Results 1 to 10 of 10

11Likes

11Likes

Thread: Sealing Wood Scales.

-

02-06-2017, 04:36 AM #1

Sealing Wood Scales.

Sealing Wood Scales.

I've been looking for options to seal wood scales. Wood is easy to work with, and easy to acquire. Mistakes are no biggie. So it is an obvious choice for self-education in making scales. I will undoubtedly move on to other mediums for scales. Maybe poured resin... probably about the time I build a vacuum chamber.

Back on topic! Sealers!

I don't care for CA glue; it is tricky to use, and I don't like the fumes. Many wood finishes don't completely seal the wood from the elements. I also only want a brush-on, not an aerosol. I don't know a ton about paints/finishes/etc., so I've been perusing the appropriate aisles when we are at the store, reading a lot. I read labels & descriptions & websites, followed by reading Wikipedia & related sources about chemical makeups and such.

Suggestions & help narrowing the field would be much appreciated. I'll list some I've considered thus far.

Thompson's Water Seal.

I saw a bunch of Minwax polyurethane finishes, but most might be stains as well. Currently, I just want a clear sealer. It is also hard to tell if they'd be safe to use on a hygiene implement. Also, from what I can tell, polyurethane finishes don't completely seal .

.

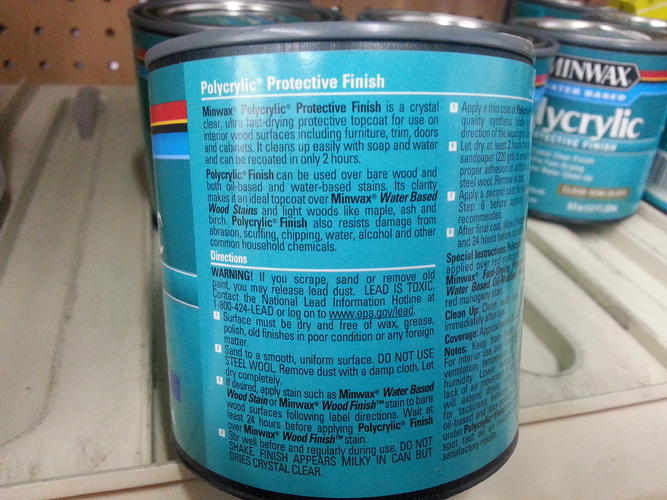

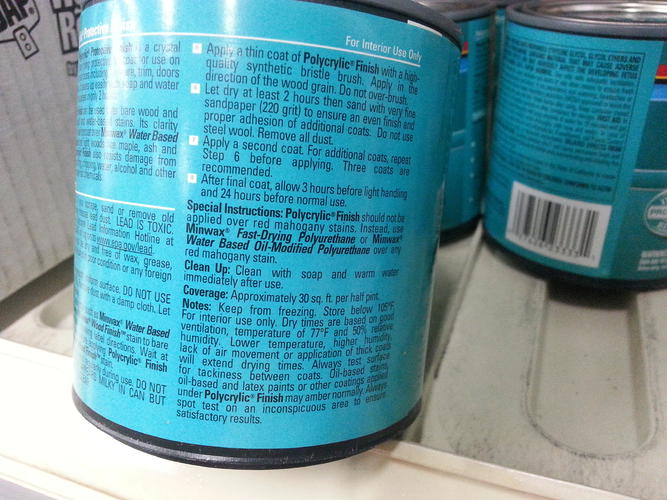

Also, this stuff:

It is certainly smaller than a gallon of Thompson's!

I took pics of the label info for my own notes, but why not...

I've only seen this particular product at one of the half a dozen or so big-box stores I've been in recently.

My first prototype scales are nearly complete enough to be useable!Decades away from full-beard growing abilities.

-

02-06-2017, 04:45 AM #2

I've used the polycrylic many times, and it works on oily woods. Another that us wood scale guys like is called " True Oil", made by birchwood Casey's. Its a gun stock finish, and boy does it pull out the natural colors and grain of the wood. But the polycrylic dries a lot faster. And cleans up with water.

Mike

-

02-06-2017, 04:56 AM #3Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

+1 to Mikes suggestions.

True oil is worth the time, every time.."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

02-06-2017, 05:42 AM #4At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

What kind of wood

See this is always the question ???

Different woods react differently to different finishes sometimes rather badly

One hint before finishing woods get in the habit of starting with an Acetone wipe down followed by a "Wash Coat" of your chosen finish..

This will give the best penetration, which is what we as Razor Guys are really after..

A Vacuum Chamber REALLY helps to get penetration into the fibers of the woodLast edited by gssixgun; 02-06-2017 at 05:52 AM.

-

The Following User Says Thank You to gssixgun For This Useful Post:

cudarunner (02-06-2017)

-

02-06-2017, 06:17 AM #5

The pieces of wood that I'm currently working with are, more than likely, pine. They are scraps cut from scraps of disassembled pallets. Not gonna "work out the bugs" on that nice junk of zebra wood I've got

.

Decades away from full-beard growing abilities.

.

Decades away from full-beard growing abilities.

-

02-06-2017, 11:25 AM #6

I thought they used hardwood in pallets. I don't really know.

I would say pine is definitely a practice wood.

If you do get the scales finished to your satisfaction, you should use a thrust bearing and washers.

Plus, I would use larger washers on the outside. Pine will be very easy to split with any heavy-handed pinning. A few taps and then sand, as Pixel used to say.

While you don't like CA, I have used CA on some soft, thin wood. Putting on several coats made the scales feel and behave almost like plastic.

good luckIf you don't care where you are, you are not lost.

-

02-08-2017, 03:07 AM #7

The most common type(s) of wood used to make pallets is SYP (Southern Yellow Pine) and Oak, respectively. Though, the exact materials can be a mix of any number of hard and soft woods. What determines the wood used is mostly abundance: whatever is common & cheap locally to the producer of the pallets.

Evergreen woods make sense because they tend to grow faster than deciduous (mostly hard woods) trees. The oak is mostly a byproduct of furniture & construction industries: the remnants & excess (and ugly) material is used for pallets.

Sources dug up in the past 24 hours:

https://en.m.wikipedia.org/wiki/Pallet

What The Heck Pallets Are Made Out Of? • 1001 Pallets

How to determine if a wood pallet is safe for use - AllDecades away from full-beard growing abilities.

-

04-15-2017, 03:46 AM #8

-

04-15-2017, 10:45 AM #9

-

04-15-2017, 01:13 PM #10

Birchwood Casey Tru-Oil just can't be beaten. Almost all professional gun stock work is done with this.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote