Results 1 to 8 of 8

Thread: making new scales, advice needed

-

06-06-2011, 01:38 PM #1Member

- Join Date

- Apr 2010

- Posts

- 51

Thanked: 3 making new scales, advice needed

making new scales, advice needed

so I am working through my collection and decided how to go about my restoration process. I have 12 scale sets that I am going to have to replace.

I have seen where I can buy rare wood blanks, plastics, even kevlar for scales. I am just curious what everyone else is using to replace scales these days... If you are using wood, please feel free to tell me the type and anything you used to enhance the wood's colors.

I will start to post pics of my scales as they start to come along.

-

06-06-2011, 01:39 PM #2Member

- Join Date

- Apr 2010

- Posts

- 51

Thanked: 3

oh, and is there anything you can do with old scales besides toss them?

-

06-06-2011, 04:14 PM #3aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Hang on to the old scales & wedges as they can be used as patterns and such. As far as what is being used...everything from horn to ivory to linen micarta and on and on. Start with 1/8" thickness and choose your interest. If you use woods you might consider the more oily type woods like cocobolo or african ebony wood. Use a mask when making pretty much any scales as much of the material is a lung irritant.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

06-06-2011, 04:16 PM #4

Save them for future templates and inspiration. Maybe cut them up for wedges if particularly interesting material.

As far as what is popular, as you mentioned plus horn, bone, g10/micarta, acrylics. Take a look at knife supply places like masecraftsupply.com, texasknife.com, alphaknifesupply.com to name a couple.

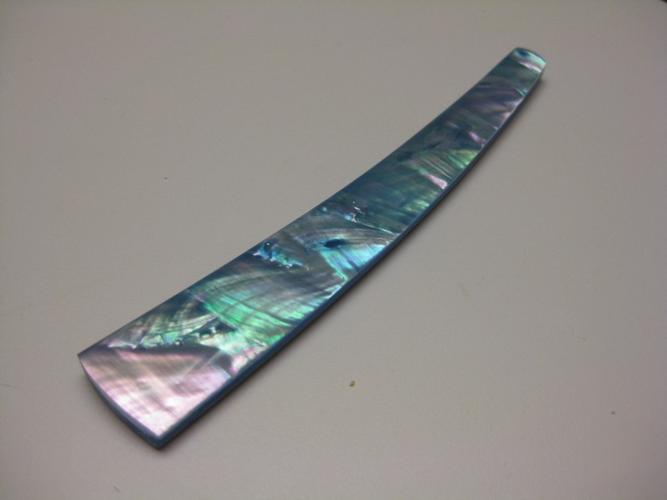

As far as unpopular materials, most anything 1/8" thick strong yet flexible can be used. Lately I've been composing my own material, playing with shell and shell veneer. This fuzzy, progress pic is Donkey Ear Shell, aka sea snail, veneer over 1/64" g10 as liners. Clear coated with epoxy resin.

Last edited by dirtychrome; 06-06-2011 at 04:28 PM.

-

06-06-2011, 04:30 PM #5At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,052

- Blog Entries

- 1

Thanked: 13249

Everything said above with one warning

Watch the length of the material at Knife and Pen places they use mostly 5 inch long stuff, this will NOT work for us, if it doesn't give an actual size you can almost bet it is 5 inch... You need 6 x 1 x 1/8 inches for minimum dimensions to work with, yes the scales are smaller when done,but you will find that this is a perfect minimum target size...

-

The Following User Says Thank You to gssixgun For This Useful Post:

Str8Raz0r (06-09-2011)

-

06-06-2011, 05:44 PM #6

My preference would always be for something available when the razor was new, or at least hard to tell from it visually.

Remember that if you can get an exotic wood you like, anybody with a bandsaw can cut a few 1/8in. slices in minutes. Not many stabilised woods are available in razor lengths, but you can come pretty close by impregnating and coating them with the most liquid grade of cyanoacrylate superglue.

Most woods will darken with exposure to light, no matter with what they are coated. Of course if ebony darkens you can say "Ya boo, see if I care," and some very pale woods may actually benefit.

When woods are stabilised by impregnation, the first stage is often reducing the pressure below atmospheric. The idea is that you aren't forcing the stuff in, at first, but sucking out any air in the pores. If you want to impregnate the wood with linseed oil, cellulose sealer, melted wax etc. you can get a somewhat weak version of this effect by heating the substance with some air below a loosened lid, then tighten the lid and let it cool. Heating should be with a large vat of very hot water, rather than a flame, if the substance is volatile or flammable.

-

06-06-2011, 06:30 PM #7

-

06-07-2011, 04:58 PM #8

I'll cut up some nice wood for you if you would like to go that route. Drop me a line and I'll pick a few of my favorites.

Phillip

5Likes

5Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote