Results 21 to 30 of 31

Thread: My first razor I made myself

-

02-17-2020, 02:25 PM #21

I watched your grinding video. I have a couple suggestions. It will help if you grind the edge thickness to about 0.7mm before heat treatment. This leaves a lot less to remove when the steel is hard.

After heat treatment, slow your belt sander way down, and grind with the belt wet. This will preserve the temper of the steel.

I hope this helps.

-

02-18-2020, 08:28 PM #22Member

- Join Date

- Apr 2017

- Location

- Poland/Warsaw

- Posts

- 59

Thanked: 13

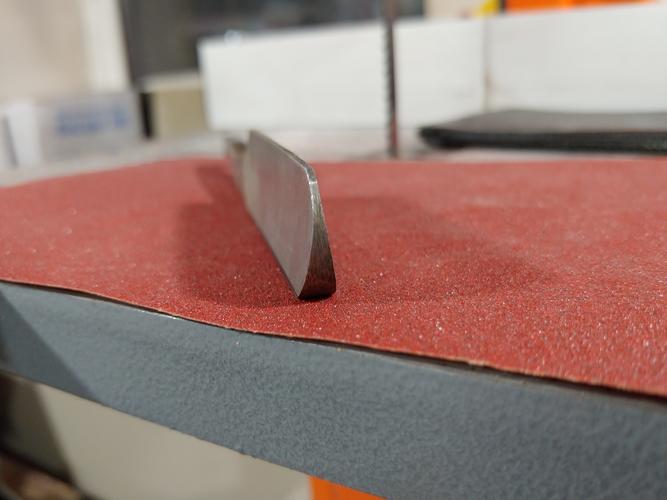

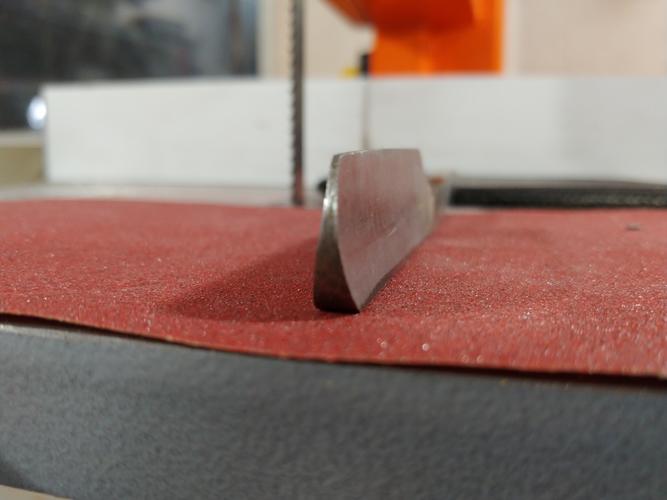

@Tim Zowada thank you very much for your suggestions. it's very nice of you. I continued working in the basement today.

https://youtu.be/oTMezFnkINc

-

02-19-2020, 01:53 AM #23

Very impressive - i wish i had a basement like that and i wish i had your talents with my hands

keep going!

-

02-19-2020, 06:20 AM #24

Well done, keep going!

As the time passes, so we learn.

As the time passes, so we learn.

-

03-11-2020, 01:51 AM #25

Outstanding work! I too wish I had a shop like that, basement, garage shed or BEDROOM even. Very nice and impressive work. I have 2 attempts in the fail box. Hopefully the next will be a.success.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

03-11-2020, 02:58 AM #26Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

-

03-11-2020, 03:05 AM #27

Well, in fairness I have been on a quest to make one from an old file. Not the easiest thing since most are bordering on too thin already before grinding and the metal is not that easy to work with. The road less traveled so to speak but at least I know I have 18 more files to destroy.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

03-11-2020, 02:33 PM #28Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209 Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

03-11-2020, 04:20 PM #29

Man Randy, that’s fast.

Did you ever get that razor to take a stable edge? The one you ground from a file at the meet?

-

03-13-2020, 03:00 AM #30Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I have not taken the time to buff off the residue from the salt pots yet.

Then I will hone and test shave with it . I also need to test shave that razor made by Andy Lewis from 1075 steel.

My energy is finally coming back so I can start working on necessary stuff.

Yeah, that Wilton grinder basically burned/destroyed every edge. There was no way to do a finish grind on it. It was because of that experience that I decided to build my No Weld Grinder. It was a good decision.Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

108Likes

108Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote