Results 1 to 10 of 26

Thread: Dealing with heavy rust?

Threaded View

-

11-25-2016, 01:37 AM #1

Dealing with heavy rust?

Dealing with heavy rust?

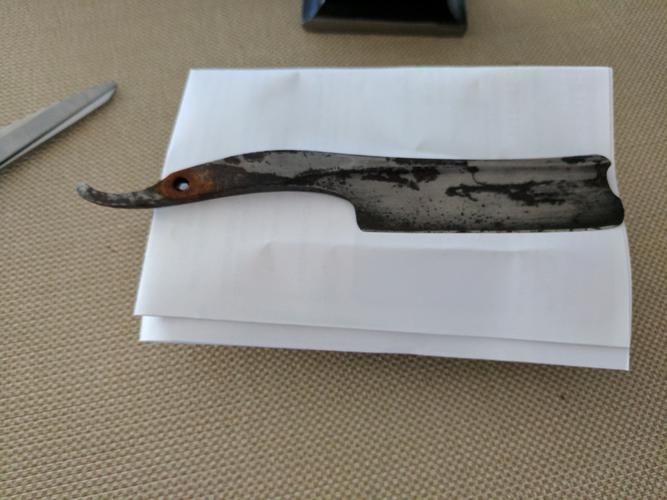

I started working on my second razor.

Here's how I got it:

Unpinned (and I didn't break the scales this time):

After some heavy 400 grit sanding:

It looks like the rust has damage the steel. Any recommendation on how to proceed?

62Likes

62Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote