Results 1 to 10 of 17

-

03-31-2019, 03:35 PM #1

Technique, Source and Thickness for Brass Sheets for a Wedge?

Technique, Source and Thickness for Brass Sheets for a Wedge?

So I haven't had nearly as much time to rescale razors lately, I've got a couple of gorgeous big Sheffield naked blades I'm planning to do soon. I want to do one in streaked brown horn (cuz I'm a masochist) with brass collars. As I try to learn a new technique with every rescale, I'm thinking of doing a bone wedge lined with thin brass as I've seen on here occasionally. I think it looks beautiful and classy, and maybe I'm kidding myself, but hopefully not that hard to do?

I'm assuming you just get your wedge rough-sized, shaped and finished on the scale-facing flats, then glue the sheeting on, clamp, and cut/sand/fit and finish as one piece like you would do with any wedge? If it helps, I generally sand and polish the rear face of the wedge, fit and peen, then finish out the wedge end on a succession of belts on a 2x72 grinder. Any tips on this? Am I kidding myself and this is a very advanced technique?

And yeah, a source and thickness for the brass sheet would be awesome too! Thanks-Aaron

-

03-31-2019, 03:49 PM #2

Never done it myself but ive seen brass sheets at the hobby store. I will be watching, but i think your plan is about what i would do.

It's just Sharpening, right?

Jerry...

-

03-31-2019, 04:25 PM #3Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,813

Thanked: 563

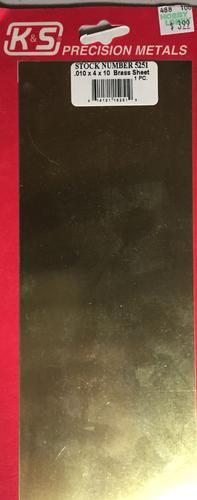

Got this at Hobby Lobby.

David

David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

The Following User Says Thank You to DZEC For This Useful Post:

ScoutHikerDad (03-31-2019)

-

03-31-2019, 04:42 PM #4

Thanks-We have one of those across town! So .010" on thickness?

-

03-31-2019, 04:46 PM #5Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,813

Thanked: 563

-

03-31-2019, 05:13 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Any good independent hardware store or hobby shop will carry a selection, it is not expensive. My local Ace has a good K&S selection down to .005 in a bit thicker than copy paper, that can be cut with scissors or knife.

As to thickness, that is up to the look you are after, keep in mind the over all thickness will affect how deep the razor will sit in the scales when closed.

Place the blade between the scales and mark the tip at the top of the scales. Measure the thickness of the blade at that mark and make that the overall thickness of the wedge at the thick part. So, adjust the bone part of the wedge to get the proper thickness with the 2 sheets of brass. I work from 1x1 inch pieces and glue the 3 pieces with super glue.

Cut the bone and brass slightly, 1/16 in larger with jewlers saw, or belt sand, after the wedge is made. Drill your pin hole to 3/32 in, shim the wedge to drill a straight hole. The larger hole allows for slight adjustment.

File or sand to final shape once the scales are fully pinned and blade centered.

Sand to high grit and polish. Not hard at all and no special tools needed, just a bit fiddly to get the thickness right. Gluing the 3 pieces will make it easier.

-

The Following 2 Users Say Thank You to Euclid440 For This Useful Post:

Paulbuck (04-01-2019), ScoutHikerDad (03-31-2019)

-

03-31-2019, 08:05 PM #7

Thanks Marty and Dave-On the hunt for the brass sheets locally. I'm also gonna look for bones in the pet shops that I can cut down-never sourced bone for razors before. I'll figure something out-I kind of enjoy making weird materials into wedges anyway.

edit: In prowling around the web for ideas, I see that Brad Maggard has a bunch of wedges lined with brass in his gallery-I like a lot of his scale aesthetics too!Last edited by ScoutHikerDad; 03-31-2019 at 09:10 PM.

-

04-01-2019, 01:14 AM #8Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

You can get clean bone or antler from Pet stores, I bought some nice sized antler from Home Goods, an over stock discount store. I think I paid 3-4 dollars for a 6 inch piece.

Antler is pretty cool, depending on what they were eating prior to shed, will tint the color of the antler when buffed. It looks like marble, I have made scales that are tinted Pink, Green and Ivory.

It works easily with wood working tools, haven’t made wedge but made some nice bone folders with the scraps. It is hard and polishes up smooth and bright with green rouge.

Check a fabric store or even a thrift stone for bone buttons.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

ScoutHikerDad (04-01-2019)

-

04-01-2019, 02:59 AM #9Senior Member

- Join Date

- Feb 2016

- Location

- pennsylvania

- Posts

- 302

Thanked: 66

i memory serves, i think i bought 28 gauge (0.012) off ebay. both brass and nickel make nice wedge liners.

-

The Following User Says Thank You to sloanwinters For This Useful Post:

ScoutHikerDad (04-01-2019)

-

04-01-2019, 03:35 AM #10

Brownell's sells shim stock from .001 to .015. Here is a link. https://www.brownells.com/gunsmith-t...k-prod589.aspx Cheap and easy to use. Austin Kennedy sells some really nice bone blanks which you can find on eBay. Here is an example of a wedge like you describe.

I'm sure a search will give you numerous ways to make the wedge although using a 2x72, as you describe, in successive belts is way over kill. Just get it close on a belt and finish with a hand file, abrasive paper and polish on your buffer. Do not rough grind your wedge assembly until you have it assembled in the scales with micro fasteners. The heat generated from grinding will most likely break the glue bond.

I'm sure a search will give you numerous ways to make the wedge although using a 2x72, as you describe, in successive belts is way over kill. Just get it close on a belt and finish with a hand file, abrasive paper and polish on your buffer. Do not rough grind your wedge assembly until you have it assembled in the scales with micro fasteners. The heat generated from grinding will most likely break the glue bond.

-

The Following 2 Users Say Thank You to karlej For This Useful Post:

ScoutHikerDad (04-01-2019), Toroblanco (04-01-2019)

29Likes

29Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote