Results 1 to 10 of 18

Thread: How to preserve blade etching

Hybrid View

-

06-03-2016, 01:16 PM #1Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,049

Thanked: 636

Etching looks pretty strong. I would work slow and try to avoid most of the blade etch. You should be OK on the shank. Do hand sanding so you have more control of metal removal. Good luck.

-

06-03-2016, 01:21 PM #2I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

If it were mine I'd get rid of any active rust and leave those beautiful age marks. Just me though.

Burls, Girls, and all things that Swirl....

-

06-03-2016, 01:33 PM #3Junior Member

- Join Date

- Nov 2015

- Posts

- 13

Thanked: 0

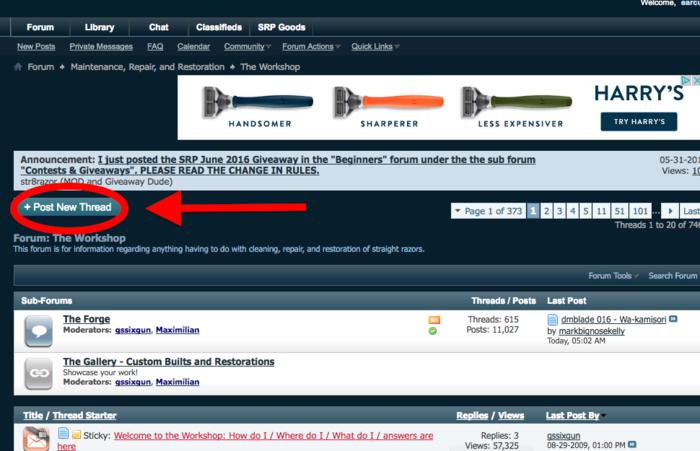

New to site how do I post a question or start a thread about razor restoration . Thanks Immy

-

06-03-2016, 02:12 PM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,458

Thanked: 4830

That looks like a good candidate for steel wool and WD-40. Finish it with mothers polish and all should be well.

It's not what you know, it's who you take fishing!

-

06-03-2016, 02:52 PM #5Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Saving an etch is delicate work, yours looks pretty deep though.

Lapping film works exceptionally well. For the blade start with 1k or higher with a stiff backer. Small pieces of wet & dry or film and a pencil on the tip of the eraser works well to sand around the etch, take your time.

Micro Mesh sanding pads and paper work well for cleaning up around the etch when used carefully, but use lapping film over the etch for maximum performance.

I buy my film from Thor Labs, but you can buy single sheets from some woodworking and carving supplies. Diamond lapping film is 10 times the cost, but do not produce 10 times the performance, Silicone and Aluminum Oxides

Here is an excellent post by Geezer on darkening bluing and high grit sanding, (Revealing Etchings). The trick to cold bluing is scrupulously clean surface and a bit of heat from a hair dryer or heat gun.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Whizbang (06-03-2016)

-

06-03-2016, 03:26 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

000 and 0000 steel wool works well for clean up as said. Start with WD40 then dry the razor and use the steel wool dry, with liquid Chrome Oxide, Diamond Paste or Liquid or a good metal polish.

Take a couple of wooden stir stick glue them together with CA glue, to double the thickness and clip the end square with a pair of side cutters. Clipping a single stick works well for cleaning between the scales with steel wool or a WD40 soaked paper towel, I like the Blue Shop Towels for cleaning razors, buy them by the case at Sam’s and Costco.

Wrap the tip with steel wool to get into tight spots, the shoulders of stabilizers and the tang near the pivot pin.

The stamping on the tang are generally deeper and you can use Wet & Dry in place of film to clean and polish the tangs. Cold blue works great to make stamps pop.

-

-

06-03-2016, 08:25 PM #7

-

06-03-2016, 11:30 PM #8

-

06-04-2016, 03:32 AM #9Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

You always will have better and quicker results cross direction sanding, unless you are laying down a satin type directional finish. Because you lay down a stria pattern then remove it cross directionally, then lay down another and remove it.

I hand sand 10 – 20 strokes in one direction, then sand 90 degrees to the stria you just laid down, when you can. Circles will leave circular scratches that are hard to remove, and I feel I have better control directionally.

Once you remove all you staining, rust or pitting, then you want to lay an even stria pattern that will be removed by the next grit. You can feel when the paper stops cutting, replace it. Paper is cheap.

Often folks think a shiny 1k finish is stria free, but look at it at 100 or 400X and you will see the scratches, even high grit polish leaves stria.

-

06-13-2016, 10:58 PM #10

Two questions:

1. How do you address the issue of the difference in appearance between the area you have covered in some fashion to preserve the etching...and the rest of the blade that now has a much "newer", cleaned up appearance?

2. Does steel wool just clean or would it eat into the etching? I suppose I could do an experiment, but I am hoping someone may have the answer.Last edited by Whizbang; 06-13-2016 at 11:00 PM.

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote