Results 1 to 10 of 10

10Likes

10Likes

Thread: Wood scale question

-

03-20-2016, 02:45 PM #1

Wood scale question

Wood scale question

What types of wood do not work well and what types do? What type of treatment does the wood need before, during and after shaping? I have some red cedar that I think would look really good on an Imperial that I am restoring.

Any and all advice is most appreciated.

Thank you,

John

-

03-20-2016, 06:31 PM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,194

- Blog Entries

- 1

Thanked: 13250

In General

Hardwoods = Good

Softwoods = Bad

With the addition of the very thin .030 G10 sheets you can now do just about any wood you want to by using a G10 backing..

If I were going to be using Cedar,,, I "wood" do a G10 backer and use a hard coat sealer like maybe a CA or poured Epxoy finish..Last edited by gssixgun; 03-20-2016 at 06:34 PM.

-

The Following User Says Thank You to gssixgun For This Useful Post:

jwy77 (03-20-2016)

-

03-20-2016, 07:55 PM #3Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

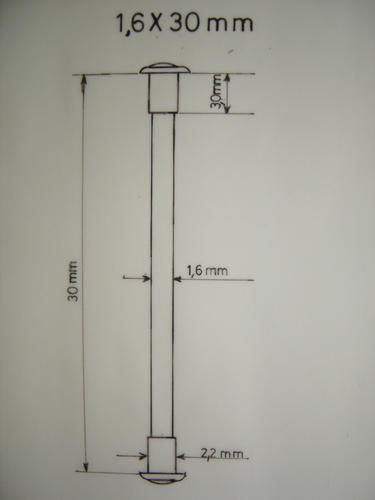

If you have some soft wood with really crazy and small grain pattern you can use eyelets so that the load of the tension is carried by the barrel of the eyelet and not the wood. Essentially with soft wood the tension on the collars is too much and they sink into the wood and split the scales. It is quite a bit of monkeying around to get beyond that. That coupled with soft woods tend to have wider grain and it is hard to find any that are cool at a size as small as a scale. The other option is some of this style of collar, which is similar but stronger than an eyelet.

It's not what you know, it's who you take fishing!

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

jwy77 (03-20-2016)

-

03-20-2016, 08:52 PM #4

Thank you for the info. This is a pretty old piece of red cedar that a finish carpenter that is now retired gave me. He had mentioned soaking it in Linseed oil after the rough cut has been made would make it a little more forgiving to work with. I have time. I just need to learn more.

-

03-22-2016, 06:24 PM #5

If it is old cedar and very dry then an oil soak would be a good idea. Linseed oil will work as will tung oil. Keep wiping it with the oil until it stops absorbing it - which may mean several days of applying coats to it.

Once it is all oiled up, add a sealer to the wood like polyurethane, varnish, or shellac. You will want that wood to be sealed because cedar rosin plus a little water plus metal will equal rusted bladed.

You will probably need either a backer for the cedar and/or some larger than normal washers because the pin is going to sink into the cedar and tear out with the regular small washers. Try it first on a scrap piece of cedar.Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

03-24-2016, 08:34 PM #6

Last edited by jwy77; 03-24-2016 at 08:39 PM.

-

03-24-2016, 08:59 PM #7

You are fortunate to have extra to work with, because often scales do not go as planned...

I would follow the advice above and get some of the thin g10 backing, it will be more work but your finished product will be better

Enjoy the process, and post some pictures!

-

The Following User Says Thank You to Ernie1980 For This Useful Post:

jwy77 (03-25-2016)

-

03-25-2016, 06:46 AM #8

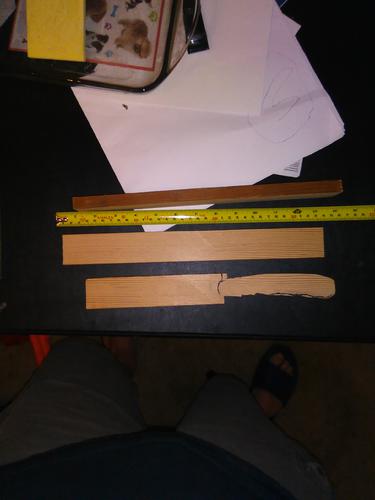

This is the red cedar blank

I have done nothing yet.

-

04-03-2016, 12:23 AM #9

Just looking for adviceLast edited by jwy77; 04-03-2016 at 12:37 AM.

-

04-06-2016, 02:51 AM #10

Problem with linseed oil is it does not cure. It simply soaks into the wood and stays oily. If you want a finish that cures but keeps that oiled look you can use linspeed oil. Tried and True make a varnish oil that is polymerized Linseed oil and varnish resin. I use it on vintage rifle stocks. It will cure and give you a nice satin sheen and offers more protection than linseed oil.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote