Results 1 to 8 of 8

Thread: Grinding Wade and Butcher help

-

04-15-2011, 02:50 AM #1< Banned User >

- Join Date

- Mar 2011

- Location

- Chicago

- Posts

- 92

Thanked: 13 Grinding Wade and Butcher help

Grinding Wade and Butcher help

So I have this W&B wedge that I've been working on, and I've put a 3" sanding wheel on my drill to have a go at the blade to take the pitting out. Pitting is kind of deep. What harm can be done by grinding down to the bottom of these pits? As in, how deep can I go before affecting the integrity of the razor? I see the very edge crumbling away, as to be expected, and I'm a little nervous about rushing forward without asking this question.

Thanks in advance

-

04-15-2011, 03:00 AM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,165

- Blog Entries

- 1

Thanked: 13249

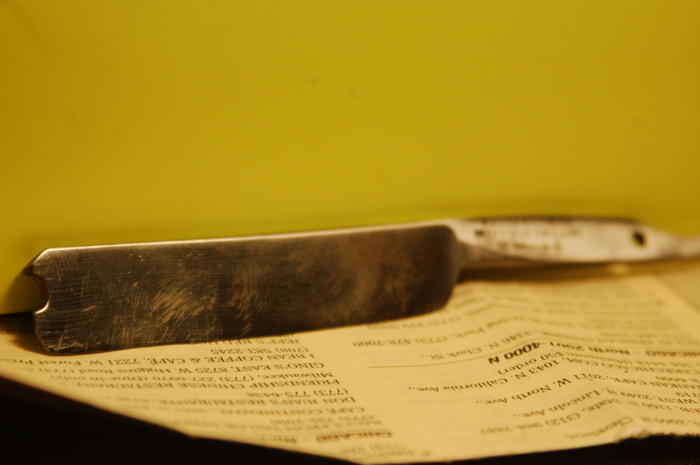

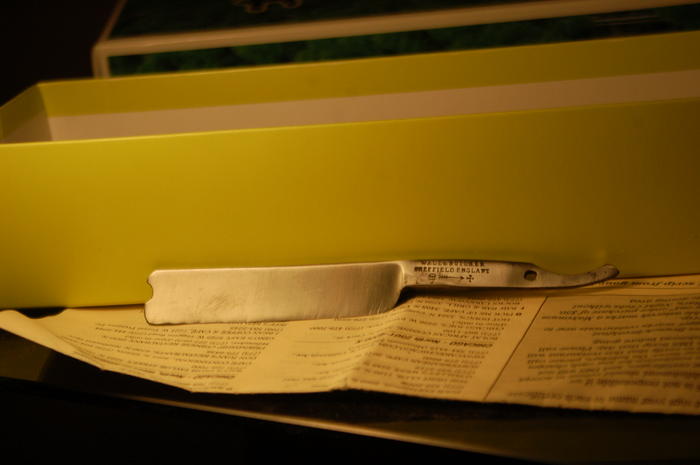

What you are trying to accomplish the hard way is a facial regrind,,, many of the older Sheffield wedges were re-ground after the turn of the century into Hollows so most likely you have the room but I would love to see a pic...

-

04-15-2011, 03:04 AM #3

heat better pay attention to it. if you change temper that blade will become useless.

gl

-

04-15-2011, 03:16 AM #4< Banned User >

- Join Date

- Mar 2011

- Location

- Chicago

- Posts

- 92

Thanked: 13

I put that grinding wheel on the blade and run it across, even pressure, real quick, and the blade never gets more than slightly warm. I'm gonna post a pic in a second here with my crappy camera, hopefully you can see the pitting...i went over it with 320 greaseless hoping that would finish it up, but theres still more pitting...

-

04-15-2011, 03:25 AM #5

I have found that the first rule of pitting is that it's probably deeper than you think it is.

-

04-15-2011, 03:28 AM #6< Banned User >

- Join Date

- Mar 2011

- Location

- Chicago

- Posts

- 92

Thanked: 13

-

04-15-2011, 03:31 AM #7< Banned User >

- Join Date

- Mar 2011

- Location

- Chicago

- Posts

- 92

Thanked: 13

holli, the eternal optimist

j/k but yes, take a little bit off the surface of the pit, and that equates to a lot of metal off the edge of the blade. Now, should I be grinding in equal amounts across the whole surface of the blade to maintain a flat, consistent face, or is it OK to isolate the grinding, and blend the deeper grinds in with the shallower ones? I'm used to working with wood in this capacity, not so much metal.

j/k but yes, take a little bit off the surface of the pit, and that equates to a lot of metal off the edge of the blade. Now, should I be grinding in equal amounts across the whole surface of the blade to maintain a flat, consistent face, or is it OK to isolate the grinding, and blend the deeper grinds in with the shallower ones? I'm used to working with wood in this capacity, not so much metal.

-

04-15-2011, 03:36 AM #8< Banned User >

- Join Date

- Mar 2011

- Location

- Chicago

- Posts

- 92

Thanked: 13

btw, just looking at your web page holli...did you really sell that 8/8 bengall for $35???(if so you should change your name here to santa claus

) Do you still have those razors in your archives, or are they sold?

) Do you still have those razors in your archives, or are they sold?

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote