Results 1 to 10 of 23

Thread: My new setup

Hybrid View

-

12-29-2011, 08:17 PM #1

My new setup

My new setup

Yes, I know most of you have seen the same or similar before, and many of you have a similar setup in your workshop, and some of you really couldn't care less of what I got in my workshop, but I'm still going to post this 'cause I'm kinda proud of what I got set up and wanted to share with you guys

I got some money for my birthday and x-mas so that I could go out and get what I needed (read: wanted) for my workshop.

Here's what I got:

- A simple drill press, designed for a redular hand drill, but with a little modification one of my "Dremels" (Cheap copy thats at least as good as my "real" Dreamel) fitted perfectly.

I was looking at the bech press for Dremel, but this one was 1/5 of the cost and more solid

- 16" Scroll saw.

- Belt/Disc sander w/40, 100 and 180 belts.

Now I only need to get a buffer, and that have turned out to not be as easy as I thought up here.

I can get felt and cotton wheels for bech grinders easy enough, but all I can find is polishing compound, and all of the grinders I have looked at runs at 2800 rpm or more.

Looks like I'm stuck with hand sanding for a while

Anyway, here's a pic of my workbench:

Need help or tutoring? Check out the .

Need help or tutoring? Check out the .

Rune

-

12-29-2011, 08:28 PM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,204

- Blog Entries

- 1

Thanked: 13250

Nice !!!!

BTW on buffers the RPM is only half the equation the whole equation is what is called surface speed I will look for the thread that explains it better, but basically you can just use a smaller wheel to compensate for a faster motor

Will post a link as soon as I find it in the workshop sticky

This is a good read and has the calculations for Surface speed (SFPM = 1/4 x diameter of Wheel x RPM (revs of spindle per min.)

http://www.caswellplating.com/buffs/buffman.htmLast edited by gssixgun; 12-29-2011 at 08:43 PM.

-

12-29-2011, 09:22 PM #3

Thanks Glen,

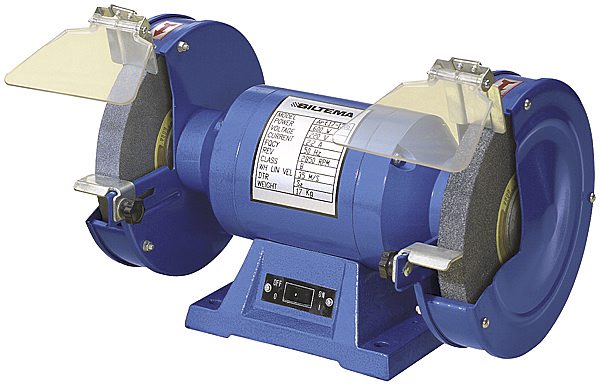

I've found a grinder that runs on 2850 rpm with 6" wheels, so if I understand this correct that would make 1,5 x 2850 = 4275 SFPM, which should work okay?

If so, finding the right compounds is my next challenge, the "problem" being here is that I have no freaking clue what it is called in Norwegian

Here's the grinder and discs I've looked at:

Need help or tutoring? Check out the .

Need help or tutoring? Check out the .

Rune

-

12-29-2011, 09:56 PM #4At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,204

- Blog Entries

- 1

Thanked: 13250

If it were me I would target 4 inch wheels to keep the SFPM down even more I run 3450 rpm at 4 inches and I take my time

-

12-29-2011, 10:30 PM #5

Smalles grinder I've found is a 5" that runs 2900 rpm, and the 6" wheels are the only one I have found so far, but the wheels I could order from abroad, guess they're neither expencive nor heavy.

I actually found a store in Norway that carries buffer compound in 120, 180, 240 and 320 grit.

What do you recommend for "regular" restoration? I guess I won't need all?Need help or tutoring? Check out the .

Rune

-

12-29-2011, 10:50 PM #6At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,204

- Blog Entries

- 1

Thanked: 13250

Here first

it really is named correctly hehehehe

it really is named correctly hehehehe

http://straightrazorpalace.com/works...wers-here.html

then in the middle

http://straightrazorpalace.com/works...compounds.html

http://straightrazorpalace.com/works...lustrated.html

http://straightrazorpalace.com/works...ials-info.html

-

-

04-18-2012, 08:50 PM #7

Fint! I wish i had some space in my tiny Home and didnt have to work on the kitchen table. Nice setup!

-

The Following User Says Thank You to Frameback For This Useful Post:

Zephyr (04-18-2012)

-

04-18-2012, 10:13 PM #8

I like it!! Good set Up!!

-

04-18-2012, 10:24 PM #9

Very nice Rune!!

So, basically, you now have two places in your home to tinker with straights..

I like it!

-

The Following User Says Thank You to Birnando For This Useful Post:

Zephyr (04-19-2012)

-

04-18-2012, 10:36 PM #10Member

- Join Date

- Nov 2006

- Location

- Norway

- Posts

- 32

Thanked: 3

Looking very good, nice set up

-

The Following User Says Thank You to Terje K For This Useful Post:

Zephyr (04-19-2012)

19Likes

19Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote