Results 1 to 10 of 10

10Likes

10Likes

Thread: Plane on bone?

-

03-26-2017, 05:11 PM #1Senior Member

- Join Date

- Aug 2015

- Posts

- 317

Thanked: 15 Plane on bone?

Plane on bone?

So I've out a few scales now. One of the more time consuming steps is thinning the blanks. I don't have a belt sander of any kind or a band saw. I do have a router and random orbital and a powered plane. (recent acquisition)

So far I've cut the blanks in half by routing a 1/8 cut out in bit of wood and using a HF pull saw to cut slabs, then moving to thinner cut outs or jigs and my random orbital to true the surface and bring it to my desired finished thickness.

The problem is the jigs are a bit sacrificial. I'm trying to dream up a jig that I can machine the surface down.

I envision a powered plane shattering or at least chipping bone or horn.

Router?

Thoughts?

Thanks.

Sent from my SM-G930V using Tapatalk

-

03-26-2017, 05:21 PM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

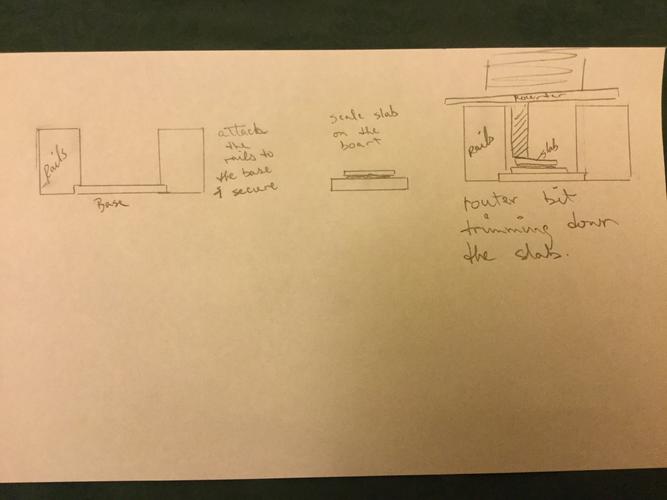

Well both bone and horn will do bad things in a planer. You can hand scrape them, it is a little faster than sanding. If you made a bed and a sleigh you could trim them down with a router before scraping and sanding. two rails with a base attached, a high board to slide between and secure with screws that will hold your slab. the slab attached to the slider board with double sided tape. the router base rides on the rails and the bit runs between the rails and skims the surface of the slabs. you will need a spiral down cut bit to make it pretty. if it is beyond your imagination let me know and I will doodle it for you. a picture is worth thousands of words.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

Geezer (03-26-2017)

-

03-26-2017, 05:34 PM #3Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

Something like this set up can help you thin material a little more quickly but it will not be a finished slab, it will still need some sanding and scraping to get it ready for scales. I hope my sketchy sketch is legible.It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

spazola (03-26-2017)

-

03-26-2017, 05:37 PM #4Senior Member

- Join Date

- Aug 2015

- Posts

- 317

Thanked: 15

I think I got cha... I was thinking base, rails and plexi top.

Sent from my SM-G930V using Tapatalk

-

03-26-2017, 05:47 PM #5At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,194

- Blog Entries

- 1

Thanked: 13250

here is a thread with a link to another thread about thinning Material

http://straightrazorpalace.com/works...ning-wood.html

-

03-26-2017, 07:26 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Belt sander is the way to go, if you don’t have a stationary belt sander, chuck a hand held upside down in a vice. 80 grit will get you flat quickly. Double stick taped to a 5 gallon wood stir stick keep your fingers out of the way.

Use the carpet tape, not the thin Scotch, though the scotch works well gluing the halves together when shaping.

You can actually get good control with a sander, keep a set of calipers handy and measure often. An inexpensive plastic set, is a time saver if you don’t have a good set, I keep a set in both cars, for measuring all kinds of stuff.

Yea, planers will chip.

-

03-26-2017, 08:08 PM #7Senior Member

- Join Date

- Aug 2015

- Posts

- 317

Thanked: 15

Yep, don't have a hand held one either. The random orbital work ok. Just trying to build a better mouse trap.

Sent from my SM-G930V using Tapatalk

-

03-29-2017, 11:31 AM #8

I've found bone to be very hard on files, planes, etc.

Before I had a good belt sander, using bone was very cumbersome. I have no good techniques to share for you.

I only started liking bone when I got to work it with 40 grit ceramic belts on a professional belt sander.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

03-31-2017, 02:41 AM #9

I've used belt sanders for many years shaping bone for guitar parts and now scales for razors. I love the smell of bone on a belt sander in the morning.

Last edited by MisterClean; 03-31-2017 at 02:42 AM. Reason: grammer

Freddie

-

03-31-2017, 02:54 AM #10

Freddie my friend, you and I are both old enough to remember the old cable driven drills that our dentists used. To me, working on bone smells just like those days when the dentist was drilling on my teeth, smoke was coming out of my mouth and I could smell the stench. I hate that smell!

For a little fun go back memory lane here:

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote