Results 1 to 10 of 42

Thread: Scales Experiment.

Hybrid View

-

07-17-2020, 01:23 AM #1

I think i spent a total of 2 hours today on the green but I was melting the milk jug in layers and sprinkling the green between them. I would say depending on quantity and size of pieces at least a good 45 to an hour and a half using a toaster oven at about 330-350. It will have the consistency of a very stiff dough.

-

The Following User Says Thank You to joamo For This Useful Post:

Johntoad57 (07-17-2020)

-

07-19-2020, 02:59 PM #2Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

I played with making some last night. It is kind of the damascus of plastic. I don't think that I got mine hot enough though. While it looked good and felt strong, I cut it up and then bent it to test the "welds". In the middle of the piece I had the equivalent of "cold shuts". So I'll melt it back down and give it another try later today.

-

07-19-2020, 05:24 PM #3

That is a big plus that the rejects and scrap can all be remelted and tried again.

I'ts a learning process too, my clamping rig has too much flex and I'm dealing with varying thickness because of it. I may rig up a frame and use a scissor jack and steel plates.

Pressure helps a lot with squeezing out the cold shuts.

-

07-19-2020, 08:19 PM #4

I think that an Arbor Press may be your friend instead of the scissor jack. I have the Harbor Freight and it works OK. I did some fine tuning by smoothing things up a bit but straight from the box it worked fine.

https://www.harborfreight.com/1-ton-...ress-3552.html

If you picked up some 1/2" steel plates, then filed the edges and the surfaces you could then sand the surfaces smooth right down to a mirror finish. I'd take the turntable out and lay the bottom plate directly on the flat surface then the melted plastic and top plate and then press it.

If by chance the angle of the handle isn't where you can get good pressure, the ring on the right is held in with a single set screw, you can loosen the screw remove the ring then pull the shaft with the handle out till you can move the ram up or down till you can get the right angle.

You could do that before by experimenting with how the set up would be before hand.

I'm also wondering if those polished plates could be preheated with the plastic to give you more working time Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

07-19-2020, 09:12 PM #5Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Great minds must think alike. I too have that arbor press, but I ended up using a large vice with steel plates. I found that preheating the steel plates not only helps with a longer working time, but they really help with the finish of the plastic. Warm plates make the plastic much smoother on the outside. Here is my second attempt from today. This time I let the plastic get hotter (almost puddling) and it didn't have any cold shuts. These are just rough cut and sanded down to 60 grit. One thing I noticed. While this material is extremely strong, it is soft and bends easily. I'm not sure how thick to make the scales. They won't give much (if any) tension due to flex. They will simply flex.

-

07-19-2020, 09:39 PM #6

@DVW, those look good!

My first HDPE scales mike at .19 inch each, thick but not out of line for a beefy blade in my opinion.

The flex is reasonable and behaves as scales should, no point of looseness noticed as the blade rotates.

My next set will be thinner and I'll report back on those.

@cudarunner Excellent suggestion, I'll probably get an arbor press once I pick up more hours. Covid cutbacks hit hard.

-

07-19-2020, 11:14 PM #7Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

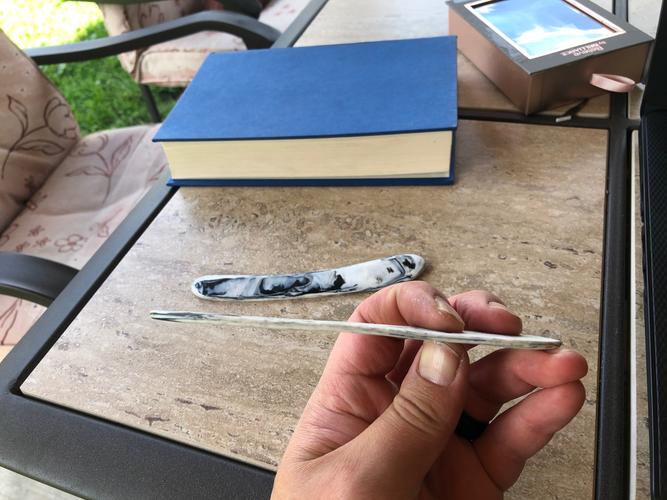

It's not the "looseness" that has me concerned. It is the lack of any "spring" or memory that this martial has. There will not be any tension due to the spring action of the handle material being bent. As you can see below. This stuff bends really easily and can be bent right back to the previous shape without any sign of memory or "set" being taken. I think that even if I get the blade centered in the scales, it won't take but a little side pressure to make it not close on center.

I was thinking the exact same thing. The issue with that is keeping moisture out from between the two materials. Most adhesives will not bond to this stuff.I think some thin brass, G10 etc is in your future

Here they are cut much closer to shape and polished. They look good. Now to make them functional.

-

07-19-2020, 09:45 PM #8

138Likes

138Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote