Results 31 to 37 of 37

-

04-12-2013, 03:58 PM #31

I just found this thread. I'm sorry I'm so late to the party!

For what it's worth, I do something similar to what Pierre outlined. I'm a bit of a nerd and like to get things straight to within 0.005" before final surface grinding of the spine. The only real difference is that I hold a wet rag on the edge of the blade to protect the temper, while heating the spine. I use a small jeweler's torch and work quickly.

Heat straightening does work. But, be prepared to ruin blades while you learn. Oh, I only use heat straightening for blades during construction. The edges are still 0.025" thick and the spines are 0.015" oversize. I have never done this on a finished, razor. I don't think I would waste my time. It would be very easy to make things worse at the edge.

I missed the whole thing on hardness testing. Here is some information that might come in useful: Rockwell C scale testing is only good for mateials over 0.028" thick at 62HRC. That is by spec. of the test. Under 0.028" you run in to the problem of innacurate readings due to compressing and cold working the steel under the indenter. You are also very likely to break hard samples that are thin. That is why they invented the micro-hardness tester. I have one, it is cool...

I hope this helps.

-

-

04-12-2013, 06:48 PM #32At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

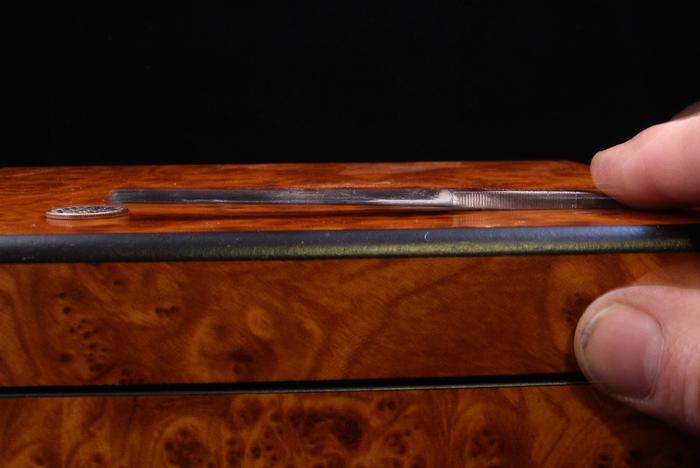

And another set of pics as to the problem when dealing with "Vintage Razors"

-

04-12-2013, 06:59 PM #33Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

04-12-2013, 07:57 PM #34At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

Well on this one razor above it is of course hitting the scales when closing which is pretty much the reason to mess with them at all.. Aslo I try and test them with my finger on the Pivot Hole as this gives the best indication of what is going to happen in the scales...

Restore Tip: Check the razor before you pin it in the scales two reasons

two reasons

1. It keeps you sane by letting you know it isn't that you can't make straight scales

2. It lets you know early on that you are going to have to start adjusting

Yes you will forget to check them, usually on some really fancy build

Being as that razor above is from a 2 day set I seriously doubt the owner wants me taking a torch to it

I seriously doubt the owner wants me taking a torch to it  so I used all the other methods available to get her closing right...

so I used all the other methods available to get her closing right...

Now these three below are "Bench Babies" from another experiment so I am going to try some tricks on them and see what happens, note that we are starting with 3 different tang thickness's too...

I just want to see what happens when I push the envelope, instead of being careful will be using the Vise and 3 rod method

will be using the Vise and 3 rod method

Last edited by gssixgun; 04-13-2013 at 12:43 AM.

-

04-14-2013, 05:48 PM #35

cold or hot?

My friends call me Bear.

-

04-14-2013, 05:54 PM #36At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

Hot with the Heat Block paste...

-

04-14-2013, 06:53 PM #37

looking forward to your results.

My friends call me Bear.

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote