Results 1 to 10 of 14

Hybrid View

-

07-28-2011, 09:55 PM #1

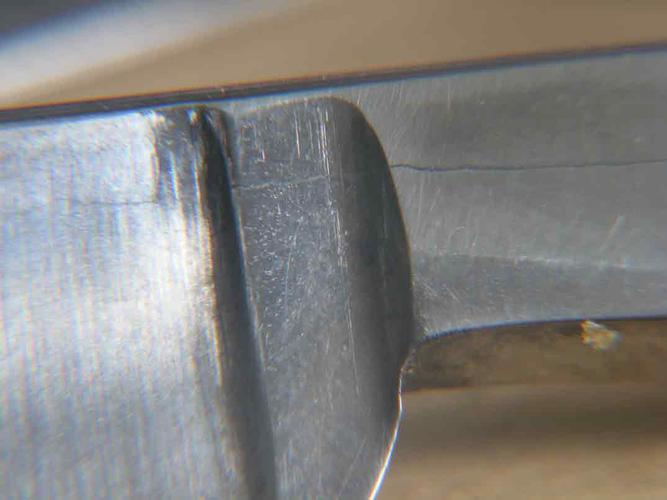

Anyone seen anything like this before? Cracked tang.

Anyone seen anything like this before? Cracked tang.

Pulled an ebay Triumph out of the mailbox today and found a hell of a weird (to me, at least) crack running lengthwise through the tang and shoulder. How does something like that even happen? Thermal effects?

Crack doesn't go all the way through. Can't see it affecting anything important, just a bit surprised and thought I'd share.

-

07-28-2011, 10:00 PM #2

I've never seen that. Does it show on the opposite side as well ? If it extends to the pivot hole perhaps it may have been punched rather than drilled and the force of the press may have done it.

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

07-28-2011, 10:14 PM #3

-

07-28-2011, 10:19 PM #4

Only speculation on my part, but I think the tang stamp may have revealed a fault in the steel. Probably got passed quality control unseen and will shave fine.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

07-29-2011, 12:28 AM #5"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

It could also be what's called a "cold shut". This is a forging defect where the steel folds across or around itself without a weld to make everything homogenous. A crack from driving the pin hole should show up on both sides. There is no way to determine when this happened. It could have been the steel mill, or the razor manufacturer.

I agree with Jimmy, it is a non-fatal flaw, it should shave just fine. Keep it oiled to prevent future issues.“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

-

07-29-2011, 12:39 AM #6

I've seen a few of those during the years. Nothing that prohibited the razor from functioning normal.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote