Results 1 to 10 of 10

-

09-23-2017, 06:03 PM #1Member

- Join Date

- Sep 2017

- Location

- Sundsvall, Sweden

- Posts

- 93

Thanked: 8 Some questions about, polishing, scales and the little wedge.

Some questions about, polishing, scales and the little wedge.

Soo I have starteded out with Gradwell razor, im almost done on one side of the blade. Just some dark pittings that I will remove with WD40 and steelwool 0000. The other side I will be more carefull with, since there is some text on it. Just steelwool 0000 and WD40 to clean it up and then some sandpaper on the other spots to get a smoother blade.

However I have a few questions.

The scales are black buffel horn. One is little shorter then the other and I have been able to straighten them out. But I think the drilled holes is a little bit of. If I put the pins through the wholes with blade and wedge they aint straigt.

Can I fill the wholes with epoxy and then drill new ones and make sure they are straight and even? Or is it a better way?

The wedge is little small and thin. Maybe its okey, but its a pretty wide blade and feels like it should be little thicker. But since im new to stragiht razor restauration im not sure how it should look, but wedges on other razors is thicker. (Its made from some soft metal i think)

Should I use it as it is, or can I make a new one. And what material is good in that case?

And also, the whole in the blade is wider then the once in the scales, I guess this wont be a problem, but is there anything I can do about that to or should I just go with it?

When it comes to polishing, I bought a machine that i modified to use for polishing. But what kind of metal polish is good to use on a spinning wheel polisher

Thats what I bought and I removed the stones and put some polishing weel on it instead. I now all about being carefull and soo, and im making sure not to go to long and heat up the blade to much.

Thinking of turning one of the original stones to a sanding machine, something like what I saw in the library. But thats in the future.

Soo really what Im asking is.

Best way to drill new wholes in scales if they aint even.

How thin should I wedge be?

What do I do when the whole in the blade is wider then on th scales?

What polishing compounds would be good to use. Enough with some typical white and blue?

Also woundering, the razor didnt have any inner washers, should I ad or not? Where do I buy if Im gonna ad them?

Thanks in advance

SvissonLast edited by Svisson; 09-23-2017 at 06:13 PM.

-

09-23-2017, 06:22 PM #2Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,048

Thanked: 636

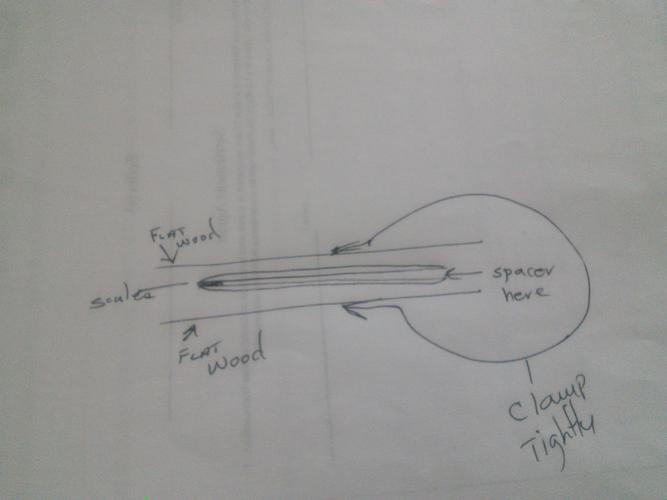

First I would try to straighten scales. Put a spacer material between scales and a flat piece of thin wood on each side of scales and clamp to keep tight. Let sit in hot water about 5 minutes. Remove and let cool. Remove clamp and see if scales are any better.

As far as polishing I would sand with 400 grit and finish with 1000 and 2000 grit. Hand polish with Mother's or any other metal polish.

-

The Following User Says Thank You to bouschie For This Useful Post:

Svisson (09-23-2017)

-

09-23-2017, 06:47 PM #3Member

- Join Date

- Sep 2017

- Location

- Sundsvall, Sweden

- Posts

- 93

Thanked: 8

-

09-23-2017, 10:10 PM #4

The wedge is made from lead

Mike

-

09-23-2017, 11:49 PM #5Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

So sometimes they are made uneven on purpose. Before you redrill anything take some nuts and bolts and mock it up. I recently restored a razor and everything was crazy crooked and I thought this will never work. Mocked it up and the blade closed dead centre, I was a little apprehensive about pinning it but once pinned the crooked pins in the crooked hole on the crooked scales with the crooked razor and it was perfect.

Mock ups show us a lot of things.It's not what you know, it's who you take fishing!

-

09-24-2017, 12:27 AM #6

-

09-24-2017, 12:44 AM #7

That’s what I thought for a long time, but it turns out they’re tin or pewter.

Also, here’s a link to my posts about working with horn.

There are a lot of tricks for straightening scales and also getting a razor to center.

Rezdog is right — sometimes scales are a little crooked to correct for a slightly warped tang.-Zak Jarvis. Writer. Artist. Bon vivant.

-

The Following User Says Thank You to Voidmonster For This Useful Post:

Svisson (09-24-2017)

-

09-24-2017, 02:36 AM #8Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

The scales were bent and twisted enough that it did not close at all before I straightened the scales.

It's not what you know, it's who you take fishing!

-

09-24-2017, 05:59 AM #9Member

- Join Date

- Sep 2017

- Location

- Sundsvall, Sweden

- Posts

- 93

Thanked: 8

-

09-27-2017, 11:06 PM #10

[QUOTE=Voidmonster;1772921]That’s what I thought for a long time, but it turns out they’re tin or pewter.

I believe the wedges were pewter. A low grade known as "lay" or "ley" metal, it was used for items that were not in contact with food or drink. It consisted of tin with 15% lead. Any of the old wedges I have seen were softer than tin. There may have been some tin wedges. Tin is slightly magnetic. If your wedge is tin it will be attracted to the magnet.

6Likes

6Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote