Results 1 to 10 of 39

Thread: Home made Micarta......

Threaded View

-

09-07-2015, 02:57 PM #1I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284 Home made Micarta......

Home made Micarta......

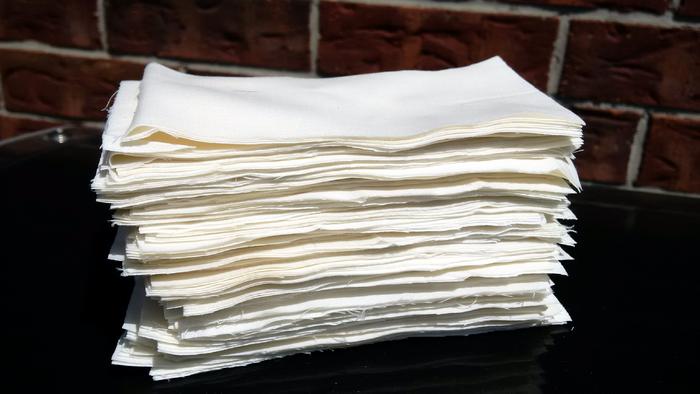

Ok Fellas, I'm turning to you for some advice. I've always thought about making a solid block of Micarta to turn a brush handle out of, and last night I made an attempt. I cut so much freaking Linen, I wasn't about to count how many layers I had. I had 3" of material, and that's 3" with me pushing it down with my hand. I made a form, as you will see from the pics, soaked all the pieces and clamped it as hard as I could. I gave it the night to cure and took it out this morning to see that I only had 1 1/4" of material to work with. I couldn't believe I compressed all that down to 1 1/4".

My question to you guys is, do you think it's possible to add more material and epoxy to this existing blank, to get to the size I need. I was originally shooting for 2". After seeing it was not big enough, my initial thought was, oh well I'll just adhere a cool piece of wood or acrylic to the side of it to make up for the material I need.

Whatcha think guys?

Burls, Girls, and all things that Swirl....

Burls, Girls, and all things that Swirl....

73Likes

73Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote