Results 1 to 10 of 17

Thread: Hot Pressed Horn Repair?

-

02-15-2013, 04:40 AM #1The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,737

Thanked: 481 Hot Pressed Horn Repair?

Hot Pressed Horn Repair?

So, if pressed horn is actually layers formed under heat and pressure, can scales that are delaminating be repaired using the same?

has anybody tried this yet?

-

02-15-2013, 06:07 PM #2The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,737

Thanked: 481

*cricket* *cricket* *cricket*

-

02-15-2013, 06:40 PM #3

I always thought it was just one piece of horn pressed into shape, and the delamination was caused by the natural layers of growth in the horn.

I find that when I straighten horn in my jig, it eventually works it way back to where it was... Maybe Im doing it wrong.

Curious to hear what others have to say!

Eric.

-

02-16-2013, 01:10 AM #4Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

Eric you are right - it is one layer of horn. The horn was boiled, the top cut off and the side split and then pressed flat. The it was split into layers of the required thickness, then hot-pressed.

It wasn't made like fibreglass or micarta - lots of layers laminated together.

So delamination is the breakdown of the natural layering in the horn, not the separation of many layers laminated together.

Magpie - possibly, yes. But the heat would have to be more intense than that used in making the scales. With increasing heat (wet heat) the horn breaks down so much it forms one plastic mass - but it then flows everywhere, and if in water it mixes with the water and becomes useless. Somehow you have to arrange to 'superheat' the horn - plain boiling water is not hot enough. Steam under pressure would be a better medium.

Regards,

Neil

-

02-16-2013, 01:40 AM #5

I had a piece of scrap horn lying around so I thought I would see if I could press a design into it with boiling it for long periods and using a vise. I was able to press a small design into the horn, but it wasn't nearly as deep as the older scales. Boiling the horn didn't get it hot enough to make it as pliable as needed. The design faded quickly once boiled again though. Also if I could put more force into the press with continued heat instead of just the vise with whatever strength I have it might have worked out. It was a fun experiment to see what could be done with stuff around the house. What some people will do when bored I guess.

Sorry I think I roamed off topic a bit there.Last edited by JSmith1983; 02-16-2013 at 01:48 AM.

-

02-16-2013, 02:31 AM #6The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,737

Thanked: 481

Alrighty, standard horn fix procedures then. But this WILL be something to try in the future!

-

02-16-2013, 04:07 PM #7

Forming horn

Forming horn

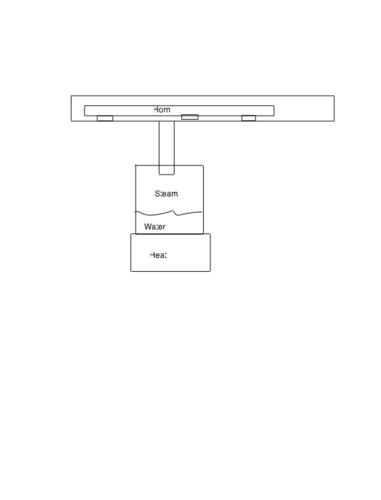

Perhaps you can shape the horn by steaming it in a box. When building a wooden boat you form the plank in a box with steam. You steam 1 hour/inch of thicknes. Then quick as hell you form the plank, and it settles to the shape you gave it. Of course the time to steam a piece of horn has to be significant shorter, and must be experimented out. 1 can, 1 box that is big enough to hold the horn slab, (as tight as possible) 1 pipe and a heat source is what you need.

Thats what you need. It might work, or maybe not. I can't see why it shouldn´t work.

Corrected: The box should be made of preferably wood. As epd pointed out you can get hurt by having it to airtight.Last edited by Ullmencott; 02-16-2013 at 05:31 PM.

-

02-16-2013, 05:16 PM #8

I suggest not building an airtight steambox. I had a serious steam/condensate burn when I was 18, not pleasant. If your going to play with steam, make a jig (seen in our wiki) and prop it over a large boiling pot.

I can only imagine the damage even a semi pressurized steam capsule would do to your face - worst case scenario.

Eric.

-

02-16-2013, 06:11 PM #9

IIRC, horn needs around 170-180 degrees celcius / 340-355f to be hot enough to heat shape properly. In the old days they would heat it on heated metal, still iirc. You would think it would scorch, but it doesn't at those temperatures.

There are videos on youtube, for those interested.

-

02-16-2013, 06:29 PM #10

Horn is built up in layers, if horn is subjected to water the soft layers in between the harder will leach out keratin and it will delaminate.

I know some people when boiling horn add keratin to the water to stop that, I don't know more about how they do it tho!Hur Svenska stålet biter kom låt oss pröfva på.

22Likes

22Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote