Results 1 to 10 of 24

Threaded View

-

01-30-2012, 07:36 AM #1At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,165

- Blog Entries

- 1

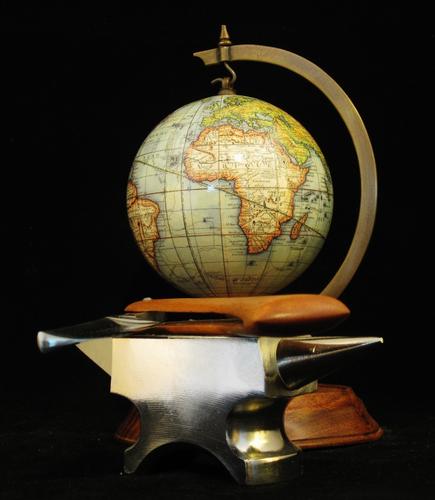

Thanked: 13249 One Piece Scales - Problems and Solutions

One Piece Scales - Problems and Solutions

So after making my first set of one piece scales

I was working through a set today for a rather large tanged W&B this one has a nearly 1/4 inch thick tang so now the problems with a set of one piece scales rises it's ugly head...

I looked through SRP and found that the problem has come up before with some solutions

1. Cut the slot at two angles to create the "flair" at the pivot end

2. Use wider material and a wider Kerf blade to cut the razor slot

3. Use a band saw and cut the "flair" into the scales.

Although these solutions can work they leave me wanting a neater cleaner look

So how to create a flair like from a wedge yet not have the ability to make the wedge

I wanted a nice even straight cut with equal thickness on the sides of the scales, so this is my solution to the problem..

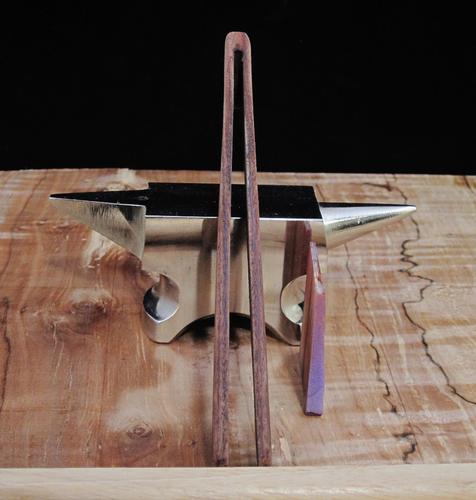

I put in a wedge sorta

sorta

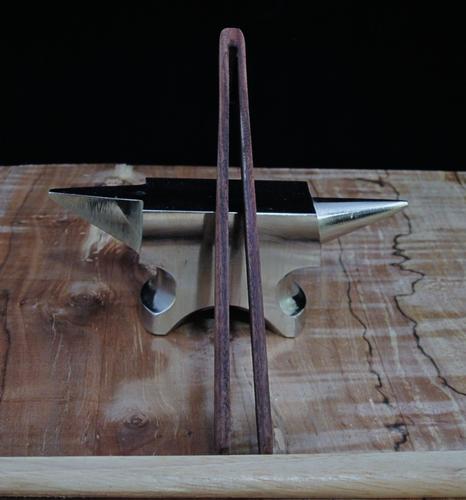

I made a wedge out of acrylic, after the scales were shaped, sanded, and cut, so basically they would be ready for a smaller tanged razor, but with out the coats of final finish.. I pushed the wedge down into the razor slot as far as I could, it was about 1 inch shy of the end.. I took this and placed it over a boiling pot of water on top on a splatter screen so it was right in the steam.. After about 3 minutes I pushed the wedge deeper, and put it back in the steam, another 3 minutes and the wedge hit bottom... I left the whole thing in the steam for about 5 more minutes, I let it cool completely and this is where I am at now.. It looks like steam shaping might be working.

The flair is there just like a two piece set of scales, I'll put it all together tomorrow and see how the fit works...

Hopefully the flair will stay "set" in the wood to create a bowed effect that I am after.Last edited by gssixgun; 01-30-2012 at 03:58 PM.

-

The Following 9 Users Say Thank You to gssixgun For This Useful Post:

BKratchmer (01-31-2012), cudarunner (07-18-2012), DoughBoy68 (12-12-2020), Laurens (03-21-2013), lz6 (01-31-2012), RayCover (01-31-2012), ScottGoodman (01-30-2012), skipnord (03-21-2013), WillN (02-02-2012)

26Likes

26Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote