Results 1 to 10 of 17

-

01-16-2016, 04:18 PM #1

The famous Thuringian Stone Honing Machine

The famous Thuringian Stone Honing Machine

Some of you may have asked how the old hollow razor grinders honed their straights. The bigger razor companies produced hundreds of razors a day and also a single grinder could finish up to a dozen or even more if he used a hollow grinding machine or was very experienced and skillfull to do this by hand. So how did these grinders or companies hone their razors after they have been grinded. By Hand? Hundreds a day?

No!

I can only speak for the hollow grinders in Germany and don’t know, if there had been similar developments in other countries in the 19th or 20th century.

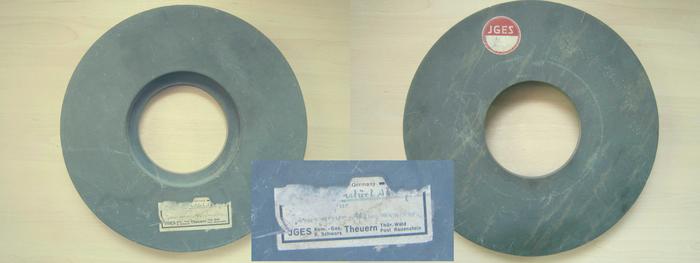

The first time I heard about this machine was, when I visited an old hollow grinder - while I was searching for thuringian whetstones maybe 5 or 6 years ago. Instead of benchstones he gave me two disks with a diameter of 9.5 inch and a thickness of nearly 1’’, that were visibly made of thuringian waterwhetstone.

When I asked – what have these disks been for? … he answered that they belonged to an old machine for honing razors, that, unfortunately, he had disposed several years before.

He also gave me some coarser man made disks of the same diameter

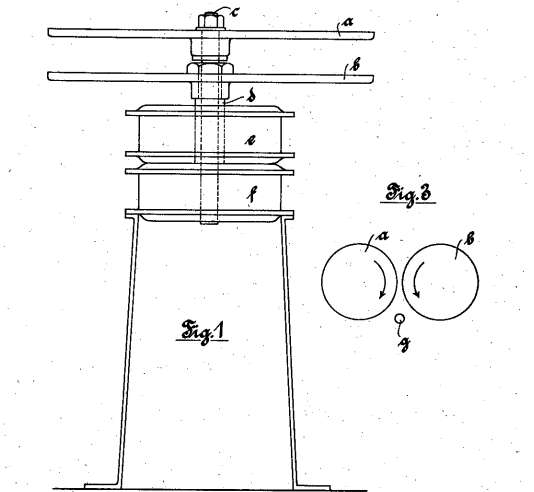

Than he explained the principle of the machine. The disks were mounted on two different shafts that moved in reverse directions, the disks oriented horizontally like plates. On the bottom of each shaft the coarse artificial disk for setting the bevel on a razor was mounted and above maybe with a distance of 10-15 cm the thuringian disks for finishing the straights. The razor was laid down flat on the turning disk for a few seconds, then moved slowly backwards until only the front part of the razor was on the disk and then switched by a turn off the reel to the other plate, to hone the other side of the razor. Having done this a few times, the razor could be honed to perfect endfinishing in a few minutes.

Well you may imagine that I was fascinated by this machine and I strongly wanted to figure out, how this machine looked like and how it was operated. The machine is also described in the famous german textbook “The straight razor”, which was published in 1939, describing the so-called Hamburg way of hollow grinding. But there is no figure or picture of the machine in the book.

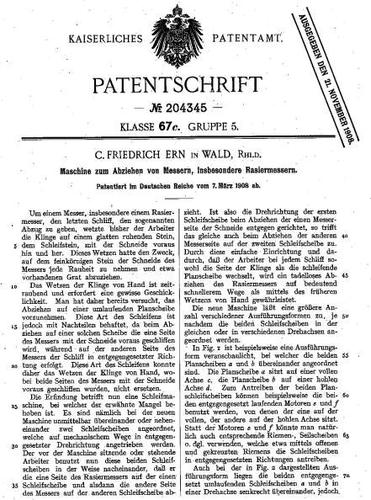

I looked for old advertisements, photographs and so one, but didn’t find anything concerning this machine. My investigations brought a first result when I found the original patent of this machine. The first patent was registered in 1908 by Carl Friedrich Ern, the famous Solingen razor grinder and developer of the double hollow grinding machine called “Hexe” (witch) that revolutionized the razor manufacturing in the early 20th century.

In this first patent two disks were arranged on top of each other, the first one driven by a hollow shaft in one direction, the second one above driven by a full shaft the moves in the hollow shaft in opposite direction. So by this solution the disc are both of the same material and quality and the razors had to be moved from the lower disk to the upper disk.

On a later stage, the solution with two shafts side by side and equipped each with two disks was established. The following scheme shows the principle:

The machine was build by the Solingen company Louis Perlmann, a company which was a main supplier for equipment to the hollow grinders, but also produced their own razors, brand names “Louper”, “Flamme” and “Golf”.

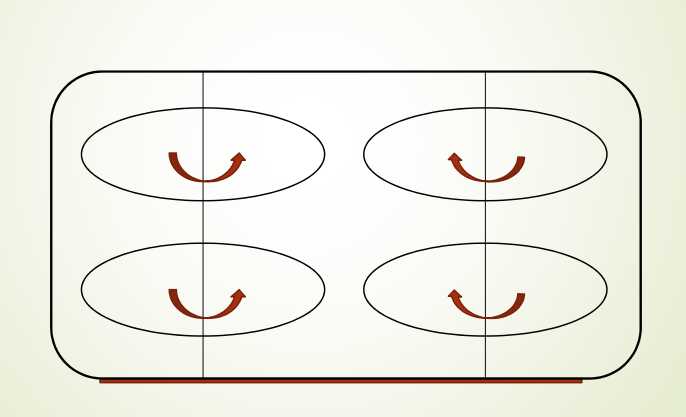

The grinders I spoke to, also explained me that there had been machines with three discs on each shaft, below a coarse artificial stone for bevel-setting, followed by a blue thuringian for the progression and on top a yellow-green thuringian for endfinshing.

Here are the three different disks. The blue one is an Escher (JGES) labelled disc and is produced at the last site of the Escher& Son company in Theuern.

Each of the discs made of thuringian whetstone have a weight of 2 – 2.5 kg!

It must have been a very difficult and hard work to cut these disks from the raw material in ancient times, without electrical machines. I have found a lot of broken pieces from discs at the old production sites.

… to be continued…

-

The Following 29 Users Say Thank You to hatzicho For This Useful Post:

Badgister (04-29-2020), criswilson10 (01-19-2016), eddy79 (01-19-2016), Euclid440 (01-16-2016), Frankenstein (01-17-2016), Geezer (01-17-2016), jfk742 (01-17-2016), karlej (01-22-2016), Kees (01-17-2016), Leatherstockiings (01-16-2016), mainaman (01-17-2016), MattCB (01-16-2016), MikeB52 (01-16-2016), nipper (01-17-2016), Phrank (01-17-2016), RezDog (01-16-2016), rodb (01-17-2016), rolodave (01-16-2016), RusenBG (04-28-2016), sharptonn (01-17-2016), Substance (01-17-2016), Tack (01-17-2016), Thug (01-17-2016), tintin (01-17-2016), Utopian (07-27-2017), Walterbowens (01-17-2016), Willisf (01-16-2016), Wolfpack34 (01-16-2016), WW243 (01-16-2016)

-

01-16-2016, 04:30 PM #2

Thank you for sharing this , Peter.

Glad you have the ability to go to places like this and explore and research all this.

Amazing how advanced they were "back in the day". This helps to solve the mystery of how they sharpened so many blades. Only 3 different wheels were used? Interesting!

Those sharpening wheels would be priceless today as is the information you are sharing today. It would be so cool if you could actually find a machine that was intact and use it again.

Great knowledge as always! Thank you again!

WillisIs it over there or over yonder?

-

01-16-2016, 04:33 PM #3Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,466

- Blog Entries

- 1

Thanked: 4207

Great topic and history.

.

.

I've toyed with the idea of making something similar but with lapping film ever since I started into this way of shaving actually. Look forward to more history and pics of those incredible stones!

A set of those would be so awesome to have. Congrats for your diligence in finding some.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

01-16-2016, 04:36 PM #4

-

01-16-2016, 05:15 PM #5Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

[QUOTE=hatzicho;1589902] The first patent was registered in 1908 by Carl Friedrich Ern, the famous Solingen razor grinder and developer of the double hollow grinding machine called “Hexe” (witch) that revolutionized the razor manufacturing in the early 20th century.[/FONT]

One must wonder where he got this idea for the hollowing machine from... Wolferts grinding machine was well before this one. http://straightrazorpalace.com/works...ne-1898-a.html[QUOTE]Last edited by Martin103; 01-16-2016 at 05:18 PM.

-

-

01-16-2016, 05:39 PM #6

[QUOTE=Martin103;1589914][QUOTE=hatzicho;1589902] The first patent was registered in 1908 by Carl Friedrich Ern, the famous Solingen razor grinder and developer of the double hollow grinding machine called “Hexe” (witch) that revolutionized the razor manufacturing in the early 20th century.[/FONT]

One must wonder where he got this idea for the hollowing machine from... Wolferts grinding machine was well before this one. http://straightrazorpalace.com/works...ne-1898-a.html

Interesting - I didn't know the Wolfert patent. Thanks for sharing.

But the Ern patent I described above from 1908 belong to the honing machine, not the grinding machine. The double grinding machine was developped by Ern in the year 1893, so long before he developped and patented the honing machine. It simply took some time from development until the Solingen razor companies really accepted! and used the machine. Carl Friedrich Ern was a great grinder and developper but also disputed among the other Solingen grinders for his new ideas and methods. Therefore I wrote .. in the early 20th...

Regards PeterLast edited by hatzicho; 01-16-2016 at 05:48 PM.

-

01-16-2016, 06:05 PM #7

Well over the years I spoke to a lot of old hollow grinders and found three machines. Two of them are still in usage by the grinders, a third one hasn’t been used for years and stands in an old shed among other machines. Unfortunately, none of the people I met was willing to sell me his machine, also not the one who don’t use it any more. But the two people that still work with the machine showed me how to use it. And I found some more disks, mainly well used and washed out. Also some smaller disks, used for different machines.

Finally, at the beginning of last year I made a call by another german grinder of a younger generation. I didn’t expect to hear from him –yeah I have such a machine, you can have it, I don’t need it any more…..

Surprisingly he said exactly these words! I couldn’t believe it!

I met him a few days after the call. Of course, the machine was not in best condition. It was stored outside in an old shed, but the shafts move and the disks were intact and not broken.

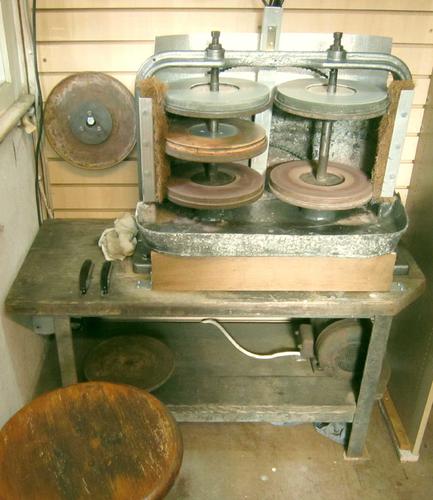

This was the first photo he sent me from the machine:

The big surprise was, it was a machine normally carrying 2x3 disks. Only one shaft was equipped with three disks though and it was not a blue thuringian, but another fine stone. First I thought it might have been a coticule, but it is too hard. So it should be a fine artificial stone, some kind of early ceramics. I have some old benchstones from this material too.

The artificial stones for bevel setting are really coarse. The thuringians are natural combination stones blue/ yellow-green:

I spent a lot of time to restore the machine, but want to keep as much as possible from the old parts. So I didn’t make a new pan for example, but kept the old one and sealed it with water glass and epoxy. I made a new water distributer to all the disks and fixed everything else as good as possible and give it a new paint. Fortunately the motor was still running, I only had to exchange the belt-drives.

Honing on the machine is not an easy thing and needs much experience. You have to be very carefully. Metal is removed very fast – a least with the coarse artificial stones. Also it is not easy to keep the razors really flat on the disks, while moving them backwards, especially for the upper disks, when you sit in front of the machine. And at least - it is a relatively whet experience. I have mounted new water deflectors on the sides but still the water is skidding in your face, while you are sitting in front of the machine.

But beside this I cannot describe the fun I have while using the machine!

… to be continued…

-

The Following 20 Users Say Thank You to hatzicho For This Useful Post:

Badgister (04-29-2020), criswilson10 (01-19-2016), cudarunner (01-18-2016), eddy79 (01-19-2016), Frankenstein (01-17-2016), JimmyHAD (01-16-2016), Leatherstockiings (01-16-2016), mainaman (01-17-2016), MattCB (01-16-2016), MikeB52 (01-17-2016), Phrank (01-17-2016), RusenBG (04-28-2016), sharptonn (01-17-2016), Steel (11-04-2018), Substance (01-17-2016), Tack (01-17-2016), Thug (01-17-2016), tintin (01-17-2016), Walterbowens (01-17-2016), Willisf (01-16-2016)

-

01-17-2016, 02:31 AM #8

thank you for sharing. this is fascinating!

-

01-17-2016, 02:36 AM #9

Extremely cool! Thank you for sharing this!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

01-17-2016, 03:13 AM #10

Agree with Tom, superb, thank-you for sharing this.

Can I send you some old wedges to turn into fine hollow ground blades?

72Likes

72Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote