Results 1 to 10 of 17

Thread: Trouble with Horn for scales

-

05-27-2016, 12:24 AM #1

Trouble with Horn for scales

Trouble with Horn for scales

Hi everyone

I might already asked this question or a relative one here. I've a French blade with a fancy spine about 7/8 ( but it will lose some because the edge had some rust but not a big deal). Its actual scales are made by plastic but the size doesn't fit. So as have some black horn, I started to make new scales for this one.

Before go further, is like to have some advice from you guys. These horns are about 5 mm thick. And I need to absolutely make them finer, lose some thicknes. I tried some hand sanding before with wood for an other blade but it's really trying, it takes to much time and not the perfect result. I also tried with a electronic sander. I had similar issues but better than hand sanding.

Well with electric sander the problem is; actually it is made for send floor. But I'm using it, with turning down side to up and put the horn or wood on. But as it's so powerful I can't control/ keep the material stable on it every time, last time the wood was not perfectly plane. So tomorrow I went to start on this job but still not sure how to take these horns to make them finer?

I'm looking for a fast but good result.

As always any advice will be appreciated ...

-

05-27-2016, 01:43 AM #2Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yea, don’t do that…

Take a look at this thread. Hand Sanding Horn

Post 6 and the link to Karlej’s tutorial with very good photos and step by step instruction.

There are also some good templates of Sheffield scales somewhere, google Razor Scale, I will take a look for you also.

-

05-27-2016, 02:32 AM #3Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

You might want to take a look at the

Welcome to the Workshop

and Making Scales Step by Step tutorial from the library.

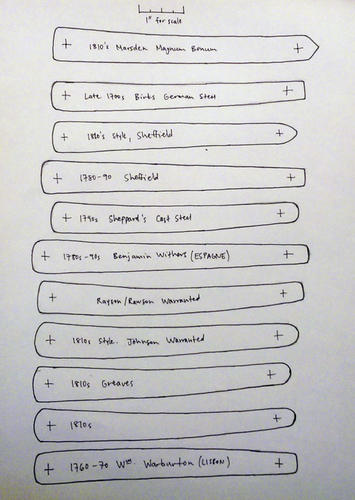

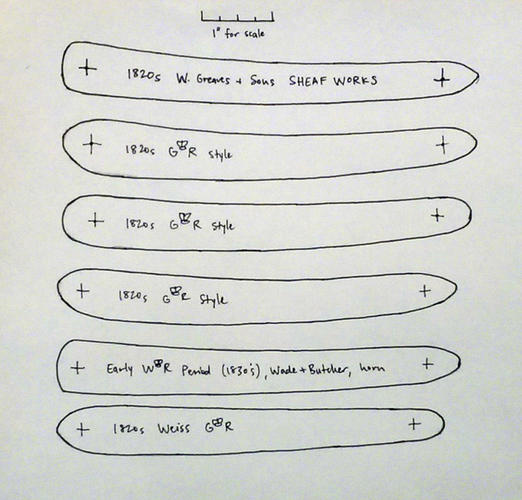

Here are a couple Tracings of old scales.

-

-

05-27-2016, 01:59 PM #4

thanks for these but i've already my exemples. just the thing my horn blocks are too thick, about 5 mm. i need to reduce them to 3.5 mm max. that's my problem.

-

05-27-2016, 03:21 PM #5

Choose a friendly luthier nearby if you do not have a thickness sanding machine, buy a 6-pack of good beer, chill them and go there at about 0600 PM to have a word with him. You'll be amazed how much you and him will enjoy talking about razors, musical instruments and handcrafting while drinking a late afternoon/early night beer while he adjusts the thickness of your scales in a blink. Go make a friend and introduce one more pal on the brotherhood.

"Excuse me, Sir, do you hame a moment to talk about classic things?". With a 6-pack in hands at 0600 pm, must be easy.

-

The Following User Says Thank You to Matheus For This Useful Post:

Oustoura (05-27-2016)

-

05-27-2016, 03:44 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

You can reduce the size and thickness quickly with a scraper and profile at the same time, as Karl shows in his tutorial.

Or with a sharp hand plane and a simple jig made from set of U shaped stops, made from paint stir sticks or a couple popsicle sticks glued on top of each other (depending on the thickness you are shooting for) and glued to a flat board, MDF works well as a substrate.

Just cut your horn into 1 inch wide slabs and plane them flat and to thickness. Do not nails or screws, if you hit them with the blade you will chip it. Wood glue is very strong for shear strength.

The stops will also act as a thickness gauge runners if you space them wider than the blade but not wider than the plane, allow for the amount of blade extending past the plane sole/face… You can shim the horn work piece between the runners or double faces tape them down.

.

Or just double stick tape the horn to a flat board and free hand plane it. Mark the thickness on the side of the horn clearly with a marking gauge or a sharpie and piece of wood or another scale flat on a work surface and used as a depth gauge.

If you use a compass or marking, gauge high-lite the mark with a colored sharpie and do not try to plane to final thickness. Get close and do your final thickening and shaping with a scraper and or sandpaper.

Horn is very soft and will plane easily and smoothly with a sharp plane blade.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Matheus (05-27-2016)

-

05-27-2016, 06:29 PM #7

jig with horn i don't think it's going to work. but i did it. i pasted the horn to a wood block and sanded it on a electrical sander. it took 2 hours + one and half hour cleaning (i'm so tired). now i just need to finish it.

-

05-27-2016, 07:50 PM #8Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,444

Thanked: 4828

You may want to consider attaching the blanks to a larger block of wood to allow you to hold and control it better while using an electric sander, double sided tape works well for this.

It's not what you know, it's who you take fishing!

-

05-27-2016, 08:44 PM #9

-

05-27-2016, 11:11 PM #10

It's not directly related with this post but it is a part of it.

As I've breathe problem and I use a medicament for it. The dust of horn kills me every time. I'm using some simple masks to protect myself but they don't work enough. Do you guys use any of a tool to protection from dust while working? What kind of a mask do you use?

23Likes

23Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote