Results 1 to 8 of 8

11Likes

11Likes

Thread: Failed restorations

-

02-10-2016, 03:35 PM #1Junior Member

- Join Date

- Nov 2015

- Posts

- 17

Thanked: 1 Failed restorations

Failed restorations

I know this is not a topic many of us want to talk about as I'm sure some may be painful or sad, but I think there is still lots that can be learned from them. I've been looking for info on wedges lately and can't find examples of rusted edges and why they should be avoided. Found lots of info on not buying them, advice about getting to clean metal.. Crumbling edges.. Etc. but no picture to see if I'm out of the game on this one or not.

if anyone is willing to share failed attempts and some words of wisdom or things to look for. Please do. I'm sure this will help others. Especially the new guys.

-

02-10-2016, 08:37 PM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

It is near impossible to tell from a wedge grind razor how much rust is too much, unless of course it is insane amounts. When doing restores, if there is an inkling of doubt about the bevel being able to hold an edge afterwards, it is the best place to start. Scrape the active rust off with a single edge blade and then go to the 1K and see is you can get to nice clean steel. You will need to look with a 30x or better loupe to see the pinholes in the steel, once you have gotten to the point of a nice clean bevel, you can dull it and start your restore. A wedge grind has a ton more steel than any other grind and can withstand sanding that would kill a full hollow. Full hollow and extra hollow blades cannot take much material removal with making the steel too thin to be workable, where as a wedge can be completely reground.

It's not what you know, it's who you take fishing!

-

02-10-2016, 08:49 PM #3

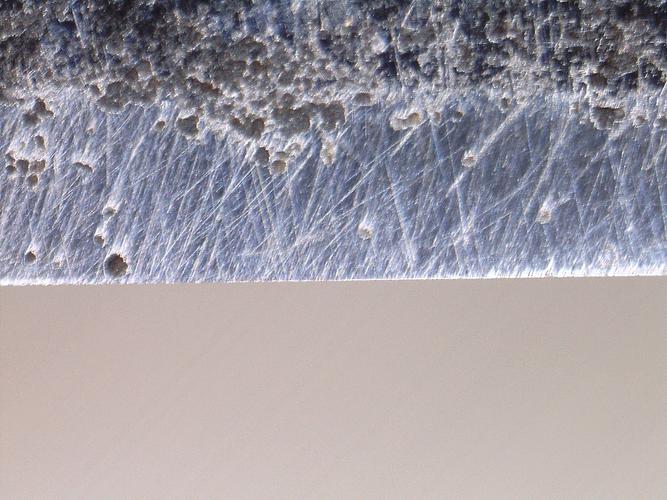

This is what pinholes look like under 300x magnification:

"Every normal man must be tempted at times to spit on his hands, hoist the black flag, and begin to slit throats." -H. L. Mencken

"Every normal man must be tempted at times to spit on his hands, hoist the black flag, and begin to slit throats." -H. L. Mencken

-

02-10-2016, 09:57 PM #4

Nice picture, thank you for sharing! I haven't tried a wedge yet that wasn't able to be saved, as mentioned above you have lots of steel to work with! When looking for restoration projects that are hollow ground blades it is sometimes a shot in the dark. Sometimes they can be saved and other times they end up in the always famous round file

-

02-10-2016, 10:28 PM #5Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Rez hit the nail on the head for your answer but I would add that if you don't have a proper grinder you may wear your fingers out before you get to the bottom of some pits. Even with a grinder there are points when you decide to stop if the razor is that badly pitted. It's always a gamble until you get at it and see what there. Restore failure can be a relative term. See this post http://straightrazorpalace.com/custo...ml#post1597159 It could be a failure because I didn't get all the pits out or it could be a victory because it shaves again and doesn't look that bad.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

02-10-2016, 11:54 PM #6Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

There are different measures on what is a fail for sure. I did over sand an extra hollow blade that got so thin and flexible it was useless as a razor, I have no idea what I may have done with it and certainly did not take the time to take pictures. I dropped a couple of razors while working on them. One is in the process of being shortened by 1/8", the other likely won't be a shaving razor again. I have put a few shavers back on the line that were less than perfect, but the continued to work for their designated purpose. Not all of my restores have been restored to "like new" many of them have been restored to serviceable.

It's not what you know, it's who you take fishing!

-

02-11-2016, 02:08 AM #7Junior Member

- Join Date

- Nov 2015

- Posts

- 17

Thanked: 1

Yeah I agree there are definitely different degree of failure. Maybe I just wanted to feel better about my own failures haha. Either way I think that there is still a lot of good experience to be learned from short coming and that's what I wanted to learn from all of you instead of having to learn each lesson individually.

-

02-11-2016, 02:14 AM #8Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

Some of my earlier work I have gone back over and fixed.

It's not what you know, it's who you take fishing!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote