Results 11 to 16 of 16

Thread: Extreme Bow/Warp in Horn Scales

-

09-08-2018, 11:22 PM #11

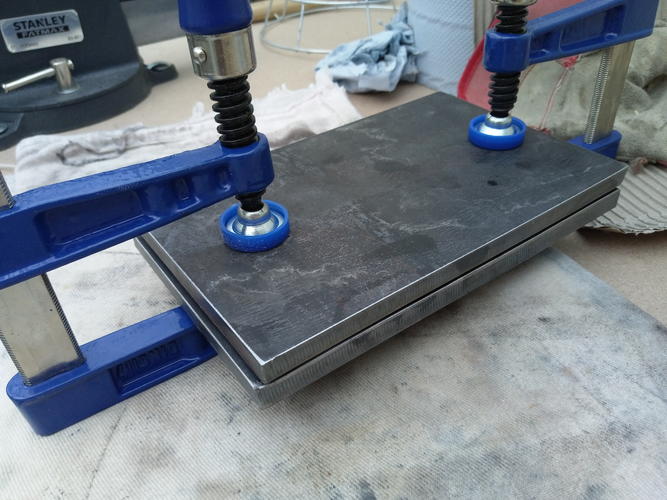

I took advise from Outback on how to heat these scales from a Stodart.

Soaked them in Neastfoot for a week . Heated under a lamp . Flexed them . Then clamped um.

Just be careful when bending hot horn in the opposing direction, they can stretch.

-

The Following 2 Users Say Thank You to JOB15 For This Useful Post:

MikeT (09-08-2018), ScoutHikerDad (09-09-2018)

-

09-08-2018, 11:34 PM #12

I can see how stretching would be a problem ,

First thing that comes to mind is that it could throw off the blade centering..

.. if one gets worked more than the other and stretches a bit..“You must unlearn what you have learned.”

– Yoda

-

09-09-2018, 11:14 AM #13

The cool part about horn. If the blade doesn't center, you can heat the the scales with a heat lamp while pinned, and tweak them a bit to center. Or place a piece of paint stick between them to open them up, and get the blade further into the scales. Kinda takes place of shimming the tang on the ol Sheffielders.

Mike

-

The Following 2 Users Say Thank You to outback For This Useful Post:

MikeT (09-09-2018), ScoutHikerDad (09-09-2018)

-

09-09-2018, 12:01 PM #14

Hey thanks, that's something I didn't put together yet even after reading that they can stretch. The benefits of a material that plasticizes..

On another subject; I was just reading the wood-database.com , great site! They have this "periodic table of wood" poster, very cool! You guys might check that out.

On the topic of glue/finish not sticking to oily wood there is a good article. Has a couple good points.

One concept was that water-based glues/finishes don't work on oily woods, so using a solvent to wipe surface oil off, like has been suggested on this thread .. and also using a glue/finish that is meant for synthetic materials like plastic..

I've worked with African Blackwood a bunch (very oily and tight wood), a big factor in getting it to stick for me has been to create significant "structural adhesion". This is easy if you are laminating two pieces together because you can scratch up the surface really deep.

I actually used a razor held at an angle to cut angled grooves crisscrossing the surface that the glue (CA) could soak into and "grip" the surface. This was to laminate Red Coolibah Burl to African Blackwood.

But for a "show" surface, one would have to see what the lowest grit that can be used before it affects the look.

Anyway, just thought I'd share that. I'm all about exotic woods, and hope to have a collection again. For all you wood enthusiasts this is a great site. Here's a link. There's also an article on drying woods at home!

https://www.wood-database.com/“You must unlearn what you have learned.”

– Yoda

-

09-09-2018, 12:50 PM #15

TBH Mike, I use the MinWax polycrylic finish, for oily woods. Its a water based finish for wood, and I've had no problems with it.

Mike

-

09-09-2018, 01:33 PM #16

Good to know thank you.

Perhaps it's not as big an issue?

It was simply suggested by a couple sites. When I used CA, it was not that I knew of such suggestions, I simply was using CA because it was what I had.

If that product works better, I think I'll end up buying some, as I know you have ample experience with finishes. Is that preference through comparisons with finishes meant for plastics and other less adhesive surfaces? What did it work better than?

EDIT: My apologies I just realized that I hijacked your thread. I get carried away...Last edited by MikeT; 09-09-2018 at 01:39 PM.

“You must unlearn what you have learned.”

– Yoda

32Likes

32Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote