Results 51 to 60 of 80

Thread: The Harbor Freight Debate.

-

10-17-2016, 01:21 PM #51Senior Member

- Join Date

- Aug 2014

- Location

- East Central Illinois

- Posts

- 782

Thanked: 101

Behringer is made in China in their own factory & town. Uli Behringer is German & the headquarters are there. The quality of the Digital mixing board is top notch. I agree that some of their other products is junk but look at the quality of Peavey equipment in the early 70's. Pure junk. I have a lot of later Peavey sound equipment that is great and if at all possible buy USA made products. I don't think Peavey makes any products in the US anymore. If so just a few very high end things.

David Huffman

-

10-17-2016, 01:39 PM #52Glock27

- Join Date

- May 2016

- Location

- Michigan

- Posts

- 316

Thanked: 18

Not bought much from Harbor Freight (HF), but what I have bought has not been too bad, yet I don't use them with the frequency that would lead to problems. Guess it depends upon how much you are going to use the tool. If I know I will be using it a lot I will not buy from HF.

-

10-19-2016, 02:55 AM #53

Ok, I must admit. Today I stopped in HF and did buy a 'non consumable' item. I needed a 1" auger drill bit to drill thru a 12" laminate joist. Low and behold, they had a 3 pack of 18" auger bits (1/2", 3/4" and 1").....all for $19.99. I figured, even if they only lasted for a hole, it would be worth it (in which the 1" ate thru the lam like butter!) Worth the $20, IMO.

-

The Following User Says Thank You to AcesandEights For This Useful Post:

Glock27 (07-31-2017)

-

10-20-2016, 12:43 AM #54

-

10-20-2016, 01:36 AM #55

I buy in-expensive stuff at times....something that may only be used on rare occasions, why spend top $ on them? Other things such as hand tools, I tend to go middle of the road, like Craftsman. Why buy a high dollar Snap-On tool that is guaranteed for life, instead of a middle priced brand with the same guarantee?

-

10-20-2016, 02:05 AM #56

I was there tonight,, bought a large magnet, wire brushes, thread lock (blue) & got a free flashlight.

-

10-20-2016, 04:14 AM #57Senior Member

- Join Date

- Feb 2016

- Location

- pennsylvania

- Posts

- 302

Thanked: 66

i have purchased a scroll saw and two belt sanders from HF (4x36 and 1x30) to help make razor scales and so far they all work great. no complaints. but i also only use them on weekends so they dont get a lot of steady use. i know they are not best quality but i didnt want to commit too much $$ to early if i didnt stick with it. so far no regrets.

-

The Following User Says Thank You to sloanwinters For This Useful Post:

Glock27 (07-31-2017)

-

10-23-2016, 12:12 AM #58

A product I bought at HF, though I had all but forgotten about it after learning my lesson, was wet & dry sand paper. I don't recall the brand name (if any), but it was in a yellow and black "cardboard/cardstock envelope-style" package.

The verdict: Do Not Buy!!!

My experience: strapped for cash, and chomping at the bit to start restoring razors, I got a pack of 220 grit W&D meant for use on metal. Don't remember the price . It was in sheets of... 6x8" (roughly? You know the size). I cut off strips, as needed, to do hand sanding on the beaters (SRs) I got for cheap. I periodically rub the side of the blade where I've been sanding, with a clean fingertip, to both: reduce the risk of clogging the sandpaper, as well as to check how much metal is being removed during sanding. The W&D paper from HF can be described as having "rapidly diminishing returns"! The adhesive used is very thin, with little hold. The paper used is very thick, and does not lend itself well to wrapping around small, rounded backing materials/holders like what is common for us in this hobby.

. It was in sheets of... 6x8" (roughly? You know the size). I cut off strips, as needed, to do hand sanding on the beaters (SRs) I got for cheap. I periodically rub the side of the blade where I've been sanding, with a clean fingertip, to both: reduce the risk of clogging the sandpaper, as well as to check how much metal is being removed during sanding. The W&D paper from HF can be described as having "rapidly diminishing returns"! The adhesive used is very thin, with little hold. The paper used is very thick, and does not lend itself well to wrapping around small, rounded backing materials/holders like what is common for us in this hobby.

What you should use instead: 3M brand sandpaper!

I bought a similar pack of 3M "Ultra" sandpaper, in 320 grit to use on a granite tile as a lapping stone. I started using an extra sheet of this stuff like I had used the HF sandpaper. It was a night and day difference! Seriously. Despite being a slightly finer grit, the 3M removed more material in less time. That in itself astonished the heck out of me! What irritated me (at the HF stuff) was the fact that a strip of the 3M sandpaper lasted at least 5 times longer than the cheap crap. Maybe even 10 times longer!

There may be at least some room for debate when it comes to 3M tape. But trust me when I say: when it comes to sandpaper: they know what they're doing! What little money I saved buying the HF sandpaper, could not have been worth the time & hassle wasted on such an inferior product! The difference between the "tiers" of 3M sandpaper (woodworking, general, ultra, so on & so forth) isn't just the price. They actually have differing features, like the "grippy/non-slip" backing of the ultra I picked up.

Anyway. I hope this was helpful!!Last edited by Crawler; 10-23-2016 at 03:52 AM. Reason: Typo.

Decades away from full-beard growing abilities.

-

The Following User Says Thank You to Crawler For This Useful Post:

Hirlau (10-23-2016)

-

12-20-2016, 07:39 AM #59

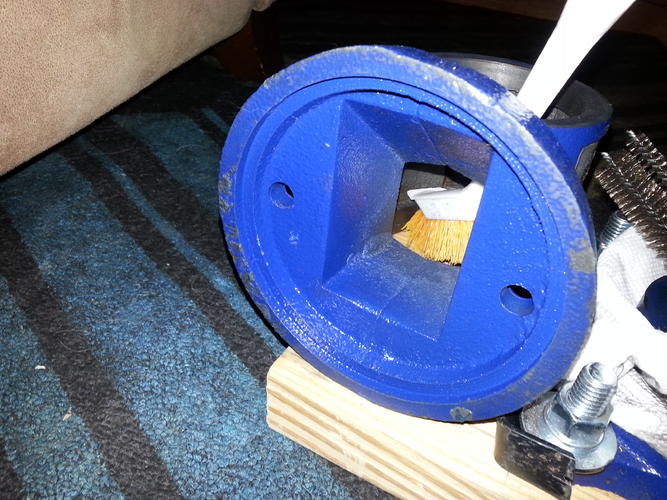

5" Multipurpose Vise!

5" Multipurpose Vise!

This post is less of a direct review, and, I guess, more of a buyer's guide. Or a setup guide? Either way, it's a vise. Those either work, or they don't

.

.

You should all probably know by now, the routine for buying stuff at HF. If at all possible, open the packaging & make sure everything is there, while in the store.

The reviews for this item, on the HF website, encourage taking the vise apart, cleaning it at a minimum, and lubing it before putting it back together.

"Daddy's little helper". He gets very curious when I do stuff down in his territory (anything below end table height).

Lacking a proper workbench, I mounted it to a couple pieces of salvaged 2x4 (mounting hardware not included). Now, I can clamp it to whatever suitable surface I have available.

As you can see, I got creative in order to mount in a way that wouldn't cause problems if I clamped it to a kitchen counter or something. It also solved the problem I had with the bolt heads being larger than any of my sockets lol. I just cut the recess in the shape of the bolt head, with a gouge.

I finally took mine apart & cleaned it, using dawn & various detailing brushes. I then dried it with paper towels, and left most of the pieces sitting on the vent for a day. With the heater kicking on when necessary, I feel confident that all the parts were dry.

Here is some gunk.

Now, I need to file/saw off some lumps left behind during casting. After that, lubrication & reassembly.

And the crap I need to file off.

I don't have any mechanical grease, so I will make do with Ballistol. Probably not ideal, but it will most assuredly lubricate & protect!

I looked when I was at the local big-box store, and this is about the only thing I could find that may be suitable. Though, I was hoping for something small & more economical, as I don't have... well... anything that needs greased with any regularity.

Thoughts & suggestions on the grease?Decades away from full-beard growing abilities.

-

The Following User Says Thank You to Crawler For This Useful Post:

Hirlau (12-20-2016)

-

12-20-2016, 08:06 AM #60Senior Member

- Join Date

- Dec 2016

- Location

- Bassfield MS

- Posts

- 105

Thanked: 23

That grease might be a little too heavy, or it might work fine. Me, I'd likely use what I have on hand, just basic molly grease I keep in grease guns. As an old man told me one time, "it's all greasy". A little simplistic, but it's a vise, your not spinning parts at 5,000 rpm.

You have to be careful when shopping at HF, but you can find some gems for sure. These days I mostly buy consumables like nitrile gloves, acid brushes, chip brushes, ect. I have bought other things in the past though. Like my surface grinder, the exact same model from Grizzly was another 400$, it did have a nicer paint job and a sheet metal stand, but for 400$ less I built a wood stand and can live with the flat grey paint. I bought a meat grinder from HF last year for 44$ with a 20% off coupon, the exact same grinder, same logo, everything, was a 100$ at Gander Mountain. I normally use name brand hand drills and power tools, but I needed a large hand drill for a one time project and if it dies tomorrow I'm fine as I only needed it for one project. I have a couple of there drill presses and while there not Snap-on, they do the job and one is over 25 years old. I also bought a horizontal bandsaw from them recently and wind up using more than I thought I would, just had to go over it and make sure everything was square and lined up properly. Any precision drilling I use my mill. I used to buy American made bandsaw blades from them until they jacked the price up to where I could get them cheaper somewhere else.

Two things I do not recommend, one is there vises, the casting is iffy at best. There OK for light duty, but don't work them hard, seen too many break and have had a few with really poor threads on the shafts. The other is there buffers, the motors are OK, but most I've seen are in the 3400 RPM range and that's unsafe in my opinion with anything larger than about a 4" wheel. I know many people use them, but I prefer a 1700 RPM for 10" wheels and safety. A buffer is the most dangerous tool in the shop, bar none. I know of one knife maker that the buffer grabbed the blade out of his hand, slung it into the floor and bounced back into the spinning wheel and slung it into his palm. Another got it stuck in his leg the same way. I also use a loose belt on a mandrel and a 1/2 horse motor, it's fairly easy to bog the buffer down so it keeps me from pressing too hard, also helps keep me from washing out lines and edges from over buffing.

230Likes

230Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote