Results 1 to 8 of 8

Thread: Ever Heard of a Stiddy?

-

09-30-2009, 09:43 AM #1Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164 Ever Heard of a Stiddy?

Ever Heard of a Stiddy?

I stumbled acros reference to "a Stiddy" on the "Vintage Sheffield Folders" forum and thought that it may be of interest to some members. It was a small anvil with cut-outs, used by razor-setters to assemble the component parts of an open razor. Here are a few pics:

The one above shows Tom Renshaw's stiddy (he was Billy Hukins setter-in at J & W Raggs Little London works in the 1970s). The two white dots are cup-shaped depressions into which the pins were placed in order to dome the ends.

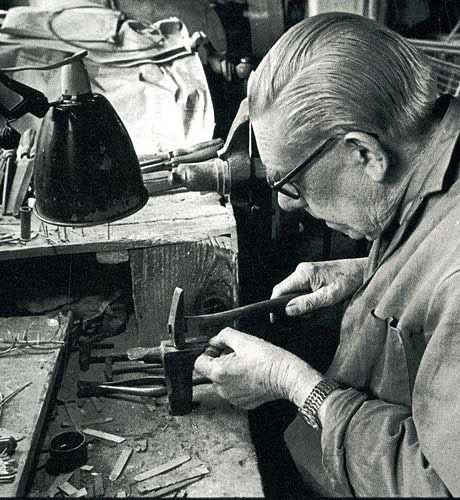

Above: Ernest Mills working at his stiddy.

The tapered square cross section of the stiddy was put into a hole on the worktop. The name may be a corruption of "Steady" because it 'steadied' the work and didn't move when hammered on. The blademakers used larger anvils called 'stithies'

The setter-in would also produce the domed washers for the pins - Tom Renshaw used a sheet of lead over which was placed a thin sheet of latten (an early type of copper alloy like brass, made into thin sheets by battering it with steam hammers). He had a "two circle" tool which he hammered into the latten, producing the following:

You can just make out that they are not pierced - the "two circle" tool must have been a round punch hollowed out into a cup shape but with another small circle (hence "two circle") in its middle, to produce a depression in the head of the domed washer through which the pin was driven. The washer/pin must have then been placed into the depression in the stiddy, the scale-blade-scale-domed washer assembled over it and the whole peened together.

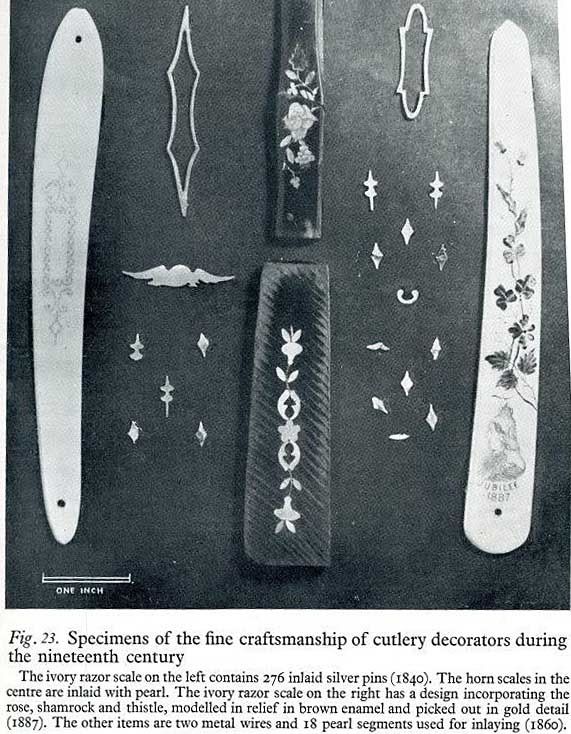

The setter-in had other duties too, like decorative pin-work (called pique-work) and scale inlays:

Regards,

Neil

-

The Following 14 Users Say Thank You to Neil Miller For This Useful Post:

0livia (09-30-2009), aroliver59 (09-30-2009), ChrisL (09-30-2009), dnjrboy (09-30-2009), DPflaumer (09-30-2009), FTG (09-30-2009), JeffR (09-30-2009), joke1176 (09-30-2009), keenedge (09-30-2009), Lynn (09-30-2009), matt321 (10-01-2009), Slartibartfast (09-30-2009), spazola (06-08-2013), Walt (09-30-2009)

-

09-30-2009, 12:06 PM #2

Interesting. Is that a notch or slot in the first picture? If so, what was that used for?

-

09-30-2009, 12:08 PM #3

WOW.Wonderful old pics and great information.Thanks,Neil......

-

09-30-2009, 12:30 PM #4

That was actually very interesting.

I kind of want one now. I feel like it would make my first attempts much easier.

-

09-30-2009, 03:04 PM #5Razor honing maniac

- Join Date

- Jun 2009

- Location

- On the beautiful St. Croix river

- Posts

- 228

Thanked: 51

I tried to navigate around that sheffield site and did not work.

Where did you get the pic's? Post the link to it please.

Thanks,

Bill W

-

09-30-2009, 03:34 PM #6

Very cool!

The head of the stiddy looks very simular to the top anvil part of my bench pin.

Just cut a slot in the front and use a round burr to make the two half round sets to the side. The benchpin also clamps onto the end of the bench, so that might be a neat idea for guys to try.

John

-

09-30-2009, 04:58 PM #7Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

The notch is something to do with pocket-knife springs, I think. The tool was used by all sorts of cutlers, so I imagine it had a host of uses. Some of the websites I have visited mention a "spreader" part - apparently it was placed between the liners of a knife (or razor?) when it had been over-peened in order to open it up a bit.

The website that includes the vintage sheffield folders is British Blades.

I found another, clearer picture of two old stiddies on another site:

and a US company called Great Lakes Waterjet, Inc make a high-spec, lasercut modern version:

...it will set you back $350 though! I think I'll stick to my tiny jewellers anvil with the holes drilled in it...

Regards,

Neil.

-

The Following 2 Users Say Thank You to Neil Miller For This Useful Post:

keenedge (09-30-2009), turbine712 (09-30-2009)

-

09-30-2009, 05:10 PM #8Beard growth challenged

- Join Date

- Feb 2009

- Location

- Berlin

- Posts

- 1,928

Thanked: 402

Wonderful to see!

Thanks for posting this.

2Likes

2Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote