Results 1 to 10 of 45

Thread: Metal lathes

-

06-10-2020, 02:47 PM #1Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829 Metal lathes

Metal lathes

I am wanting to buy a metal lathe. I have very limited experience. I do know that there are a few here that have a lot of experience.

I want to do some small wood turning as well as metal turning. I am leaning towards the Taig system from Lee Valley. There are a number of fancier metal lathes on the market. I do not have space for two lathes.

I know so little on the subject that Iím not completely sure what questions to ask.

Can I turn wood on any metal lathe as long as I am careful about not letting my chips lay all over the bed?

Are any of the small lathes remarkably better than the others?

Are there any features that I should be making sure my potential new lathe has?It's not what you know, it's who you take fishing!

-

06-10-2020, 03:21 PM #2

I know Bill Barber used a fairly hefty metal lathe for brushes.

I reckon the proper attachments and gouges/tooling would garner same results on a small metal lathe.

B52 should know. I shall fetch him.......

-

06-10-2020, 03:57 PM #3

I think Bill used the metal lathe for ivory

If you don't care where you are, you are not lost.

-

06-10-2020, 04:01 PM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

B52 has several lathes and I am hoping he will have a grand response to my questions. I’m hoping as time passes we can also discuss the ins and outs of various tooling. I have a lot to learn!

It's not what you know, it's who you take fishing!

-

06-10-2020, 04:18 PM #5Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

I have a small Jet wood lathe and a Smithy Midas metal lathe/mill. I have used the metal lathe for wood. It worked fine. In order to do so I made my own tool rest. That was about the only modification or extra tooling that I needed. I used my regular wood chisels to cut the wood by hand. The biggest reason for using one over the other when woodworking is due to the headstock. I needed a large three jaw chuck and I don't have one for the Jet. Typically I use the Jet when woodworking though. I have more mounting options (screw chuck, drill chuck, etc...).

-

06-10-2020, 05:04 PM #6

I did a lot of reading on these as i was wanting one too. But then after learning about all the tools and attachments that go with it i stepped back and figured maybe one day but for now i can wait.

Good luck Shaun. It sounds like a great tool to have. I will be watching for what ya make.It's just Sharpening, right?

Jerry...

-

06-10-2020, 08:37 PM #7Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Thanks for the note Tom.

Missed this new thread Shaun.

I do own a few lathes and am not an expert on any of them, but can turn a good part when I need.

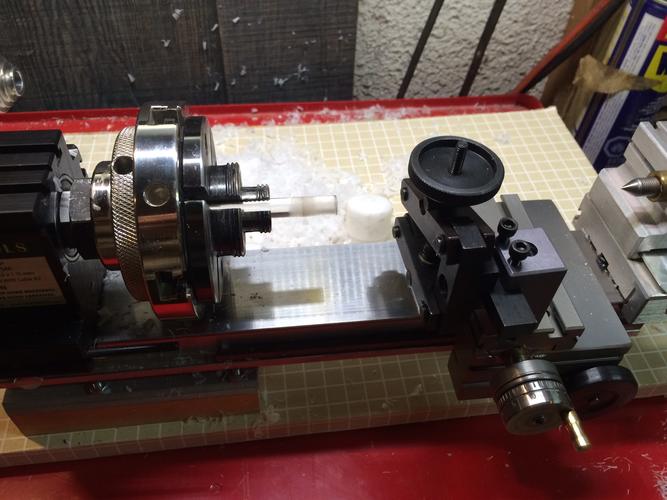

The Taig is a very good, but small, bench top metal lathe.

It can turn, with the table lift, up to 6” diameter pieces, but you need to be aware of, and be ok with changing the jaws for different jobs, and or machining multiple sets of jaws for various reasons.

Luckily the metal chuck jaws are aluminium and easily modified.

I have mine on a vfd dc 90 volt motor so never worry about the pulley’s.

I actually mounted the whole affair on top of a typical 6 drawers tool chest, so that will give perspective in the size.

For your location the size works well to ship Shaun, and if you are staying below the above diameter with your projects, I can’t speak highly enough to the accuracy of the lathe.

You can buy it as either wood or metal shop biased. I’d recommend go metal as you can always fab up the tool rest for wood, vs the other way around.

Quick change tool post really isn’t too necessary but the compound slide I found really is.

So the taig, for metal shop, plus the bed extenders, compound slide, assorted tool bits and some good quality 1/4” and 3/8 key stock to make custom bits are really the must haves.

The 4 jaw as well as 3 jaw chucks to flip from metal to wood projects.

Those will set you up for great project possibilities.

If you don’t have a dc drive, a 1hp ac motor will work well with the speeds in the sprockets. I just happened to have a spare kit on hand.

Hardest thing I find is hand control on the manual feeds to give that last polished pass.

I hesitate rolling across 12 o’clock and that always shows up as a smudge in the finished work..

Nothing a wee bit of wet sand doesn’t erase, but still.

Truly, I’d rather have the taig and not need it than the other way round..

Last edited by MikeB52; 06-10-2020 at 09:35 PM.

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following 5 Users Say Thank You to MikeB52 For This Useful Post:

BobH (06-10-2020), Geezer (06-10-2020), RezDog (06-10-2020), rolodave (06-10-2020), ScottGoodman (06-25-2020)

-

06-10-2020, 09:38 PM #8

After working in a machine shop for a number of years before i started my current job i have always dreamed of having my own. there is so much you can do with a metal lathe. Right now i am saving up for one and have settled on the mini lathe from harbour freight. I really like the Taig but the deciding factor (with price in mind) is the fact that you can't turn threads with it.(as i understand). From what i've read the HF lathe does require some fine tuning but (and there is a web site dedicated to it) is a serviceable lathe for the price point. One of the longer ones would be a little better but i have space issues.

Those are my thoughts as of now but i'm also open to ideas as it's going to be a while before i can afford one.

-

The Following User Says Thank You to tintin For This Useful Post:

Gasman (06-11-2020)

-

06-11-2020, 12:08 AM #9Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

I’ve almost pulled the trigger on a bigger Asian hobby lathe for the same reasons Tintin. The stock taig will not cut threads.

But a CNC converted taig sure will.

Sort of on the “to do” list still."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

06-11-2020, 01:56 AM #10

All very interesting stuff. I have always wanted a lathe, a milling machine, an extruder and a good forge. In my line of work I could really use it. sometimes you need a part you just can't put your hands on and it sure would be nice sometimes to be able to just make them. Of course a nice sheet metal break and some punch machines would be nice also...not to be greedy but hey,

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

185Likes

185Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote