Results 1 to 10 of 14

Thread: What rake for my 4" wheels?

-

03-12-2016, 01:02 AM #1

What rake for my 4" wheels?

What rake for my 4" wheels?

I received eight 4" sewn wheels from Caswell and was wondering if a standard rake is necessary for them or not?

They seem small for the size of some of the rakes I have seen. Can anything else be used or made in it's place?My son is a Drill Instructor in the United States Marine Corps at Parris Island, SC

Mike

-

03-12-2016, 01:19 AM #2Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

I have never used a rake on any of mine. They are all dedicated to the first compound I put on them. Then again maybe I just don't know any better :<0)

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

03-12-2016, 01:24 AM #3

Wire brush, anyone will do. Grill brush if it gets matted. Probably wont happen this year, unless you buff 50 plus razors. Dont need nothing longer than the first sewn line.

Your only as good as your last hone job.

-

03-12-2016, 01:39 AM #4Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

The Castell rake works just fine, it does look large for the wheels, but you want to be able to hold on to it in case it grabs.

The first few times you rake, you will be covered in fibers, so wear a mask. A vacuum hose duct taped to the bench at the bottom of the wheel, will suck up a lot of lint. I also use a strong fan blowing across the buffer and away from me, out the garage door.

After a few rakings and loading, the amount of fibers will greatly reduce.

Take a pair of sharp scissors and trim all the loose threads from the wheel so you have an even nape. Turn the wheel by hand when trimming. Any long threads on the wheel, will keep it from loading smoothly and you will feel it on the razor.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

ProudMarineDad (03-12-2016)

-

03-12-2016, 01:45 AM #5

Euclid, is this the same thing? I didn't find much with a Google search for 'Castell' so I ordered this one.Buff Rake for Cleaning Dry Buffing Compound Remove Dress Wheel Surface Edge | eBay

Last edited by ProudMarineDad; 03-12-2016 at 01:54 AM.

My son is a Drill Instructor in the United States Marine Corps at Parris Island, SC

Mike

-

03-12-2016, 01:58 AM #6

Well as some know I really prefer the High Tech on most anything I do so while I did purchase a commercially manufactured 'rake' when I built my buffer I have never used it.

I went All Out! And used the best quality tool I could find! It's done well for these past few years and while it's worn, It's still got years of life left in it.

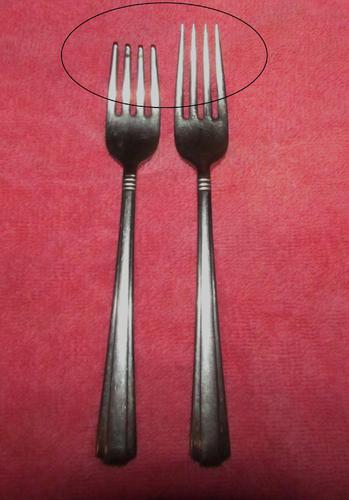

I do have a back up. You can see the 'Rake' on the left and also see what my original 'Rake' looked like on the right .

Did I say 'High Tech'??

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

spazola (03-12-2016)

-

03-12-2016, 02:18 AM #7Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Looks like the same one, about 12 inches long and about 3 wide.

Here’s the link.

They re-made the website a couple years ago and it is very difficult to navigate. It has a large header that eats up a third of the page.

There are small page numbers at the bottom of the page that opens the rest of the site, but it is easy to miss and the links open very slowly, takes about 30 seconds or so.

It is a frustrating website, but is a good company with great products.

-

03-12-2016, 02:29 AM #8

I have used that take for about 50 years. I also have used a wire brushes and a wood rasp. All work and I try to keep the buff surface flat to assure that I have control of the edges. I can better control my placement that way.

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

03-12-2016, 02:31 PM #9

CasWell plating same company you purchased the wheels from.

Your only as good as your last hone job.

-

03-12-2016, 11:12 PM #10

A well made new wheel like Caswell sells does not need to be raked unless you want to be covered in a mess of cotton fibers IMHO. You should be able to evenly load a new wheel with greaseless if you are experienced. If not then Glu-Tite is your friend will help load a wheel but don't hog it on just a thin layer that you can see through is enough. Once the greaseless has adhered to the wheel it should be in an even coat. I tried to take a couple of pictures as a reference. The first in an even coated wheel that I've used and loaded a few times. The second kind of looks like a broken lava field and it's time to rake this wheel and apply fresh greaseless. Stay towards the bottom of the wheel and hang onto it tight as you introduce it to the periphery of the wheel. It may try and rip it from your hands. Respirator and eye protection are mandatory in my book.

Once I think my wheels are not cutting well I reload them. I don't wait until all the compound is worn off the wheel. You'll be able to see when it is not cutting efficiently. It will look more like it is polishing the metal than cutting. Kind of like sandpaper. The fresh new stuff cuts the best. The grit on the wheels wears like sand paper. Someone once said use sandpaper like someone else is paying for it.

Do take the time to mark your wheels with rotation direction and grit size. I know some think the direction makes no difference but the greaseless lays down in one direction and if you reverse it the first time you touch steel to the wheel you'll have compound breaking off the wheel and flying everywhere. It will also cut more even with no deep cuts.

I could drone on but I'll leave it here.

Last edited by karlej; 03-13-2016 at 12:38 AM.

18Likes

18Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote