Results 1 to 8 of 8

13Likes

13Likes

Thread: Robeson rescale

Threaded View

-

04-18-2020, 10:18 PM #1

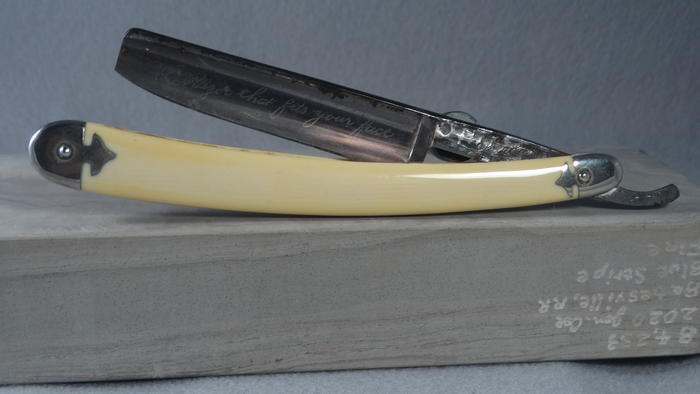

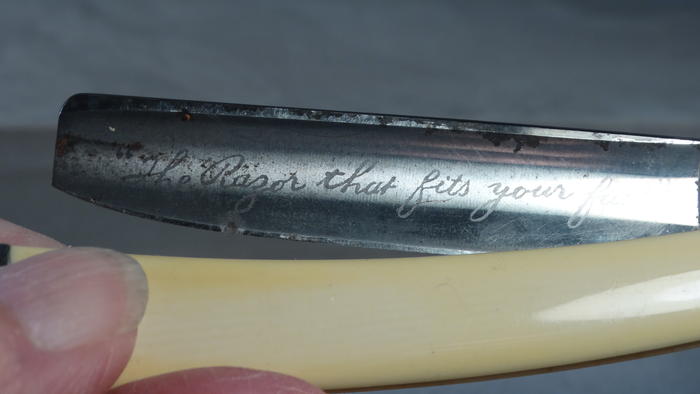

Robeson rescale

Robeson rescale

I purchased this razor so I could reuse the scales.

The blade has a lot of tarnish could it be cell rot. Will litmus paper between the scales detect cell rot?

The pivot pins appear to be nickel silver. Where can I buy this material.(found on ebay) If you enlarge the last photo you will see that the pins are domed. How can I get the old pin out without damaging the bolster?

What advice can you offer? I have rescaled other razors, without bolsters. I have a dremel in a press that I can use or I can drill by hand.

Last edited by boz; 04-19-2020 at 12:42 AM. Reason: nickle silvr pins

A healthy skepticism of both old and new ideas is essential to learning.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote