Results 1 to 7 of 7

Thread: Blade Experiment

-

02-25-2012, 10:00 PM #1

Blade Experiment

Blade Experiment

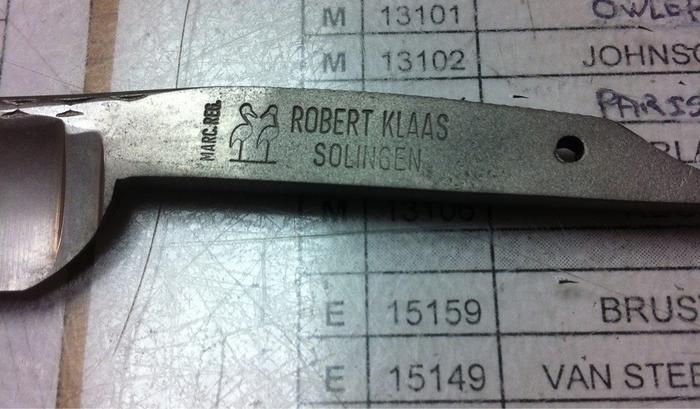

I had sent this Robert Klaas blade out to be honed but rust and pitting it made it impossible for the honemiester to get a good bevel without micro chipping. So it made an excellent test bed. I decided to see if I could frost the finish. So I set the sandblaster up at work and it worked like a charm. This did not remove pitting but it sure made it obvious. So now I'm going to sand out the pitting and see if I can reprofile the blade and make it shave once again.

Before:

After:

-

02-26-2012, 12:44 AM #2

Update:

I sanded from 80 to 320 grit. I managed to get all the pits out. I then bread knifed the frown out of the blade. My goal here is to frost just the grind and have the rest a mirror finish. So we shall see how this goes. Oh yeah! Here are the pics of the blade at 320 grit

-

02-26-2012, 03:12 AM #3Member

- Join Date

- Feb 2012

- Location

- Ann Arbor, Michigan, United States

- Posts

- 74

Thanked: 16

I like the idea. You will have to make another with a mirror grind and everything else frosted.

-

02-26-2012, 03:30 AM #4

Lol maybe so. Now you have me wondering which way would look better????

-

02-26-2012, 10:03 AM #5

IMO I would frost the tang and make the blade a mirror finish.

-

02-26-2012, 10:52 PM #6

Update: well here is the blade before final buff. I am really leaning towards frosting just the grind and leaving the shank and spine mirror finish. What do you guys think?

-

02-28-2012, 03:19 PM #7

* UPDATE*

The blade was finish sanded and buffed. I took a good look at it and decided not to frost any part of it. So I made up a set of scales with a horn spacer and finished them in a CA finish. Only problem is I won't use horn again as a spacer as its variable coloring makes the wedge look like its cracked in places. But it's not! So I left it rather than un pin the whole damn thing. Well anyhow here are the pics

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote