Results 1 to 10 of 40

Threaded View

-

08-05-2008, 06:18 PM #1At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,072

- Blog Entries

- 1

Thanked: 13249 An Illustrated Guide to Un-pinning and Re-pinning

An Illustrated Guide to Un-pinning and Re-pinning

With all the questions and such that come up on pinning razors, I decided to take the time and some pics, and put this together, while I was on this next restore.... I apologize for some of my pics in advance I just ain't that good

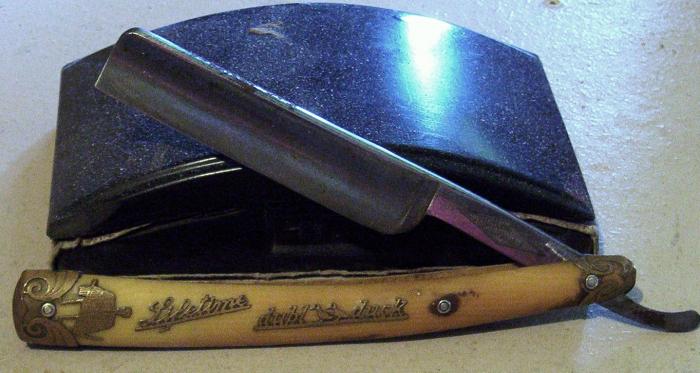

We are starting with a DD Reaper that is going though a complete restore... So first I am going to pop the pins... There are a few ways to do this, and if I were intent on keeping the scales, I might use one of the other ways ie: a drill press or Dremel to drill out the pins... For this guide, I used the least expensive tools, and NO power tools so it would be of the most benefit, to the most people...... (these scales are shot, they are rotted through, even though it doesn't show in the pics)

Always start on the back side of the razor,

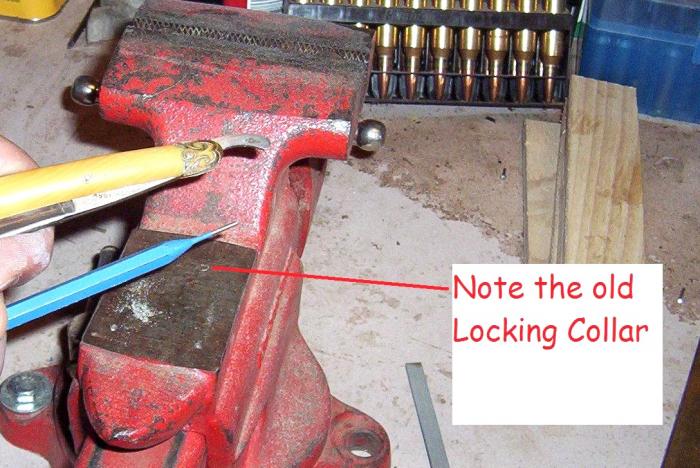

if there is going to be a locking collar, it will be on the back side, this DD has them...If you look close you will see that the razor is held steady in one of the small dimples that I have drilled into the anvil side of the bench vise.... I file gently, and slowly, until that collar pops off, then I use a 1/16 drift pin to tap the pins out... I tried to show why a lot of these scales will crack when you do this, it is not yer fault, look at how bent up these pins are when they come out.... So go SLOW you might save the scales.... once the razor is released I take out the center pin, then the wedge pin, and break the razor all the way down.... All I used here was the file, the drift pin, (any small pointy thingy) and a jewelers hammer, oh yeah, and a bench vise......

The front side or Show side of every razor (note direction not the name plates)

The back side of every razor ( I have heard of left handed razors out there, but have never actually seen one, they would be reversed)

Here are some pics of what I was talking about above......

Note the small dimple in the anvil...pic 1

Note the collar next to the drift pin on pics 3 & 4

Last edited by gssixgun; 08-06-2008 at 02:32 AM.

-

The Following 8 Users Say Thank You to gssixgun For This Useful Post:

andrewmurray86 (05-26-2014), awk5 (10-03-2008), boballman (02-13-2011), etorix (02-19-2013), Leofric (10-31-2008), MW76 (02-06-2016), netsurfr (08-05-2008), porridgeorange (02-12-2011)

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote