Results 1 to 10 of 10

33Likes

33Likes

Thread: Yet another way to make a wedge

-

04-17-2016, 09:11 PM #1

Yet another way to make a wedge

Yet another way to make a wedge

i've been working on this method for a while and finally found a way that works. this one is made with pewter but i think lead would work the same way

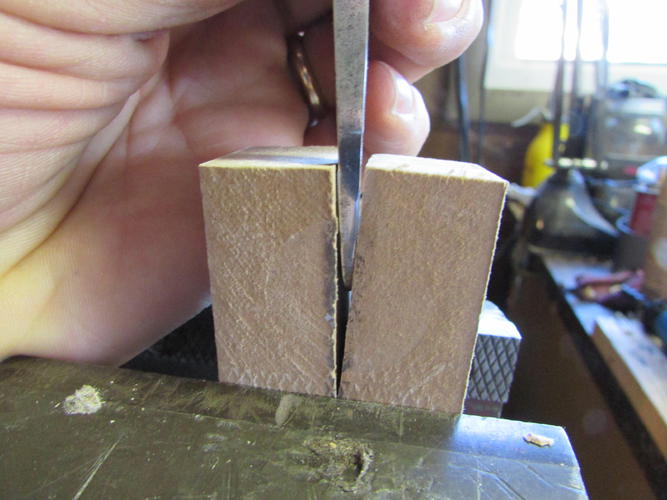

i first clamped two pieces of wood in my vise like this (make sure the bottoms touch or your metal will run out the bottom)

make the taper match that of your razor, then tighten the vise and attach c-clamp to act as a seal,like this...

pour in melted pewter and let cool.

and voila, a perfect wedge

all that's left is to cut and fit the wedge(plenty of other articles on that)

-

The Following 11 Users Say Thank You to tintin For This Useful Post:

32t (04-18-2016), aaron1234 (04-17-2016), Chevhead (04-17-2016), criswilson10 (04-20-2016), dinnermint (04-26-2016), engine46 (05-28-2019), Geezer (04-18-2016), Hirlau (04-18-2016), sharptonn (04-18-2016), spazola (04-18-2016), ultrasoundguy2003 (04-18-2016)

-

04-17-2016, 11:41 PM #2

Pretty cool technique on making wedges!

Is it over there or over yonder?

Is it over there or over yonder?

-

The Following User Says Thank You to Willisf For This Useful Post:

tintin (04-18-2016)

-

04-18-2016, 01:15 AM #3Member

- Join Date

- Feb 2016

- Location

- North Carolina USA

- Posts

- 69

Thanked: 9

Great idea

I'm going to have to try thatHave a great day!

Craig

-

04-18-2016, 01:51 AM #4

I just flatten a pure lead ball (.535" for a flintlock rifle I used to own) with a flattened and polished hammer and steel benchblock. When it gets down to around 1/10" thick, I forge in a taper and match it to the dimensions required. I true it up using wet sandpaper (to contain the dust) over the bench block to provide a flat surface then rough cut to fit with flush cut snips. Final shaping is done with a Swiss file after pinning. Whole process takes under 10 minutes with no lead fumes or hot metal.

"Every normal man must be tempted at times to spit on his hands, hoist the black flag, and begin to slit throats." -H. L. Mencken

-

04-18-2016, 11:09 AM #5

You can never have too many wedge making threads.

My service is good, fast and cheap. Select any two and discount the third.

-

04-18-2016, 12:11 PM #6

I did something very similar a few years ago. It certainly does work but was to much work. http://straightrazorpalace.com/works...-way-i-do.html

-

04-18-2016, 05:25 PM #7

yep, tried the hammer method too. didn't like trying to get the angle right. thought this would eliminate the guess work. like the title says"yet another way to make a wedge".

-

04-18-2016, 08:38 PM #8

-

04-18-2016, 09:17 PM #9Senior Member

- Join Date

- Oct 2010

- Posts

- 26,211

Thanked: 8626

Pretty sharp!

I hope this does not render my Wedge-O-Mat obsolete! Nothing more to say........

Nothing more to say........

-

The Following User Says Thank You to sharptonn For This Useful Post:

tintin (04-19-2016)

-

04-18-2016, 10:46 PM #10

Pretty nice!

Ed

-

The Following User Says Thank You to Chevhead For This Useful Post:

tintin (04-19-2016)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote