Results 1 to 9 of 9

11Likes

11Likes

Thread: Redneck Resawing Scale Blanks (RRSB)

-

09-21-2012, 12:05 AM #1

Redneck Resawing Scale Blanks (RRSB)

Redneck Resawing Scale Blanks (RRSB)

About a month ago a member, mainaman, requested I post information on a subject I discussed in another topic. He wanted information and like all good SRP members, wanted pictures as well. So, for what it is worth, here is my two cents on how to resaw a scale blank to get double the material and sometimes rare gems from your purchases on eBay or elsewhere.

The candidate for this explanation is a piece of Eastern Red Cedar. It is one of a pair I bought on eBay. The blanks sure looked pretty in the online pictures but when I got the blanks, I was terribly disappointed. They looked so mundane I figured I'd use them for kindling. So I decided to use them for this demonstration instead. Here are the blanks:

The one on the left is today's candidate. Each blank is 3/8" thick. Plenty of material considering the miter saw blade is only 1/32" thick.

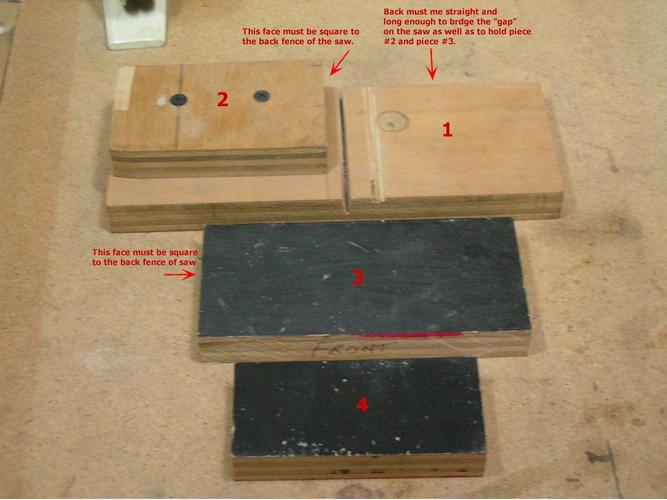

The jigs I use are seen below. They are 4 pieces of scrap plywood I had lying around and slapped them together to make a jig.

Piece #1 is necessary to span the gap in the saw deck as you will see later. It needs to be long enough to bridge that gap and also hold pieces #2 and #3. Piece #2 is the left guide for the blank and piece #3 is the right guide. The faces of #2 and #3 need to be square with the back fence. The guides not only align the scale scale blank for centering but are also clamped securely against the blank to hold it firmly in place. Piece #4 is to be used on the back of the saw fence to keep the blank from slipping through the gap as you saw. You'll understand soon as I post more pictures.

The saw I use is a Stanley 20-800 Contractor Grade Mitre Saw. It sells for $40 on Amazon and got fairly bad reviews. I've had mine for years and have been completely satisfied with its performance. Anyone who thinks they will get a "perfect" angle cut with any miter saw is kidding themselves. That's why I have a Miter Trimmer Guillotine [FONT=verdana][COLOR=#000000]that shaves a piece of wood thin enough you can see light through it. But we are not mitering. We are resawing and as in horseshoes, close is good enough. It gives a clean cut that needs almost no sanding. Notice the "gap" and "back fence" referenced previously.

Why use this instead of a band saw? First, not everyone owns a band saw. I do but still use this method. I do not like working so close to the blade on a band saw with such small pieces of wood and I get a perfectly smooth cut. Second, it works. What more need I say?

Okay, now it is time to put the pieces together and get down to the nitty-gritty of cutting the blanks. The next picture shows how to clamp everything together. See how the clamp on piece #4 allows just a small bit of the wood to project into the opening to hold the blank from sliding forward but does not get in the way of the cut? Actually, you will need to remove all the clamps except the ones holding the saw to the table top before mounting the saw blade so you can center the blade on the blank. Once centered, replace the clamps and secure them tightly. You WILL NOT get the blank perfectly centered! This is a given. But be as precise as you can. With 3/8" material and 1/32" blade, you have leeway. All you need as a finished product is a little over 1/8" that you can sand to the desired thickness.

The next picture is the resawing in progress. Depending on the height of the blank and density of the wood, the cutting should only take 3 to 5 minutes. Remember what what my Grand-pappy told me: let the saw do the work. Trying to put muscle into it will not do anything but cause binding of the blade. Your job is to guide the saw, not force it to cut. If the saw "sings" to you it is saying "easy" on the strokes. Chant that along with your sawing and you will get good results with a minimum of effort. (Sorry for the digression - I am primarily a wood worker and love the feel of good tools and the smell of fresh cut wood!) I am new to straight razors and trying to apply my skills from building a house or furniture to something infinitely smaller.

What started as a simple post turned out to be a wonderful discovery. Holy cow - the ugly duckling on the outside turned out to have a heart of gold inside!!

I think these just might make some beautiful scales:

What do you think?

Mainaman asked a specific question I'd like to address. He wanted to know if, instead of simply resawing a blank in half, you could use the same saw to cut slabs off of a larger board. Within the confines of the height and depth of the saw, the answer is yes. Take a board with the above limitations and cut off slices like salami to your heart's content. Not need for any jigs.

Okay, so you have your blank cut in halves. Now what do you do? They are different thicknesses and need to be sanded down to a uniform thickness with little or no tolerance for deviation. Spend hours sanding them by hand? Pay $1,500 to $6,000 dollars for a dedicated thickness sander? Go on YouTube and find a video how you can spend only $200 to make a thickness sander. Never fear my friends, the Redneck will be back with a simple and inexpensive ($5 to $20 depending what you have on hand) answer for your thickness sanding. You will have to have a drill press but I can imagine a true tinker who will find a way to use a simple hand drill to do the same thing. I will be posting my Redneck Thickness Sanding get-up soon.

Thanks for visiting,

Randy

P.S. I know "resaw" is spelled with a hyphen, i.e. "re-saw". But I figure if Shakespeare can invent something like 2000 words out of thin air that are now a part of our everyday language (hint, hurry, lonely, leapfrog, excellent and on and on) I can leave out a hyphen if I want.

For those who want measurements, remember I grabbed what was at hand from my scrap pile and threw it together. In fact I am now working on refining the jig so I get better and more consistent results. But here are what the bits and pieces I used measure: #1 - 10"L x 3"W; #2 - 4"L x 2 1/2"W; #3 - 5 1/2"L x 2 1/2"W; #4 - 4"L x 1 3/4"W.

Lastly, posting a Redneck method is time consuming so that is why they are not more consistent. What takes me minutes to accomplish in real time ends up being hours to post, Taking the pictures, sorting through the dozen pictures I took of each step to find just the right one to post, and annotating the pictures is no big deal. Adding maybe 30 to 45 minutes to the process, But I am a two finger typist, a bad speller and my fingers seem to hit the correct key the first time only about 70% of the time. This post started at around 5:00 and it is now 8:00. No sympathy wanted or needed. I love sharing if it actually helps someone else. Just explaining why the request for this post took a month for me to respond to. It takes that long for me to get up enough energy to go through the process. I promise though, the thickness sanding post will be coming very soon.

No sympathy wanted or needed. I love sharing if it actually helps someone else. Just explaining why the request for this post took a month for me to respond to. It takes that long for me to get up enough energy to go through the process. I promise though, the thickness sanding post will be coming very soon.

Whew!!! Finished!!!Last edited by WhiteLion; 09-21-2012 at 01:49 AM.

“Tell me and I forget. Teach me and I remember. Involve me and I learn.” Ben Franklin

-

The Following 16 Users Say Thank You to WhiteLion For This Useful Post:

adbuett (09-21-2012), AndyFranklin (09-24-2012), DwarvenChef (09-21-2012), Fenian (09-21-2012), Geezer (09-22-2012), Havachat45 (09-21-2012), Hirlau (09-21-2012), JimmyHAD (09-21-2012), mainaman (09-21-2012), parkerskouson (09-21-2012), pixelfixed (09-21-2012), skipnord (09-21-2012), spazola (09-21-2012), str8fencer (09-21-2012), TrilliumLT (09-21-2012), Zephyr (09-21-2012)

-

09-21-2012, 01:00 AM #2I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Great guide thanks a lot.

Stefan

-

09-21-2012, 01:10 AM #3"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Good use of that Armstrong saw too.

-

09-21-2012, 01:44 AM #4

Randy thanks for sharing this. Im going to do the same. Very Helpful.

-

09-21-2012, 02:53 AM #5

First - nice avatar.

Second - Excellent work.

Third - "The problem with defending the purity of the English language is that English is about as pure as a cribhouse whore. We don't just borrow words; on occasion, English has pursued other languages down alleyways to beat them unconscious and riffle their pockets for new vocabulary." - James Nicoll

-

09-21-2012, 03:07 AM #6

I could not stop laughing when I read your reply. A worthier and more apposite comment would be hard to find. Thank you for your comment and input. It really did give me a good hardy laugh which everyone needs now and again. Every time I read read it, I begin to chuckle again.

Randy“Tell me and I forget. Teach me and I remember. Involve me and I learn.” Ben Franklin

-

09-21-2012, 06:26 AM #7"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

-

09-21-2012, 02:28 PM #8

As I saw "redneck" in the title, I knew this was your thread, WhiteLion! Actually, that is the least redneck thing you have come up with yet! Great job!

Tom

-

09-21-2012, 03:44 PM #9Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Whitelion, Thank you for posting your work. Yesterday, I photographed the step by step process of degreasing an oil soaked eBay stone. OMG what a hassle. I will describe and post in a few days or weeks…

Having been a woodworker, hand tool collector and antique restorer, it is amazing that hundreds of years ago craftsmen produced amazing furniture by hand with less sophisticated tools and that furniture exist and in use today. I have all the latest power tools as well, but there is something, about the full sensory feedback from a handsaw or plane cleanly slicing, shaping wood and the satisfaction of a hand finished product.

Much like honing a hundred year old razor on an ancient piece of rock and producing an incredible shaving edge.

Thanks for sharing your ingenuity and your time.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote