Results 1 to 10 of 13

Thread: Work in Progress Pics

-

12-16-2011, 11:09 AM #1

Work in Progress Pics

Work in Progress Pics

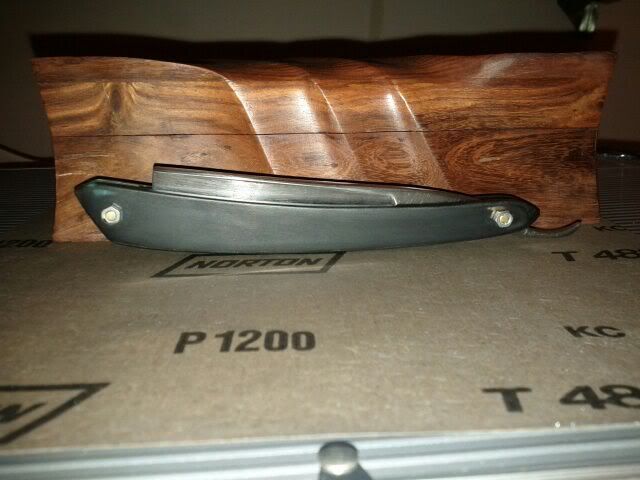

Thought I'd post a few WIP pics of my first re-scale.

A few ideas being tested out with this one!

Scales are clear polycarbonate, which I though was acrylic. This is why they will become black eventually, as the polycarb scratches if you look at it It's just a black enamel in a rubbed down inter-coat state!

It's just a black enamel in a rubbed down inter-coat state!

Spacer is a laminate of various plastics, I also have an Aluminium / Rubber laminate of my own manufacture to try out.

Pins are not pins at all, I have tapped a Brass rod to M3 thread, Nuts are A2 Stainless

Also trying out brass washers as bushings - this works really well!

Razor is a Joseph Allen, I think I've posted it here before in its original leather scales

Anyway - pics!

-

12-16-2011, 03:03 PM #2

I can't see the razor... I'm too busy staring at that beautiful box behind it. Did you build that?

-

12-16-2011, 05:50 PM #3

No, I'm afraid I didn't build that, bought it in from India!

-

12-16-2011, 06:01 PM #4

Darn I'd love to hear how they built it. At first I was thinking a lathe of a large block, but I don't think they could do the angled swirl that way. Now I'm thinking they simply hand carved the block before slicing the lid off. Hmm going to loose sleep over this one! Well it's a very nice box you're lucky to have.

P.S. Those nuts are cheating! No fair. Get out your hammer!

-

The Following User Says Thank You to RobertH For This Useful Post:

PaddyX21 (12-16-2011)

-

12-20-2011, 04:31 AM #5aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

PaddyX21 (12-20-2011)

-

12-20-2011, 07:58 AM #6

Okay okay I'll give pinning a go lol!

Need to source some narrower gauge brass rod than M3 though really

-

12-20-2011, 02:21 PM #7aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

I buy my brass rod at Hobby Lobby. I have heard of some guys buying nickle/silver at welding shops.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

12-21-2011, 12:08 PM #8

Thanks, I'm finding the rod fairly easy to find, but washers without an enormous OD I'm finding more difficult, anyone have a lead for a UK supplier?

-

12-22-2011, 09:44 PM #9

-

12-24-2011, 07:06 PM #10

I like the shape.

Advice on your wedge. It isn't flat on the sides, they bow outward in the middle of the wedge. Having perfectly flat wedge sides and perfectly flat insides of scales will make the wedge fit much better. To accomplish this, run your wedge back and forth on both sides on a file or sandpaper on a marble/ceramic tile. It has to be flat, otherwise you get the gaps like your razor has. I still struggle with this, but I'm getting better. Absolutely flat is the key.

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote