Results 61 to 70 of 103

Thread: Double Arrow Quality ?????

Threaded View

-

05-19-2009, 11:28 PM #1At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,204

- Blog Entries

- 1

Thanked: 13250 Double Arrow Quality ?????

Double Arrow Quality ?????

OK guys we have been buying into the notion that these are OK, and hey I have honed a couple dozen and they are OK, not great, not even good, but they do give a passable shave, and for the price??? wow!!! what a deal ... I bought into that, until today... This is what I found after having some fitting problems on scales.... Hey I by no means think that I am perfect but I have made a few sets of scales, OK a few hundred sets, and every now and then you do find a warped tang/spine and you actually question your own ability to cut a piece of wood straight

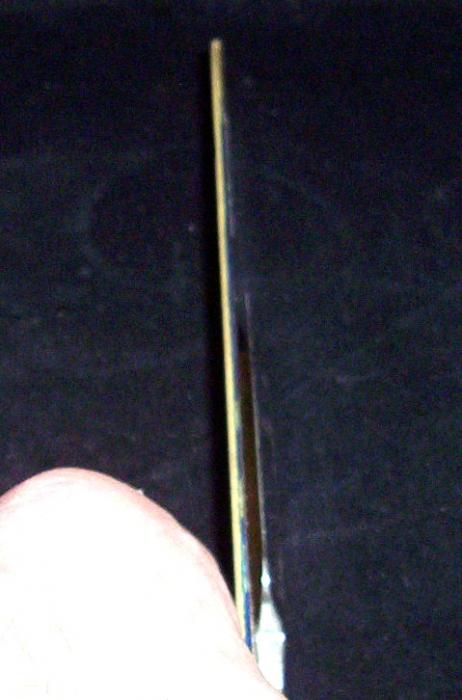

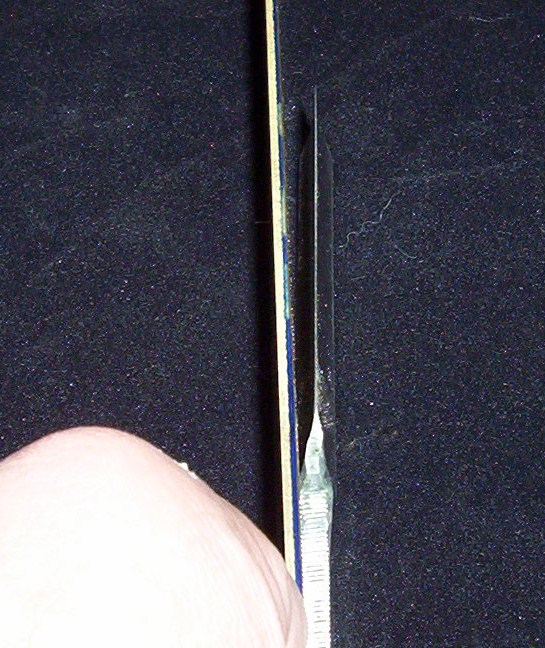

Here is what I found on just checking 4 DA's against a known flat surface, I am holding the tang flat against the brass with my thumb look at not only the deflection away from the brass but also the curvature in the grind.... 1 out of 4 is pretty straight....

Pic #1 is OK then look as they get worse #3 and #4 are way way off

Last edited by gssixgun; 05-19-2009 at 11:32 PM.

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote