Results 1 to 10 of 22

-

02-17-2016, 05:03 PM #1Junior Member

- Join Date

- Jul 2015

- Location

- North Carolina

- Posts

- 10

Thanked: 0 Advice on ivory tang restoration and scale selection

Advice on ivory tang restoration and scale selection

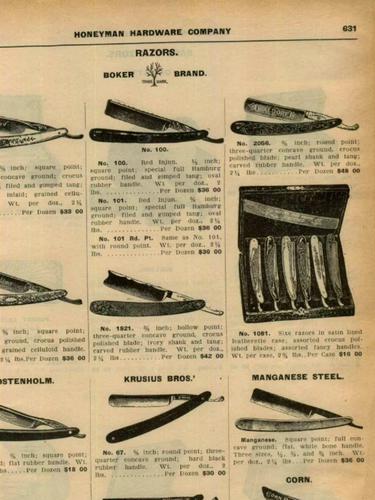

My current project is this old Boker with ivory tang. Pretty rough but I would love to make this work. I removed the scales it came with( nothing special and not original to the razor). The steel was rusted at the tang as you can see by the pitting. I want to make this a shaver. So...now do I paint the steel part of the tang, or use Ren wax? How do I keep it from rusting again? I would also love to find a way to restore the logo if anyone has any suggestions. That is the the hard part. Then what scales to put on it. I'm considering horn or ebony.

My current project is this old Boker with ivory tang. Pretty rough but I would love to make this work. I removed the scales it came with( nothing special and not original to the razor). The steel was rusted at the tang as you can see by the pitting. I want to make this a shaver. So...now do I paint the steel part of the tang, or use Ren wax? How do I keep it from rusting again? I would also love to find a way to restore the logo if anyone has any suggestions. That is the the hard part. Then what scales to put on it. I'm considering horn or ebony.

-

02-17-2016, 05:09 PM #2< Banned User >

- Join Date

- Dec 2013

- Location

- Perth, Western Australia

- Posts

- 318

Thanked: 44

What makes you think its ivory? If you were to clean off the old rust and then coat it with Renaissance wax before re-assmbling it'd be good for decades. I'm not sure why these came out in two tone scales, but I've seen enough of them to know they're probably not a rescale. Here's one I have with scales that actually match. You see the scales for sale quite often in different states of repair on different razors

.

.

Last edited by puketui41; 02-17-2016 at 05:33 PM.

-

02-17-2016, 06:40 PM #3At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

Clean the rust, then use a really good epoxy to re-attach the tang cover, this will seal the area for more years then you need to worry about it

an added bonus will be to strengthen the "Ivory" also

an added bonus will be to strengthen the "Ivory" also

I have done quite a few of these now but here is the very first one also a Boker take a look it might give you some ideas

take a look it might give you some ideas

http://straightrazorpalace.com/custo...t-acrylic.html

-

02-17-2016, 08:22 PM #4Junior Member

- Join Date

- Jul 2015

- Location

- North Carolina

- Posts

- 10

Thanked: 0

-

02-17-2016, 08:46 PM #5Junior Member

- Join Date

- Jul 2015

- Location

- North Carolina

- Posts

- 10

Thanked: 0

Super nice razor gssixgun!

Last edited by Parker76; 02-17-2016 at 08:50 PM.

-

02-18-2016, 02:41 AM #6< Banned User >

- Join Date

- Dec 2013

- Location

- Perth, Western Australia

- Posts

- 318

Thanked: 44

You could possibly take a photo of the complete lettering to an engraver and get them to put a shallow engraving on it, then blend up some matching paint, fill the engraving and wipe off the excess

-

02-18-2016, 03:19 AM #7

-

02-19-2016, 01:28 PM #8

You will find that standard pin stock at 1/16" is too big for the two retaining pins - cut about 1.5" and put it in a drill and use some wet 7 dry paper to take it down to the required size.

My service is good, fast and cheap. Select any two and discount the third.

-

02-19-2016, 07:46 PM #9Junior Member

- Join Date

- Jul 2015

- Location

- North Carolina

- Posts

- 10

Thanked: 0

Great advice ukrob!

-

02-19-2016, 07:51 PM #10Junior Member

- Join Date

- Jul 2015

- Location

- North Carolina

- Posts

- 10

Thanked: 0 Well...disappointed is an understatement.

Well...disappointed is an understatement.

So I was almost done polishing and it was looking good.

And then this happened.

And then this happened.

So. Crap.

So. Crap.

29Likes

29Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote