Results 1 to 10 of 17

-

10-01-2015, 05:00 AM #1Junior Member

- Join Date

- Feb 2015

- Location

- United States

- Posts

- 10

Thanked: 0 Best way to cut a blade, making a shorty

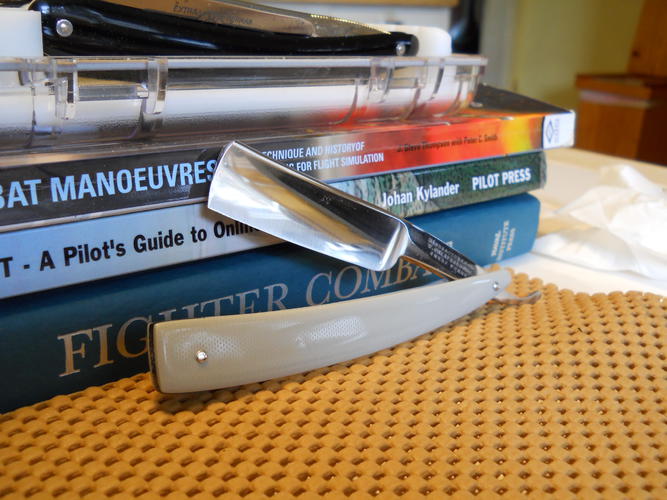

Best way to cut a blade, making a shorty

What's the best way to cut a blade. I picked this one up and was thinking of making a shorty. And any advice on rehoning. Should I go and set a new bevel would taking the front off change the current bevel? And if you have a shorty post some pics

-

10-01-2015, 05:28 PM #2The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,736

Thanked: 480

I NEVER cut a shorty. THe heat generated would destroy the temper of the blade.

Options are lots and lots of hand sanding on course paper, or as I do it, slow speed grinding wheel.

I do a 1750 rpm motor driving a 2" pulley off to a 6" pulley, turning a 6" wheel and still dip in cold water very frequently.

-

10-01-2015, 05:42 PM #3The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,736

Thanked: 480

Some examples of my "shorts" can be found here. If somebody wants to just grab the images and put them in, you can delete this particular post.

http://straightrazorpalace.com/custo...ie-razors.html

and this little wonder...

http://straightrazorpalace.com/works...no-return.html

-

10-01-2015, 06:12 PM #4Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,016

Thanked: 631

I wrap a damp paper towel around the blade and use a dremel with a cutting wheel. Do not use constant pressure. Cut a little and back off then cut again. Repeat until cut thru. Make sure blade does not get too hot. Once cut you can use à sanding wheel to shape the tip.

-

10-01-2015, 07:50 PM #5

A friend of mine does them something like that, but IIRC he uses masking tape on the area, marks it with a sharpie as a guide, and does the dremel thing, as you do, but with a glass of water to dip the blade into to avoid overheating it. In any case, make sure the wheel is spinning in the direction away from the edge for best results.

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

10-01-2015, 08:18 PM #6

I have been thinking of doing this as well! I am planning on using a grinder with water close by to prevent overheating. Remember to take your time, also I plan on doing it with no gloves so I can feel any heat that is building up.

-

10-01-2015, 08:32 PM #7Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,016

Thanked: 631

That's why I use the wet paper towel. It keeps it from overheating. If you use the glass of water method the blade may get too hot before you dip it in the water.

-

10-01-2015, 10:08 PM #8

As bouschie and JimmyHAD advise , I also use a dremel to shorten the blade and a 1 inch belt sander with 320 grit belt to profile the end. Take it slow and keep it wet and cool , cutting from the spine to the edge being cognisant of direction of the wheels spin .

"It is easier keeping a razor honed than honing a razor."

"It is easier keeping a razor honed than honing a razor."

-

10-01-2015, 10:11 PM #9Who's that guy think he is...

- Join Date

- Jun 2011

- Location

- The North Coast, Ohio

- Posts

- 2,455

Thanked: 146

I cut one down using a Dremel with the blade spinning away from the edge and held an ice cube on the opposite side of the cutting wheel. It worked great.

Luck is a matter of preparation meeting opportunity. ~Lucius Annaeus Seneca

-

10-01-2015, 10:12 PM #10

Dremel, cutoff wheel, and do not keep the wheel in one place stationary. Also cut the edge first.

You should be fine.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote