Results 1 to 3 of 3

Thread: Horn scale reconstruction

-

05-06-2018, 01:02 AM #1

Horn scale reconstruction

Horn scale reconstruction

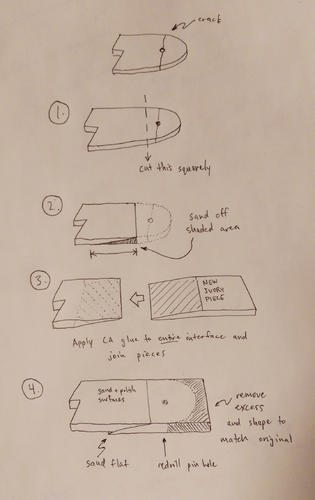

One of the ways I deal with breaks in horn scales. All repairs involve CA (cyanoacrylate / super glue). For fairly flat scales it can be done in 2 pieces, something I'd posted somewhere in the past, a la:

And an example of a razor where this was done:

The surface area of the joint is probably around 2 cm^2, so holding power with the glue is pretty good. It's not pretty (the old Sheffield black scales were really often translucent horn dyed on the surface, so any sanding reveals the lighter horn), but works.

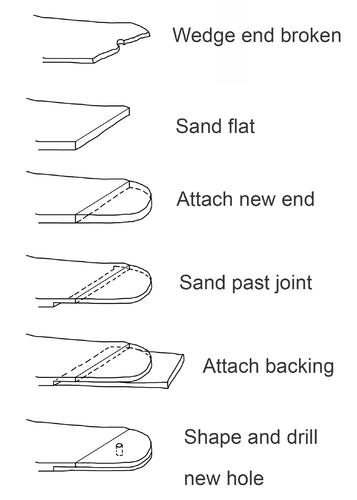

But for scales with a more domed cross-section, or where there's surface to be preserved, a squared off joint is preferable, but is very weak, so a third piece can be put in in the back to reinforce it. Pins could be put in for reinforcement but the surface area is pretty high so I think just the glue should hold up.

Today's project: a Greaves Lexington razor with pressed horn scales, that had a piece of scale missing at the wedge right across the hole:

Here is a closeup of the replaced piece, with some carving work to replicate the border:

The backing piece:

-

The Following 6 Users Say Thank You to ScienceGuy For This Useful Post:

BobH (05-06-2018), Geezer (05-06-2018), JBHoren (08-23-2018), markbignosekelly (05-13-2018), ShaveAndTravel (05-13-2018), spazola (05-13-2018)

-

05-13-2018, 01:14 PM #2

I've done a few with epoxy and bog oak, dust. Then coat the repair with CA, so it would polish up.

Mike

Mike

-

The Following 4 Users Say Thank You to outback For This Useful Post:

Geezer (05-13-2018), markbignosekelly (05-13-2018), Oldnick (05-30-2018), ScienceGuy (05-13-2018)

-

05-13-2018, 04:55 PM #3

Those look really good. How do they hold up in the long term? I've had a number of horn repairs break a year or two down the line.

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote