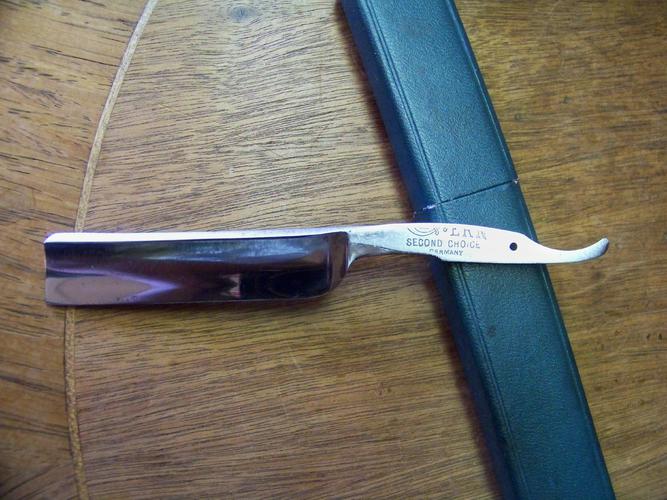

I was reading some stuff about spiral patterns on gun barrels done with orbital sanders and thought that it looked really nice and figured I would try it on a razor tang. The razor I decided to try it on was an Ern Second Choice that had quite abit of rust on it. I wasn't able to get the pitting out since it was pretty deep and the razor wasn't all that thick. I took the sander to the tang and sides of the spine and mirror polished the top of the spine and top & bottom of the tang. Ended up with a bunch of tiny circles tightly locked together instead of big swirls. Kind of has a look to it like galvanized steel. It really sparkles in bright light that doesn't show up in the photos. Razor still has a slight frown in it that will have to come out, but the hard part will being trying to figure out the scales for it that will go with the pattern on the tang. I have a few garbage razors that I think I will have to do some more experimenting on.

7Likes

7Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote