Results 1 to 7 of 7

Thread: Sand blast

-

01-04-2012, 01:16 AM #1

Sand blast

Sand blast

Has anyone thought of a light sandblast to frost a blade? I have a old pitted Wade & Butcher blade that has some rust and pitting. I figured I could wet sand out the pitting and then frost the blade itself with a light sandblast and then high polish the spine and shank.

-

01-04-2012, 02:35 AM #2Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Have bead blasted a few in the past,they look like hell IMO,just sayin

-

01-04-2012, 02:55 AM #3

I think a technique would need to be developed, practiced and applied. I think it could work. With glass beads and proper application, distance, taping, etc.

Doesn't cost much to try! I have seen many artists work it with glass!"Don't be stubborn. You are missing out."

I rest my case.

-

01-04-2012, 03:14 AM #4

I have worked with a tiny jewelers bead blaster before. Its about the size of an air brush. I think it would work, but caution would have to be used close to the edge. Also to maintain the frosted look one would have to tape the spine when honing, unless you wanted a polished edge and spine. There is a paint on latex you could use for masking.... Just kicking some ideas.

Enjoy.

-

01-04-2012, 03:33 AM #5

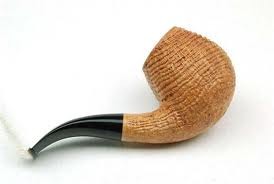

Yeah, I think you could even with liquid masking do an etching effect. Maybe a small sandblaster loaded with a fine talcum medium. I use a similar thing when I sandblast tobacco pipes

*example* not one of mine but

You get the idea

-

01-04-2012, 08:07 AM #6

You will never know till you try. Just use a scrap chunk to practice on and get your grit size, air pressure, distance and surface finish (pre glass bead) to a point you like. Your finish before can make a difference after.

Jeff

P.S. There are numerous types of blast media.

-

01-04-2012, 09:45 AM #7

I was wondering what you guys were talking about, because I had only heard of the common frosting effect

applied to glass or translucent acrylic... and pneumatic blasting used for nothing more than material removal.

-But I stumbled across this manky razor, and I'm guessing this etching technique is what you're referring to?

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote