Results 1 to 10 of 45

Hybrid View

-

02-26-2013, 12:24 AM #1Junior Member

- Join Date

- Feb 2013

- Location

- Troutman NC

- Posts

- 18

Thanked: 2 Casting Scales from Silver Gold Brass etc.

Casting Scales from Silver Gold Brass etc.

Hey guys, I have built up a collection of Razors that need restoration, and I have been looking for materials to make the scales from. I am a metal fabricator by trade and it got me thinking about what I could do to make some scales from other materials besides wood and bone.

Then I remembered that a friend of mine who is (30+ years older than me) used to cast his own jewelry back when gold was 300 bucks an ounce instead of 1500 bucks like it is today.

We passed around the moonshine for awhile and came to the conclusion that we had everything that was required to cast scales from Gold, Sterling Silver, brass, or possibly other material.

Here is the first few steps in that process. Keep in mind that I know NOTHING about casting jewelry, but I am a quick study.

Step 1: Make the scales from Wax

Basically this involves getting some File-A-wax which is like candlewax but much harder. It is almost like plastic. Then drawing or carving the shape into the block. Just like making a scale from a blank.

The blanks are saw cut so I sanded them flat before I started. The blocks are designed for rings and jewelry so I had to weld two of them together which is nothing more than melting wax, sticking them together, and then letting it cool. I used a butane lighter.

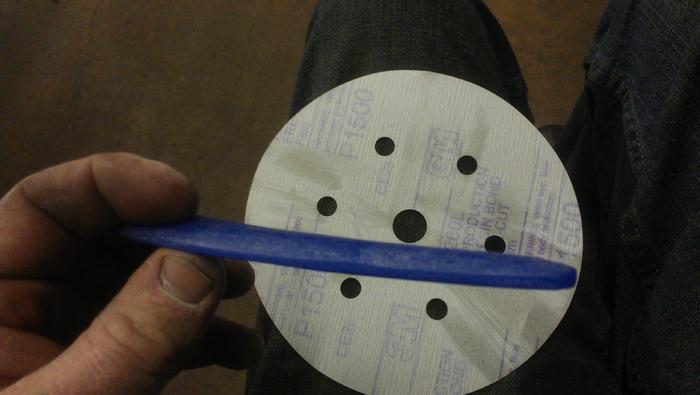

I used my airsaw to rough out the shape and then used the belt sander to fine tune it. Then I used my 3" DA sander to shape the sides. I started out with 40 grit paper and worked it up to 320. It still had scratches but I plan on polishing out any imperfections after it is cast.

I might have forgotten to mention that I am shaping both sides from a single piece of wax. I am not using a wedge pin and I am casting the wedge along with the rest of the scales. The hardest part was making the slot where the blade will rest. I did it with a steady hand and a Small jet band saw that can be vertical or horizontal. This might be easier with a scroll saw. But the band saw blade needs to be wide enough to accomodate the razor blade. OR just go the traditional route and build the scales in two pieces.

There was a little more sanding and some cleaning up of edges and sanding between the scales...but at this point the whole thing is very delicate. Each scale is about 3/32 thick. But the great thing about wax is that you can weld it back together if you break it or add material to cover imperfections.

Continued on next post.....

-

The Following User Says Thank You to doublev23 For This Useful Post:

Adam G. (02-26-2013)

-

02-26-2013, 12:28 AM #2Junior Member

- Join Date

- Feb 2013

- Location

- Troutman NC

- Posts

- 18

Thanked: 2

Here is an idea of what the finished product will look like, I have several blades to choose from but this is a Geneva Cutlery. That is in good shape.

I am thinking I will do this first one in sterling silver (gold is too expensive and brass is just cheesy) Then maybe get into some fancy designs or inscriptions in the scales later....if it all works out.

I am going to try to cast it this weekend....apparently it takes about 6 hours.

-

02-26-2013, 12:47 AM #3Senior Member

- Join Date

- Dec 2011

- Location

- I'm Gonna Spend Another Fall In Philadelphia

- Posts

- 2,029

Thanked: 498

Investment casting of scales. Very cool, very clever.

Good Luck.

-

02-26-2013, 12:53 AM #4

That is SUPER COOL! Hope it turns out for you!

-

02-26-2013, 01:11 AM #5Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Interesting stuff,wgt might be a concern tho,I remember when gold was $32 an ounce

-

02-26-2013, 01:20 AM #6Junior Member

- Join Date

- Feb 2013

- Location

- Troutman NC

- Posts

- 18

Thanked: 2

I thought the same thing about the wieght. But I am not good enough at shaving to know the difference. It will never be as light as wood but all I can do is give it a shot. I was thinking I could do some engraving to get the weight down and experiment to see how thin I could get the scales. Or do a skeleton scale where you could see the razor through the side. We will see I guess.

-

02-26-2013, 01:25 AM #7

Very good idea. Im iterested in seeing how this pans out.

-

02-26-2013, 01:45 AM #8

Very cool, I guess you cast that into clay, gypsum or ? Then pour the silver to take the place of the wax?

Im very intersted, I have a 150 grams of silver to play with..

Please keep us posted!

Eric

-

02-26-2013, 02:14 AM #9

Will the silver scales affect the balance of the razor ?

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

02-26-2013, 02:48 AM #10

Keep up the great pics with the story, the only ting I cast is lead and then send it down range between 950 and 2800 fps.

65Likes

65Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote