Results 1 to 10 of 12

Thread: Buffer/Polisher

-

06-02-2010, 09:45 PM #1Senior Member

- Join Date

- Aug 2008

- Location

- Russellville Ar. from NEW ORLEANS, LA.

- Posts

- 1,035

Thanked: 172 Buffer/Polisher

Buffer/Polisher

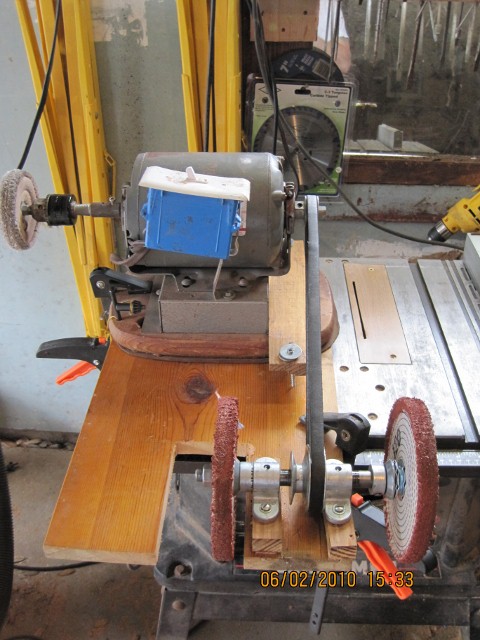

Thank you everyone for your input. I finally got my buff/polish put together. Any improvement comments welcome,

also, any critisim [ well not really]

yea OK guess i 'll welcome that too !

Consider where you will spend ETERNITY !!!!!!

Consider where you will spend ETERNITY !!!!!!

Growing Old is a necessity; Growing Up is Not !

-

06-02-2010, 11:07 PM #2

A very interesting modification, and a cool way to get an extra wheel. IMO the cutout around the 80 grit wheel makes it look like you won't have much room to maneuver, but one would have to try to know.

-

06-03-2010, 12:40 AM #3aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

I love ingenuity at it's best. It looks like it should work fine (does it?) and is modifiable as well. Interesting use of a drill chuck as well!!

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

06-03-2010, 01:10 AM #4Senior Member

- Join Date

- Aug 2008

- Location

- Russellville Ar. from NEW ORLEANS, LA.

- Posts

- 1,035

Thanked: 172

Acually it does work, no problem with manuvering because of cutout.

Consider where you will spend ETERNITY !!!!!!

Growing Old is a necessity; Growing Up is Not !

-

06-03-2010, 04:41 AM #5Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Your on our way now!

You will find that drill chuck to be very versatile. You might want to keep an eye out for additional large pulleys so you can slow the speed down even more. Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

The Following User Says Thank You to randydance062449 For This Useful Post:

paco (06-04-2010)

-

06-03-2010, 12:29 PM #6

Your buffer set up rocks! I like it.

Charlie

-

The Following User Says Thank You to spazola For This Useful Post:

paco (06-04-2010)

-

06-04-2010, 02:43 AM #7

-

06-04-2010, 02:47 AM #8Senior Member

- Join Date

- Aug 2008

- Location

- Russellville Ar. from NEW ORLEANS, LA.

- Posts

- 1,035

Thanked: 172 Consider where you will spend ETERNITY !!!!!!

Consider where you will spend ETERNITY !!!!!!

Growing Old is a necessity; Growing Up is Not !

-

06-08-2010, 08:35 PM #9

Hi Steve,

Hope I can answer this without confusing you too much.

Remember in school when we all said "when will I ever use algebra?" This is a time when we will.

The circumference of a circle is (PI) multiplied by the Diameter where PI is aprox. 3.14.

Your drive side runs at 3450 rpm, you multiply this times our circumference which gives us a value for the drive side. You have an unknown RPM and the circumference of the driven pulley. Because the two sides are connected by a belt they are interconnected by the belt speed and can be set equal to each other.

3450 rpm * ((PI)*1.5") = unknown rpm * ((PI)*2.5")

(3450 * 4.712)/7854 = Unknown rpm = 2070 rpm

So this speed reduction means your 6" buffer is spinning at 2070 rpm since it spins at the same rate as your pulley.

However, if you want to know the rate that the outside edge is going by your razor, you will utilize part of the process we did above again.

2070 rpm * ((PI)*6")= 2070 rpm * 18.85 in =

39,019 inches per minute which if you divide by 60 to get it into the form of per second gives 39,019 / 60 = 650 inches per second.

So the rate that the polishing wheel edge passes the razor blade will be 650 inches per second.

Hope this helps and that I did not confuse or bore you too much.

A site that gives a visual of the first part is Determining Pulley Speeds

-

The Following User Says Thank You to Noswad For This Useful Post:

paco (06-09-2010)

-

06-08-2010, 08:51 PM #10

Hey Paco! One of MUrphy's rules of combat states,"If it is stupid but it works, it aint stupid!". Well done my friend, thanks for the pic.

It is easier to fool people than to convince them they have been fooled. Twain

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote