Results 1 to 10 of 12

-

01-20-2020, 02:50 AM #1Senior Member

- Join Date

- Dec 2016

- Posts

- 283

Thanked: 61 230 Douris - Handsanding Does Almost Nothing

230 Douris - Handsanding Does Almost Nothing

Hi folks,

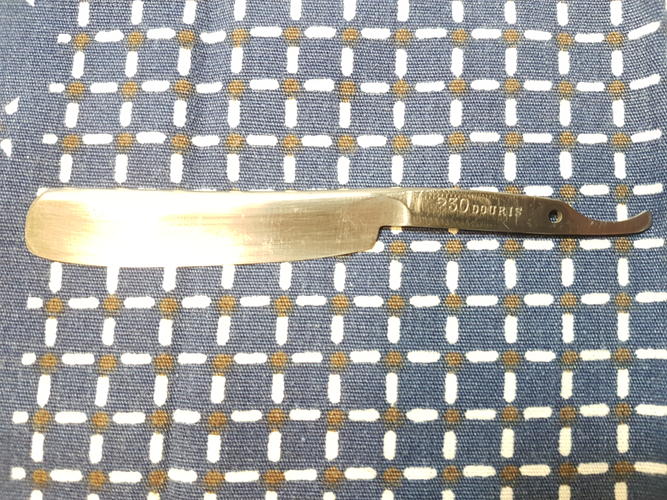

I recently got my hands on a 230 Douris wedge for cheap. I know almost nothing about the razor aside from some speculation that it is French in origin. It originally came with some old, slightly warped black horn scales with some bug bites in them. Knowing I needed to do something about them, I've taken them off and am slowly restoring them: straightening them out, applying neatsfoot oil, and sanding them up to 3000 grit.

Initially, I thought the blade itself was fine but it had a few spots and flaws in it so I thought, it's apart anyway, why not just do it right and treat the blade right too. Here is the problem: I've been handsanding for HOURS on wet-dry 220 and there is barely a noticeable difference. I tried a 150 wet-dry sanding block (really meant for wood) and that did even less. What is going on here? Is the steel in this razor really that hard? Am I overlooking something? Notablely, it seems that the person who had this before also tried their hand at some restoration and I'm sure used a dremel (I think) or something because you can see some minor vertical lines across the blade from where it jumped a bit.

I've attached a few photos -- sorry for the poor lighting and photos, something that is definitely not my strength. If anyone has any suggestions how to proceed or insights into what I'm doing wrong here I would be most appreciative.

Kind regards!

Paul

-

01-20-2020, 03:12 AM #2

I hope this link is of some help.

https://www.filofiel.com/tiendaonlin...age=en&sort=1a

Seems likely that it's the same company that made your razor BUT they seem to have dropped making razors quite awhile ago.

Perhaps contacting them might produce some information Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

ppetresen (01-20-2020)

-

01-20-2020, 03:30 AM #3Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

It’s important to use SIC wet dry paper. It is typically black in colour, and works well with WD-40. Typically I start at 1000 and decide from there how far to drop or if I want to go finer and polish it up. 0000 steel wool and WD works great for a good deep cleaning.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

ppetresen (01-20-2020)

-

01-20-2020, 03:36 AM #4Senior Member

- Join Date

- Dec 2016

- Posts

- 283

Thanked: 61

Thank you! I'd googled around but didn't find much. Just for the sake of curiosity, I will get in touch with them.

Yes, I'm using 3M 220 SIC wet dry, but just with water. I've never tried using WD-40 with it though, I'll give that a try! I'm pretty sure I have some 0000 steel wool hanging around too. Cheers!

-

01-20-2020, 04:14 AM #5

I find wd40 or kerosene to be pretty good lubes for hand sanding steel. If you aren’t using some sort of backer for the sandpaper try that too as it will help save your fingers as well as allow you to use more pressure.

-

The Following User Says Thank You to jfk742 For This Useful Post:

ppetresen (01-20-2020)

-

01-20-2020, 05:14 AM #6

+1 to using a backer. I've found finger pressure to have too much "give" with hard steel. A wine cork backer really helps the sandpaper bite into the steel, it will also save you some finger pain.

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

-

The Following User Says Thank You to JellyJar For This Useful Post:

ppetresen (01-20-2020)

-

01-20-2020, 08:57 AM #7Senior Member

- Join Date

- Dec 2016

- Posts

- 283

Thanked: 61

Thank you. I have used a papermate white eraser as a backer and that works ok. I've also tried a wine cork but especially since the wedge has an essentially flat profile on both sides, the rounded cork really reduces how much surface area of the sandpaper is making contact at any given time. I think I'm going to try cutting a cork in half when I try adding in the WD-40.

Also, I did contact Douris Chastel and they got back to me very quickly. Unfortunately, they are not the manufacturer nor have they ever produced straight razors. He did say it was quite a common name in the area, though, but he couldn't tell me who or what company it might have been. So, that mystery at least continues.

-

01-20-2020, 11:54 AM #8

I have experienced what you describe as almost fruitless sanding.

It will get better but can take a while. It is as if the blade was case-hardened. Case hardening has been discussed in threads but I don't believe anyone found proof of a manufacturer actuality doing it as part of the hardening process.If you don't care where you are, you are not lost.

-

01-20-2020, 04:13 PM #9Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

Shaping your backer helps a lot, so does changing the sanding direction.

It's not what you know, it's who you take fishing!

-

01-20-2020, 04:33 PM #10

23Likes

23Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote