Results 1 to 9 of 9

Thread: Sanding out scratches

-

09-16-2006, 12:24 AM #1Junior Member

- Join Date

- Jul 2006

- Location

- Raleigh, NC, U.S.A.

- Posts

- 13

Thanked: 0 Sanding out scratches

Sanding out scratches

I was going to make this a long story, but I donít think anyone really wants to hear (read) it. Short version: I found a Geneva 5/8 at a flea market, with good condition box for $12.

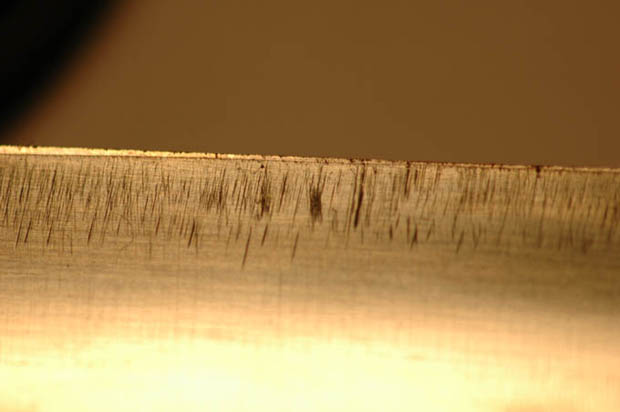

This is original condition.

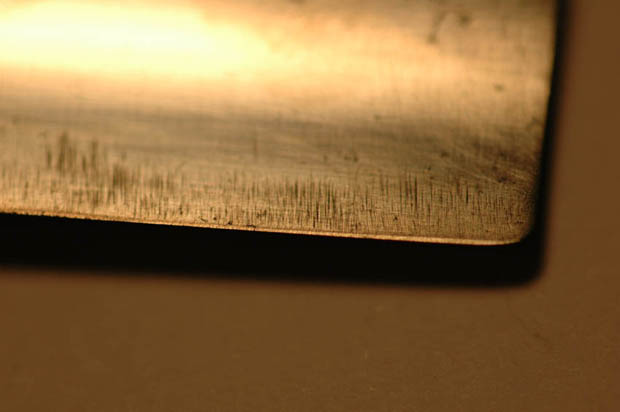

This is original condition.

Everything about it is good (scales look like they have never been out of the box, no pitting, one small stain on the spine, point end) except it looks as if someone put it on a grinding wheel. The scrapes are not deep, and do not affect the bevel, but I would like to get them out.

I have a Dremel, Billís CD, and the willingness to work, but am not sure if I should try to sand the scratches out parallel to the scratches (perpendicular to the edge) or perpendicular to the scratches (parallel to the edge). I donít care about a mirror finish, because I actually prefer brushed or satin finishes. Should I start with a 400 grit paper, or higher grit? I already hit it a bit (manually) with 1200 grit Norton wet/dry paper just to see if that would do it, but obviously not.

Anyone have any advice? Thanks guys.

-

09-16-2006, 01:22 AM #2

Look up the thread on the flap wheels that I posted. They alone will give you a satin finish. You can go finer, but look up Jason's thread on Dremel drums first. It will save you lots of elbow grease.

-

09-16-2006, 01:37 AM #3

Polish across the scratches to remove them - parallel would continue to cut them.

-

09-16-2006, 01:48 AM #4Junior Member

- Join Date

- Jul 2006

- Location

- Raleigh, NC, U.S.A.

- Posts

- 13

Thanked: 0

whoosh! just as I was going to ask Firestart about the across/with sanding, Tombuesing's message appeared. Strange.

Thanks both of you. I appreciate it.

Firestart, I had read your flapwheel review when you first posted it. I was planning on picking some up, or at least looking for them in town here, when I did my errand tomorrow. And I found Toxik's dremel drum instructions. Great!

Now, should I start with a finer grit paper just to see if it works (say 400)? And if it doesn't, then move to coarser grit for a bit and then back up to a finer grit?

I'm just trying to avoid doing too much damage the other way, when I am trying to clean the blade up.

Last edited by Gaelicboy; 09-16-2006 at 01:51 AM.

-

09-16-2006, 04:09 AM #5

The flap-wheels are good at fixing up the surface without removing too much metal. I've done some resurfacing on very delicate grinds. It will be quicker and easier if you start with 120, move to 240 and then 400.

-

09-16-2006, 05:56 AM #6< Banned User >

- Join Date

- May 2005

- Posts

- 1,304

Thanked: 1

If you are going to do it by hand and you sand perpendicular to the offensive scratches, you will be able to tell when they are gone. Once you get close to the point where they are gone, you can go to the next higher grit of wet/dry paper.

Start with 220, then 400, and then 600. Once you have reached 600 and show no more scratches, you can put the "factory" brush finish back on by working perpendicular to the edge again either with sandpaper, scotch brite wheels, the radial bristle discs I suggest on my CD, or the flap or drum wheels that have been suggested here on this thread.

The best look will come from the radial bristle discs. 4 of the yellow on one mandrel at about 8,000 rpm. riogrande.com

If you have the newer version of my CD, the answer is in the video section called "The Buffer"

-

09-16-2006, 11:27 AM #7Junior Member

- Join Date

- Jul 2006

- Location

- Raleigh, NC, U.S.A.

- Posts

- 13

Thanked: 0

Thanks all. Good info.

Bill, a quick question about Rio Grande. I went to their website when I first received your CD, and the only way I could access anything (even looking at products) was to log on to their secure system. In order to get a login/password, you needed to have a customer number and a previous invoice number (or $ amount).

Do you need to request a catalog, and mailorder from them first, before accessing their web site? I apologize if this has been covered in another post.

Thanks.

edit: I stopped being a dummy and found the help section on the riogrande site.

Quote from the "why" portion of Riogrande : "The jewelry business presents security challenges that do not exist in other businesses. Due to those security concerns, we take extra precautions when establishing new customers. We also want to ensure that we are selling supplies to jewelers, jewelry retailers, manufacturers, designers, jewelry students, and others who require jewelry supplies for their business. Rio Grande does not serve jewelry-buying consumers.

In order to protect our company and our customers we initiate all new accounts with one of our direct sales representatives. After you have established your account and placed an order with us, you will be able to use our website for future purchases."

new orders have to be over the phone first.

-

09-16-2006, 02:49 PM #8< Banned User >

- Join Date

- May 2005

- Posts

- 1,304

Thanked: 1

Tell them that you are trying your hand at manufacturing razor scales that require small hand tools. I don't know that they have ever refused anyone yet for this stuff.

They have a lot of jewelry stuff that is real cheap and is already finished. I think they are trying to avoid the person trying to resell on eBay or something.

-

09-17-2006, 10:21 AM #9

Bill, I just got my catalog from Reo and called. They asked me what part of the jewelry buisness I was in. I told them I was refinishing straight razors. They called that a "craftsman" and gave me authorization. I have been ordering from them every since. Great company. Love their stuff.

Bill, I just got my catalog from Reo and called. They asked me what part of the jewelry buisness I was in. I told them I was refinishing straight razors. They called that a "craftsman" and gave me authorization. I have been ordering from them every since. Great company. Love their stuff. Originally Posted by urleebird

Originally Posted by urleebird

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote