Results 1 to 9 of 9

36Likes

36Likes

Thread: Friodur MOP re-scaled & inlay transfer

Threaded View

-

07-12-2016, 05:58 AM #1

Friodur MOP re-scaled & inlay transfer

Friodur MOP re-scaled & inlay transfer

Thought I would share a bit of a "how to" or "how I did" for this project

This project was an original INOX Friodur with the front scale cracking at the pivot, s

o the request was made to re-scale it with a MOP option with the inlays transferred but recessed flush rather than glued externally to the new scales

The new materials used were:

Scales: OndaCrylic Faux MOP from Masecraft

Wedge: G10

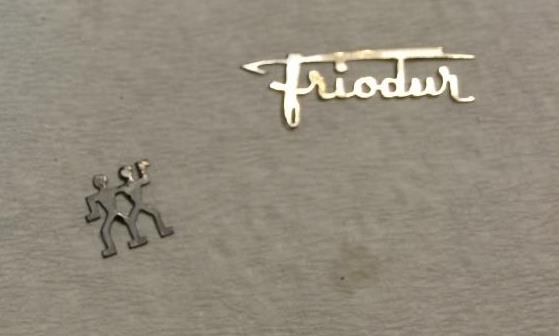

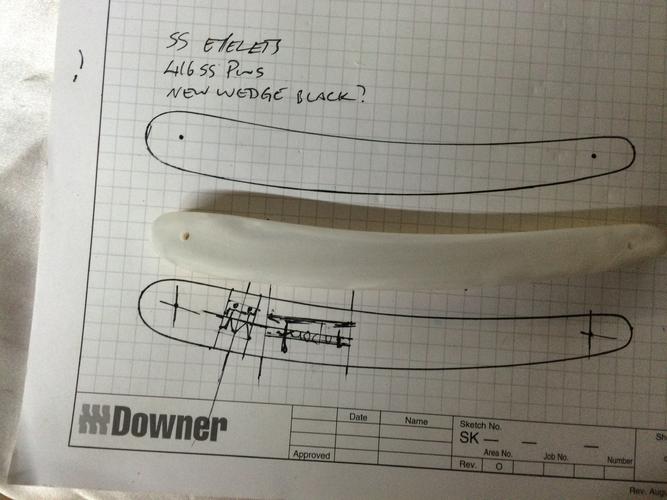

Washers: Brass Rhodium-Plated 3/16" Eyelet

Pins: 1/16” - 416 Stainless steel

Thrust washers: Original brass or bronze material reused

Glue: Tarzan Grip C.A. glue to hold the inlays in place

I forgot to take a before pic but onto the job at hand,

So started by removing the Blade by drilling out the Pivot pins first & reclaimed the original thrust washers,

the tang & pivot area were surprisingly very clean with just a wipe required.

removed the Wedge pin to discover the wedge partially glued to the front scale, which chipped when trying to remove it, so it wasn’t getting reused.

Then polished the inlays in the scale with some Autosol & finished with a clean cloth.

Once polished up & stripped down I used acetone in a small brush to coat the inlay area on the scale until they released.

This was a lot quicker than expected with minimal mess.

Gave the inlays a clean with some more Acetone on a smooth cloth & put a side ready for use.

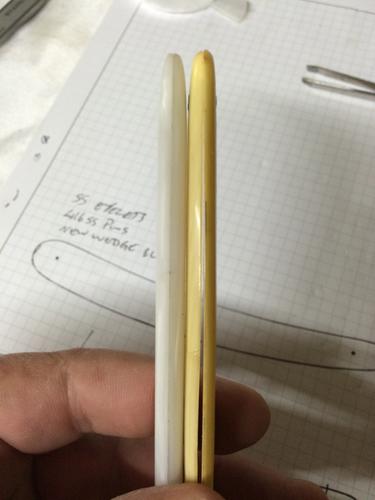

Used the original scales as a template for the shape & profile of the new scales, which were machine & hand sanded to a wet 5000 grit finish

Used an off cut to test some glues & solvents on the OndoCrylic with some great results

The inlays are only 7thou” thick & rather delicate so minimized playing with them were possible.

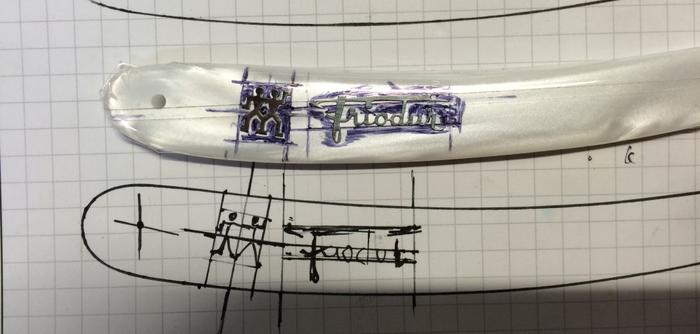

I used clear tape over the new scales & marked out the inlay positions & shapes, to match the originals with an Artline pen, once marked out I used a small engraving burr on the Dremel to remove the scale material deep enough for the inlays to sit under the scale level.

Once happy with the depth & area removed & removed the tape cleaned the new scale & inlays with acetone and left to dry

Stuck the inlays to some thin clear tape, filled the voids in the scales with CA glue & then taped the inlays in position in the glue, flipped the scale over to on a flat base with a weight on top overnight until cured.

With waiting for the glue to dry I started making a new wedge from the MOP material but I didn’t like the look of the white on white so made a new one from Black G10 to contrast the white MOP scales.

Once cured I then sanded the excess dry glue off and refinished the new scale to 5000 grit and hand polished with Ren Wax

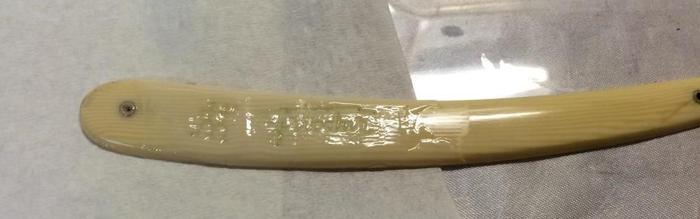

Now for some reason the glue produced some tiny bubbled during curing & these can be seen around the inlay, not sure what has happened here as I have never had it happen before with the same glue, was ready to re-dip in acetone & melt the glue to start again, but the owner was ok with them, so it was on with the re-assembly,

All standard stuff except I used eyelet washers & 416ss pins to match the inlays, as my nickel silver pin stock has a brassy look to it that I didn’t want for this.

There was no glue etc used in the assembly of the razor so it can the stripped down fully if ever required again.

Thanks for looking & hope this helps someone else along the way.

On a side note:

I found the OndaCrylic White MOP to be very easy to shape & finish using hand tools. It seems to be a very stable & was non-reactive to acetone and similar cleaners unlike the original celluloid scales & some other acrylics & polyesters. The material hand polished with Renaissance Wax only and I think it has come up well as it with a very nice deep look to the MOP I am definitely very happy with the OndaCrylic for scale making.

thanks for looking hope this helps someone else along the line.Last edited by Substance; 07-12-2016 at 06:05 AM.

Saved,

to shave another day.

-

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote