Results 1 to 10 of 18

Thread: HORN SCALE QUESTION

-

03-13-2021, 05:31 AM #1Senior Member

- Join Date

- Aug 2020

- Location

- Roseville, CA (30 minutes north of Sacramento)

- Posts

- 246

Thanked: 7 HORN SCALE QUESTION

HORN SCALE QUESTION

Hey, Peeps...I have a question for y’all.

I have a really smooth-shaving razor which I want to make scales for.

I wanted to try something different, so I chose horn.

The company which I purchased it from had two levels of horn quality.

“Seconds” - which were bowed or warped. But they say they are still workable, and can be steam corrected.

And then they had the more expensive horn scales...which were not bowed or twisted, and had no other colors within them. (I’m ordering black Buffalo horn scales).

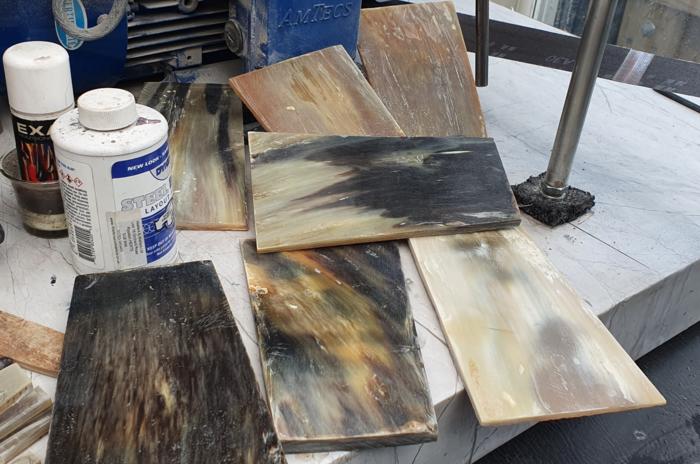

So I chose the better quality horn scales (which were more expensive) and I received this. (See attached photo).

Now, I’m no horn scale expert, but this scale is twisted, and is nowhere near flat.

So here’s my question:

Is this normal?

Since I am working with buffalo horn, is a perfectly flat scale not really expected?

And if this is totally acceptable for buffalo horn scales, what is the best way to steam them flat?

Or...should I return them as defective?

As a side note, I have a baby bottle sterilizer. It sterilizes with steam. Can I stick it in there for the sterilization cycle, and then place it on a flat object with a steel block on top of it?

Just curious what y’all have to say, as I’ve never worked with buffalo horn before.

Thanks.Last edited by RaymondMillbrae; 03-13-2021 at 05:37 AM.

You can follow me on MeWe at "Wet Shaving Universe".

-

03-13-2021, 08:45 AM #2

Are there two pieces? If it is one piece you will have to saw itin two. A band saw is the easiest way. I use a wooden sled to saw bone and horn.

How thick are they?

How long are they?

Looks ok to me. I use a heat gun and weights to flatten horn. A hair dryer should work. Hot horn is very pliable but not for long. Have your "press" ready to go when you heat.

Good luckIf you don't care where you are, you are not lost.

-

03-13-2021, 10:49 AM #3

Id cut the basic shapes out first. Then with heat(i use a heat lamp, many was to go about it) make them very plyable. Then press as Dave said while hot. Its not hard to do. But making them closer to shape to start with means you are working with less material.

It's just Sharpening, right?

Jerry...

-

03-13-2021, 11:46 AM #4

I use an old clothes iron to heat, then press it flat. Its the fastest way I've found, yet.

Mike

-

03-13-2021, 01:25 PM #5

As to your question about if that is normal consider the shape of a cow horn. Buffalo horn is similar in shape. Now it is cut then spread out and pressed flat.

I have never used a steam heater but I don't see why you couldn't. You can also immerse them in hot water then clamp them between 2 pieces of wood but make sure to dry them off first. Whatever you do to heat them you will need to clamp them while they are still hot and pliable. Especially if you use water to heat them with be prepared to leave them for a couple of days.

You are going to have to shape them though so you may want to do that first. You may not have to flatten them as much once they have been thinned down. Horn has a kind of memory for shape sometimes they will tend to revert to the warped shape. I am working with a pair now that I have flattened repeatedly and they keep warping back some. Sometimes you may have to flatten them several times.Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

03-13-2021, 04:01 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yup, normal.

As said cut to rough thickness and shape first, less material to work. Then use steam, hot water, or heat gun, they all work. Once heated it is very pliable, I clamp in a wooden bench vise. Once cool they are stable, if needed I reheat with heat gun and bend to final shape by hand.

Here is a great tutorial on making horn scales, by Karlej. You can sand or scrape to shape, scraping is fast and easy to do, make a scraper from a putty knife.

Sand to 1000 grit and polish with a good metal polish or stainless compound on a buffer.

How to make a traditional set of horn scales ... the way I do it.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

32t (03-13-2021)

-

03-13-2021, 05:02 PM #7

You did right, getting the higher quality horn for your first attempt. Cut your scales to size and slightly over finished thickness, before straightening them, because when you cut your scales out, they may warp again when released from the supplied piece. Be sure to use a proper wedge and not a flat spacer. Your finished thickness should allow the scales to flex inward to the razor pivot, after being spread outward by the angle of the wedge.

Horn can be hard to work with but it can make some beautiful scales. Boiling or steaming works. Heating in an oven works. Slightly over-correct the warp so it can spring back a little as it cools, which it likely will. You may not get it flat enough to suit you in just one session. Or you may get lucky and get a piece of horn that cooperates fully with your artistic vision. You never know, with horn.

Camel bone makes nice scales, too. At first glance it looks a lot like ivory. It is not quite as springy as horn. And some woods are nice, particularly ebony, ziricote, birdseye maple, etc. But horn, especially translucent or honey horn, really looks nice. Drills without shattering or chipping. Sands and polishes easily, If you can tame the warp, everything else is easy sneezy.

-

03-13-2021, 06:12 PM #8

I sell and use a lot of horn and bone. Honey horn tends to warp the fastest and dark/black horn seems to last longer on the shelf as blanks. What you received looks ok to me and is certainly workable. all horn willeventually warp on the shelf, unless bound. As others have said, Cut them lengthwise first. Then shape them roughly into scales. Sand them down on both sides, or use a scraper, then apply heat to them. Then put them in a press to hold their shape to cool. Any kind of heat application works, I use an electric hair straightener. Do final progressive sanding with sandpaper then polish/buff. Using double sided tape helps to drill holes and sanding. Measure both scales frequently throughout the process with a digital caliper to ensue both scales are the same thickness. Watch Karl Johnson's tutorial. I find Horn is easy to work with and fun. Good luck with your restoration

Last edited by ajkenne; 03-13-2021 at 06:17 PM.

-

03-13-2021, 08:21 PM #9Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

"What you received looks ok to me and is certainly workable. all horn will eventually warp on the shelf, unless bound.”

Another good reason to use a proper fitting wedge, as opposed to a spacer.

Of all the materials available, horn is the easiest to work, finish and look great. It can also work well thinned, not as thin as Ivory but pretty thin.

-

03-13-2021, 09:14 PM #10

Horn can warp with water or heat and some is more stable than others depending on how it was processed ..

It is my favorite scale material..Have a look at a few stunning pieces i selected today..This is Ox horn, more tricky to work with compared to buffalo but a better material i think..(That is Red / Orange at the back)

55Likes

55Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote