Results 1 to 10 of 21

Thread: Make me smile

Threaded View

-

11-07-2015, 02:52 PM #1Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215 Make me smile

Make me smile

How I made a frowning razor, smile.

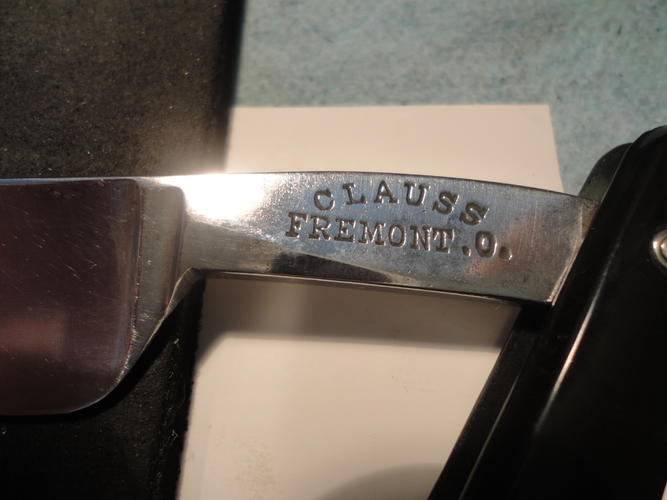

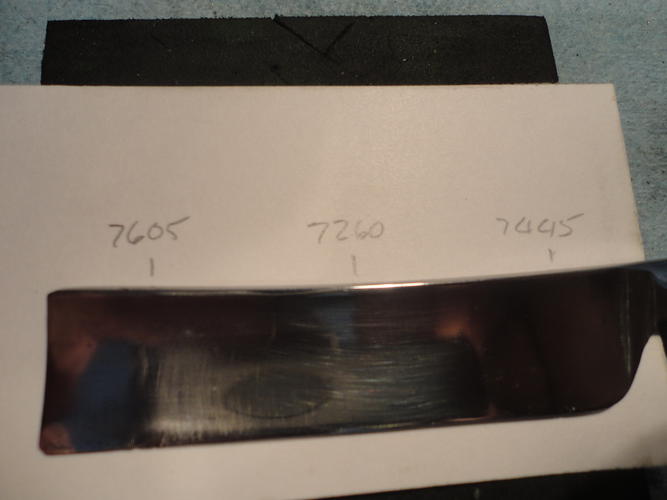

Recently on a couple of other threads the subject of how to hone a razor into a smile. Recently I picked up a Clauss razor in the wild for $15, yes they are out there, and it looked a little lob sided. Measuring it, I discovered it had a bit of a frown and wider toe (.7580), than heel (.7445), a swayback spine, and a muted tip, a good candidate for a smiling razor.

So I thought I would post a photo tutorial of the process. It is pic heavy and will take 3 postings. Sorry about the shaky pics, trying to hold the razor, tools and camera, needed a third hand.

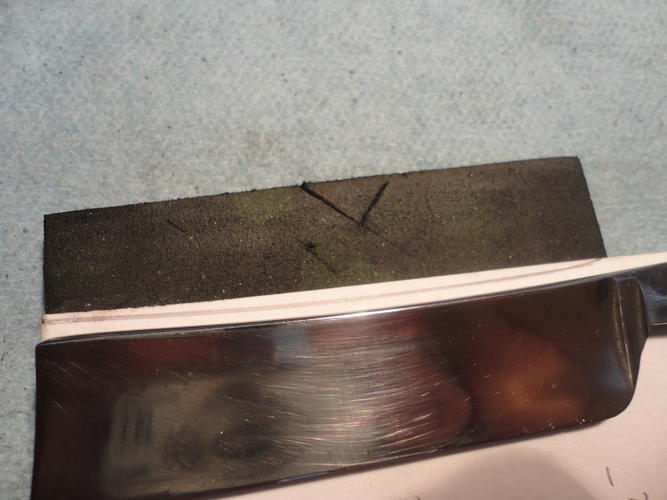

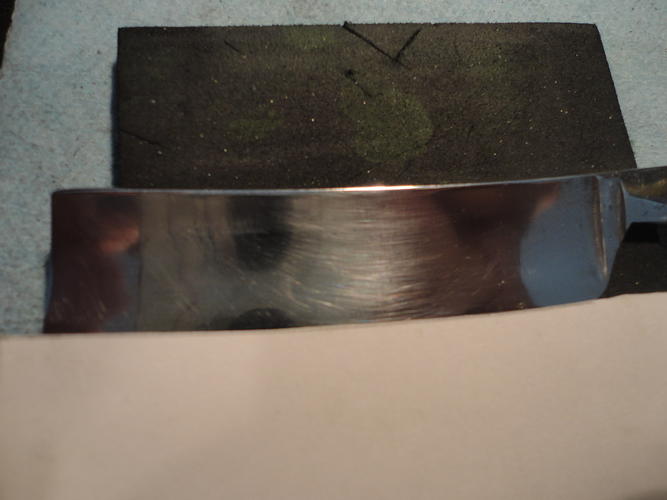

My plan was to make the edge match the spine. I traced the spine on a piece of cardboard, and cut it out, to create a pattern, trace the spine arc with a sharpie on to the blade edge, using the lowest part of the blade (.7260). as the middle. The Sharpie mark is just a guide, the true shape and width is formed by measuring and shaping a little at a time.

Here's the razor as purchased with a little bit of clean up, just polish and some Chrome Ox on the buffer.

Notice the wonky blade and the slight frown.

Some good Measurements confirm my suspicions.

Trace the spine shape

Copy onto the edge

Continued Make Me Smile 2Last edited by Euclid440; 11-07-2015 at 03:54 PM.

-

The Following 16 Users Say Thank You to Euclid440 For This Useful Post:

10Pups (02-03-2016), ejmolitor37 (02-12-2016), engine46 (12-23-2015), Geezer (11-10-2015), Hirlau (11-07-2015), JazzDoc (01-04-2018), jmercer (08-20-2016), joelkerr (03-10-2020), markbignosekelly (02-11-2016), MikeB52 (11-10-2015), MisterClean (12-24-2016), MisterMoo (02-11-2016), nipper (02-11-2016), Substance (05-10-2016), tinkersd (03-30-2017), WW243 (01-07-2016)

68Likes

68Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote