Results 1 to 7 of 7

-

09-08-2005, 02:10 AM #1

secureing the grip on a Dovo Bergischer Lowe

secureing the grip on a Dovo Bergischer Lowe

I have a Dovo Bergischer Lowe with a loose black grip/tube thing. It looks like heat shrink tubing? Any one have any luck glueing this in place? It slides back and forth, and water gets under it. Help. Thanks, Tim

-

09-09-2005, 02:16 AM #2

I have the same razor and its loose also. I don't think it was ever supposed to be tight. its just a grip to help you hold it more securely. If you wanted something tight there I would just cut it off and either use nothing or try and fit a piece of rubber. Maybe a piece of that shrink to fit stuff they use for electrical connections.

-

09-16-2005, 12:28 PM #3

- Join Date

- May 2005

- Location

- St. Louis, Missouri, United States

- Posts

- 8,454

- Blog Entries

- 2

Thanked: 4942

I have one that I use frequently and the grip simply wore off. Puma's also had a similar grip piece of rubber. I would hate to glue one back on, but you could always dremel off any excess should you wear through it. I wouldn't think it worth it to remove a blade just to put a new one back on if you could find one. I look at this like goldwas......once it's gone.......it's gone. Obviously this message is of little help. Sorry. Lynn

-

09-16-2005, 04:48 PM #4

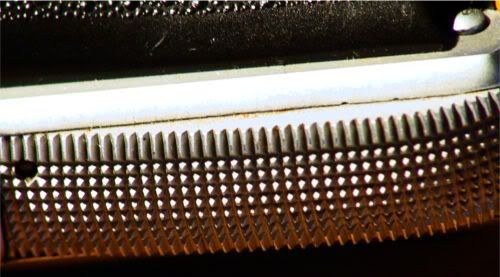

You're better off just letting it go until it falls off or gets too dangerous. A classier solution to that grip is to either find someone who is good with a triangular file, or try yourself, and file cross-hatchings into the tang (carefully, and patiently) similar to the checkering gunsmiths put on the steel grips of pistols they combat-customize. If the filing pattern is done correctly, that will prove a better and longer-lasting solution.

You're better off just letting it go until it falls off or gets too dangerous. A classier solution to that grip is to either find someone who is good with a triangular file, or try yourself, and file cross-hatchings into the tang (carefully, and patiently) similar to the checkering gunsmiths put on the steel grips of pistols they combat-customize. If the filing pattern is done correctly, that will prove a better and longer-lasting solution. Originally Posted by bones59

Originally Posted by bones59

Bill Wilson's shop did these pistol grips on a M1911A, as well as other neat stuff.

-

09-16-2005, 06:30 PM #5

Nice gun. I came close to getting a Wilson once, but ended up with a Les Baer Custom. Have you seen them? Excellent work with very tight toloerances.

Nice gun. I came close to getting a Wilson once, but ended up with a Les Baer Custom. Have you seen them? Excellent work with very tight toloerances. Originally Posted by uthed

Originally Posted by uthed

I have some checkering files somewhere. If I can dig them up I will offer them on loan for members needing this type of treatment.

-

09-21-2005, 07:21 AM #6< Banned User >

- Join Date

- May 2005

- Posts

- 1,304

Thanked: 1

Not trying to dampen anyone's spirits, but that triangular file may not work too well on a tang that is probably the same number of the c scale of rockwell hardness as the blade. I think you will get frustrated, and you will ruin some files.

Heat shrink tubing won't work unless you take the blade off the scales.

You could use that stuff used to put rubber handles on tools. It comes in a liquid-like form in a can. With patience, I think you could probably paint a new one on a little at a time. It has to dry between coats. Figure out a way to make the razor the focal point of a rotisserie. Light coats, and keep it rotating. It should work fine. You could pick cool colors, too

-

09-21-2005, 04:03 PM #7

I wonder if you don't need a special file, like diamond to work on that blade.

Originally Posted by uthed

Originally Posted by uthed

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote