Results 1 to 4 of 4

Thread: DIY Felt Buffing Wheels

-

01-04-2013, 10:44 PM #1Senior Member

- Join Date

- Apr 2012

- Location

- Jersey City

- Posts

- 225

Thanked: 50 DIY Felt Buffing Wheels

DIY Felt Buffing Wheels

So I was kicking around the idea of buffers but the problem is where to put it in the apartment. I wasn't happy with the end results with the Dremel and the Ryobi compounds. Streaks and and unevenness. And the small size of the pad kept it to close to the blade. It would slip off and ding the blade. If only the pads were big enough to keep it away from the blade. Dremel has felt pads but they're 1"x 1/16" and almost $3 a pop. What to do?

Make my own.

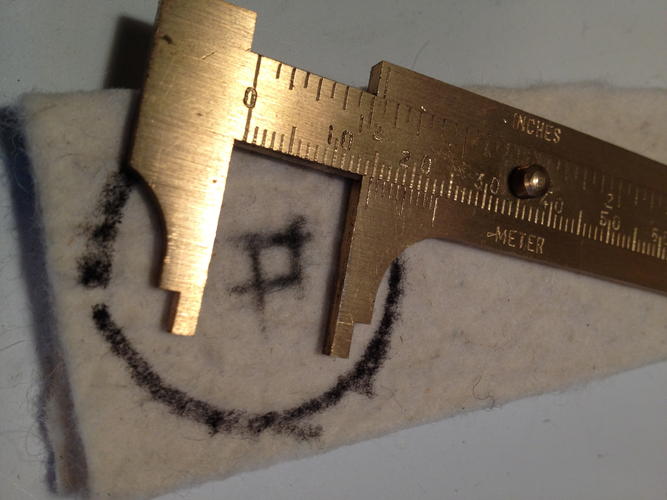

Found some left over felt (3/8") from my paddle strop station.

Using a 7/8" socket I marked out a circle that would be approx 1"OD.

Center would be about a 1/2" and marked that but it didn't need to need precise.

Trimmed to approx size but again, it didn't need to be precise. Poked a hole thru the center and worked the screw from a Dremel screw mandrel into the bit. The threaded mandrel didn't seen too work well.

Using the point of a sharp knife, turn the dremel on at a low speed and pushing the point downward, follow the outline of the circle. You'll pare away the excess felt like it was on a lathe. Wear eye proection!

Depending on your needs, you can have either a flat sided wheel or round. I was polishing smaller blades so I made this one rounded.

Works pretty well. If it bites, it's large enough that it misses the blade and it's the right size for hollow ground blades. It does generate heat so be careful. Keep a light touch.

The best part?

F-5 White Felt - 12" Wide

12"x12"x3x8"

$15.21

-

01-04-2013, 11:00 PM #2

Keep us posted on how it work out..also if you can share pictures of razors done this way would be great.

-

01-04-2013, 11:09 PM #3

I get my felt wheels from here. The best part? $15.97 for 36 pieces.

. If you do a search for FELT WHEEL other sizes and hardness show up.

. If you do a search for FELT WHEEL other sizes and hardness show up.

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

01-05-2013, 06:39 AM #4Senior Member

- Join Date

- Apr 2012

- Location

- Jersey City

- Posts

- 225

Thanked: 50

Hope I didn't give the impression this was a short cut to a restored blade or some new process. You still need to walk a blade up thru the grits and then polish. I was just trying to make some pads on the cheap and hopefully make the dremel a little safer to use.

In those regards, I think it was a success. Worked on an old Morley tonight. Started with an 80 grit flap wheel, then 120 grit flap wheel, EZ Lock abrasive wheels and then hand sanded up thru the grits but only to 600.

The smaller Dremel EZ Lock abrasive wheels were the most dangerous and I think it's because of the small diameter. When it bites, and they all bite, the distance between the arbor and the wheel is pretty small and it is the arbor that hits the blade. But when the larger felt 1" wheels that I made bite, there was enough distance between the arbor and the wheel that it never hit the blade.

I wonder if I could find a similar type material as the EZ Lock abrasive wheels and make larger wheels like the felt. Any help would be appreciated.

Tonight's efforts. It's not mirror but could be honed at this level. I'll probably sand it again up to 2k just to see how it turns out. Or maybe a spin in the tumbler with the corn cob just to see how it compares. Think walnut scales.

Need a lightbox.

Before

After

3Likes

3Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote