Results 1 to 8 of 8

Thread: Have I brought a lemon?

-

05-03-2011, 03:53 AM #1

Have I brought a lemon?

Have I brought a lemon?

Hello.

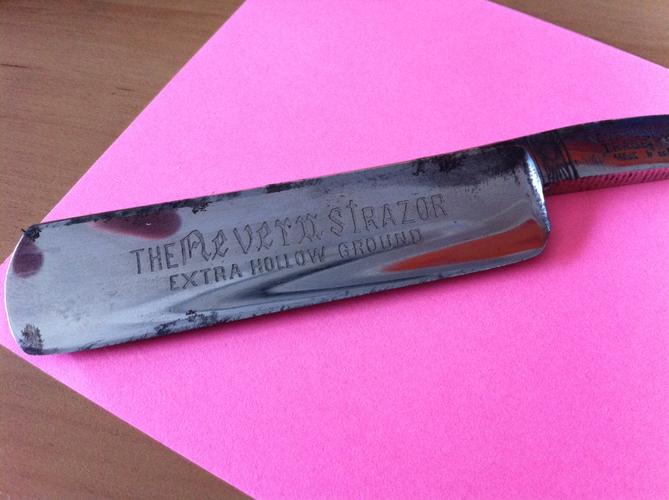

I just brought an old Razor from a local Antique Shop. It had larger than normal washers at the blade end & when I removed the broken scale I discovered that someone has previously drilled the hole bigger than standard. Am I a bit stuffed here? I love the blade shape and the engraving on the blade. One of the scales was broken but I figured I'd have a go at making new ones for the first time. Have I been suckered here? I paid the equivalent of about $30US.

-

05-03-2011, 04:06 AM #2

Looks a tad forlorn but I'd give it a go. Check out the posts on sleeving. You'll basically be putting a sleeve in that hole to reduce the size.

-

05-03-2011, 04:37 AM #3At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,196

- Blog Entries

- 1

Thanked: 13250

Let me give you a important hint about restorations,,, Before you do anything else make sure that razor can take an edge...

You need

325-1000k Stone /Hone/Plate

A good magnifying glass or loupe

Do 20-50 laps using a bit of pressure to cut away that crud at the edge and then look at the edge under magnification and a good light if the edge is full of swiss cheese looking holes repeat and try again, if you cant find solid clean steel, doing a restore is a waste of time...

-

-

05-03-2011, 04:43 AM #4illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

I agree with Glen, but I think you're going to come out with a good edge. After all, it'll never rust! Now, does that thing look chrome plated to anyone else?

-

05-03-2011, 05:04 AM #5< Banned User >

- Join Date

- Jan 2011

- Posts

- 134

Thanked: 21

-

05-03-2011, 05:11 AM #6

When I get home from work I'm going to give it a polish with some Autosol. Just to see what I can.

-

05-03-2011, 07:39 AM #7

That oversized hole can be filled up, eazy-peazy.

Find a length of brass rod which will just slide down into the hole. Cut this off only very slightly longer than needed (about 0.5 - 1.0 mm extra).

Insert this bit of brass rod into the hole and start peening lightly (working from both sides) to expand it so that the brass will expand into the hole.

Once it is as secure as can be, carefully file away any bit of the brass which stands proud of the surface. I suggest using a very fine cut file with light strokes.

Once this process is complete, you need only redrill the correct size of hole for the rivet pin you plan to use.

If you are at all in doubt, you could also use some quick set epoxy when you insert that bit of brass prior to the peening, but I haven't found this to be necessary.

-

The Following User Says Thank You to ignatz For This Useful Post:

jahaworth (05-03-2011)

-

05-03-2011, 03:17 PM #8

I've found that on some of the my older restore razors that the pivot hole is usually larger than 1/16". I went down to my local hardware store and picked up a length of 3/32" brass tubing. Usually this will fit into the hole although, on a few occasions I've found that I've had to increase the diameter just a tad with my drill press. Once the tubing fits in, just cut off a piece and file it until it's flush on both sides of the tang. Now, you got a sleeve that your 1/16" pins will fit into.

-

The Following User Says Thank You to Rusty Shackleford For This Useful Post:

jahaworth (05-05-2011)

3Likes

3Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote