Results 11 to 20 of 28

-

06-02-2008, 05:13 PM #11

-

06-02-2008, 05:18 PM #12< Banned User >

- Join Date

- Feb 2008

- Posts

- 3,763

Thanked: 735

Looking good so far. If the pitting bugs you, just keep sanding until it is gone (you may want to move back to 320 for a while for faster removal). Simple hand sanding will eliminate pitting eventually, just time & effort.

Or, just hone it up as-is and you'll be psyched!

-

06-02-2008, 05:40 PM #13

I'm also going to offer encouragement for you to try honing that razor up and bringing it back to life. Encouragement with a caveat........

Yes, naturally, honing to good steel will get you the necessary shaving edge you need. But....does that razor have good steel that's accessible across the entire edge? Before those quick to answer with a "Yes" answer that question, in my experience, pitting on an edge can make or break a razor. Others disagree; I recall someone within the last few months who said he has no problem getting great and comfortable shaves from at least some restored edges that are pitted in places (trouble is I don't remember who said it).

To me, good steel on both sides of the bevel (resulting in good steel across the entire edge) is crucial for a consistent comfortable shave.

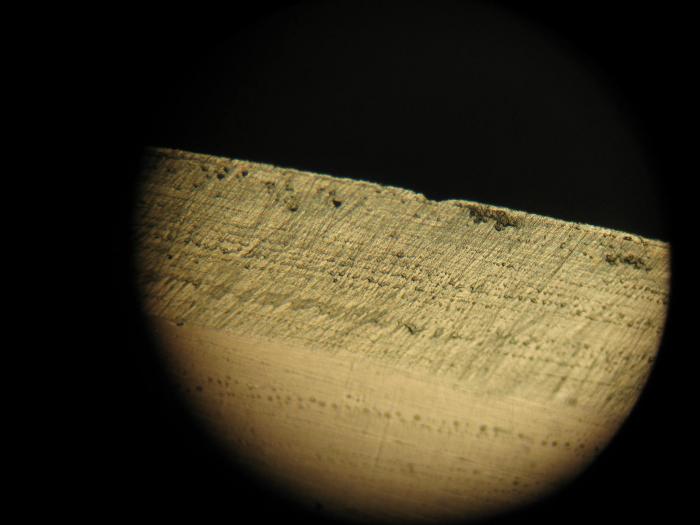

Here's a pic on 40x of a pitted edge on a razor I had some time ago that was pitted on the edge (type/name of razor doesn't matter for the pic, I'm posting to illustrate my point):

Note what looks like a chipped area on the edge to the left of the pitted cluster not yet affecting the edge. It's not a chip. It's a pitted area "opened up" or revealed right at the edge. Now view the pitted cluster to the right of that "chip"; honing into that cluster will reveal more "chips" (again, not chips, but you know what I mean). Honing would have to be past that whole cluster. While not an impossible task by any means, over the entire edge, that's still removing a significant amount of metal. And, were there other pits further up the past the bevel that after honing past the cluster in the picture would have been revealed along other places on the blade's edge? I don't remember, but it's possible. That would mean essentially chasing the pitts up the blade farther and farther in search of a truly even keen edge removing more and more steel.

I think of pitts like bubbles in swiss cheese. If the bubbles are revealed at the point of an angle (the edge) they become jagged serrations. I argue that these jagged serrations compromise the razor's edge, fold over easier, and provide overall for a less than comfortable shave. That's been my experience.

I've had some other razors that I bought early on in this hobby that were very rusted/pitted. Even after cleaning up the rust, the edges of those razors were so pock marked and pitted, they were really worthless as shavers.

People have different sensitivities to things. What makes for a less than comfortable shave for me may not be an issue for others. For me, I don't like pitts on edges at all. I have not found a razor that has been good enough to be in my rotation that has problems that I talk about here.

Chris LLast edited by ChrisL; 06-02-2008 at 05:46 PM.

"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

06-02-2008, 05:50 PM #14

Wow! Thank you for the information. I'll take a close look at the blade tonight.

Christopher =)

-

06-02-2008, 06:12 PM #15

If you DO see pitting at the edge, to be clear, I'm not advocating with my previous post that you forget trying to hone that razor. I think it's true that different people have different experiences depending on their sensitivities. Even with pitting, properly honed, that great example of Sheffield steel absolutely may serve you well. You don't know until you try.

Guys that DO have uncomfortable shaves from vintage razors for no apparent reason may want to examine the edge closely and look for the microchipping.

Chris L"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

06-02-2008, 06:16 PM #16< Banned User >

- Join Date

- Feb 2008

- Posts

- 3,763

Thanked: 735

Can't that edge pitting be simply remidied by more aggressive honing? Similar to honing out an edge chip. Sooner or later you will hit "virgin steel", and it will be all sweetness from then on out.

-

06-02-2008, 06:39 PM #17

Maybe. I say that because it depends on the razor and a razor's degree of pitting. I agree with you, hitting or honing to "virgin steel" across the entire edge would definitely yield a great edge. I was trying to explain my point as best I could; IF the random placement of pitting on the bevel area and just above is such that you hone past one pitting cluster but in the process bring another one to the edge on another part of the edge, you're chasing those pits back and forth back and forth. Again, depending on the razor, absolutely you could finally get to a point where you'd have fresh uncompromised steel across the entire edge. I've found, for razors with rusty edges (actual rust rather than patina has always revealed significant pitting for me underneath) prior to restoration that I've never been able hone past the pits left behind. The sides of the razor and even the faces of the bevel (even though they contribute to cutting) don't shave whiskers, it's all about that amazingly thin line, the edge. Pits on the edge are the absence of steel, a jagged serrated area.

Chris LLast edited by ChrisL; 06-02-2008 at 06:41 PM.

"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

06-14-2008, 03:16 PM #18

-

06-14-2008, 04:22 PM #19

Ray! It's great to see you here, man!

Awesome!

Me =)

-

06-14-2008, 04:50 PM #20

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote