Results 21 to 30 of 46

-

04-12-2013, 03:01 AM #21Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Have you considered whittling ? Anything is possible and the tools are cheaper. :<0)

I have a lathe I inherited when my father passed. He had some of the basic tools. I am looking at all the attachments myself and could spend a small fortune easily. I haven't used the lathe much but it is now sitting on my workbench ready to run again. Now I might not be able to make some of the beautiful things you see on this page as easy as my friends here do but like I started out saying. Nothing is impossible. Start with the basics and work your way up from there. Don't get overwhelmed by all the possibilities. I get the feeling you just want to try it out and make some things. I say go for it ! Great shops are not built overnight . They kind of grow with your skill level and the kind of work your interested in.Good judgment comes from experience, and experience....well that comes from poor judgment.

-

The Following User Says Thank You to 10Pups For This Useful Post:

Chevhead (03-20-2014)

-

04-12-2013, 03:39 AM #22Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

I have seen people turn usable brush handles on a drill press,lots of options.

-

04-12-2013, 05:41 AM #23Junior Member

- Join Date

- Mar 2013

- Location

- Oakland

- Posts

- 21

Thanked: 1

A lathe is more or less a drill press on its back.

-

04-12-2013, 09:43 AM #24Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

-

04-15-2013, 03:12 AM #25

Cheep tools are just that. A midi lathe by Delta or Jet is going to be your starting point. You dont need a chuck to turn brushes. I drill my brush pocket on the drill press then use my live center and a ¼ inch drive spur. You will need 2 or 3 gouges, a parting tool, a skew chisel is a good idea, maybe a fingernail gouge depending on the shapes you plan on turning. You can pick up a second hand lathe for a couple hundred that will last you a long time. Factor in another $300 or so in tools, you will need a sharpener for the tools, I use a 1 inch strip sander that I reversed and put a lathe tool angle guide on, add another couple hundred for that. You will need a dust collector and no a shop vac will not do the job. For exotic wood you need something with a 3 micron filter on it. I have a garage shop with a large Jet canister dust collector and 4 inch hard line around the shop with blast gates for all of the tool stations. A bit overkill for you but figure $500 for a decent dust collector and you will need a respirator visor. I use a Trend with a 2 micron filter on it, about another $300 for that. Dont skip on dust collection unless you just want to kill yourself. Cocobolo dust can put you in the hospital, most exotic woods are very toxic.

You will end up with about $1500 in a bare bones setup, maybe around $800 if you get luckey on second hand tools. Skip harbor freight, keep with the good lathe tools, Sorby makes good lathe tools but you can spend $90 on one tool. Then take a class or two so you dont kill yourself or rip off a couple fingers. It is a fun hobby but can get expensive fast. Done incorrectly, it can be very dangerous.

-

The Following User Says Thank You to cannonfodder For This Useful Post:

BKratchmer (05-03-2013)

-

04-15-2013, 03:34 AM #26Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Sorry cannon,But i disigree with most you say,you do need chucks if your going to turn quality handles without spur marks.

hepa filter shop vacs work fine for dust collection,have been turning CoCo for 30 yrs with zero issues.

why spend $90 for a HSS sorby (great tools)when you can go carbide for half that.

I like finished inlayed ends on my brushes,you cannot do that turning between centers.

You need chucks for quality work.

-

04-15-2013, 03:49 AM #27Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

A couple of other things to consider. If you can make a knife or a razor, you can make your own lathe chisels. If you have a belt grinder, you can free hand sharpen your chisels. IMO, I agree with pixelfixed, I wouldn't want to turn handles without a chuck. Like everything - there are many ways to skin a cat, and none of them are wrong - assuming they work for someone.

Last edited by skipnord; 04-15-2013 at 03:51 AM.

-

04-15-2013, 04:27 AM #28

Excellent advice! Start simple. If you don't like Harbor Freight, try Grizzly. Start with a few basic tools.

I would advise looking for a lathe with a #2 Morse Taper (MT) headstock and tailstock as accessories are easier to get.

Google Got Wood or Craft Supplies USA to get wood at decent prices. You can also use bottle stopper blanks if you're not turning big handles.

-

04-15-2013, 04:10 PM #29Junior Member

- Join Date

- Mar 2013

- Location

- Oakland

- Posts

- 21

Thanked: 1

Another option I'll pass on is find a local chapter of the american woodturners association assuming they have a chapter and ya know... You're american.. Take a class at woodcraft or here in the sf bay area I do believe The Crucible teachers classes though I doubt that's the most economical option. That place still is awesome. I took an intro to blacksmithing class there a while back.

Or even try and find a local srp member who would be willing to show you how to take the corners off. I bought a craigslist lathe and did a little spindle turning on it before I jumped all the way in. Thing is currently sitting into my storage, needs to go back on craigslist for the song I paid for it.

-

04-16-2013, 03:12 AM #30

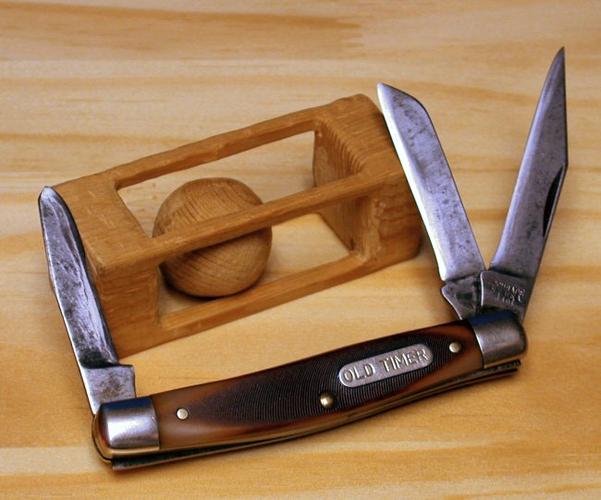

Darn. Now you tell me. So I guess these

and these

and these

or

or the other 1200ish brushes are any good.

You can certainly turn a good brush between centers. A thin kerf parting tool and some practice is all it takes but I spend 20 or more hours a week in front of a lathe. If you are doing inserts or in-line boring you certainly need a 4 jaw chuck but for a basic starter setup it is not needed but to each his own.

A hepa filter for a shop vac is not your average shop vac but if you turn a few thousand parts a year plus cabinets, tables, etc... replacing the hepa filter bags will rack up more than enough cost in a year to purchase a good canister dust collector. I also run a ceiling mounted 2 micron air filtration system. If you expand in the future you will need a lot more CFM for collection than a shop vac can muster but as I said, that is overkill if the only thing you are going to do is suck dust from a lathe and only turn one or two parts a month. The point is you need a fine micron filter for exotic woods. I know more than a few people that spent time in ICU after breathing dust. I would suggest anyone wanting to work exotic or even domestic wood read up on the wood toxicity, just google it and there are pages of information. I know folks that wont even turn some woods without a full Tyvek suit because of the reaction induced by some of the exotic woods.

That aside, I would love to know where you are getting carbide lathe tools. The only carbide tools I have seen are small hollow form tools and they have been as expensive or more so than a HSS. You can get good cryo treated Pinnacle tool but they are no less expensive, often more expensive than a SorbyLast edited by cannonfodder; 04-16-2013 at 03:18 AM.

-

The Following User Says Thank You to cannonfodder For This Useful Post:

BKratchmer (05-03-2013)

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote